Method and device for cleaning an exhaust gas flow of a combustion engine

A technology of exhaust flow and internal combustion engine, which is applied in the field of exhaust flow and exhaust flow devices of exhaust gas booster internal combustion engines, and can solve the problems of reducing the proportion of nitrogen oxides and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

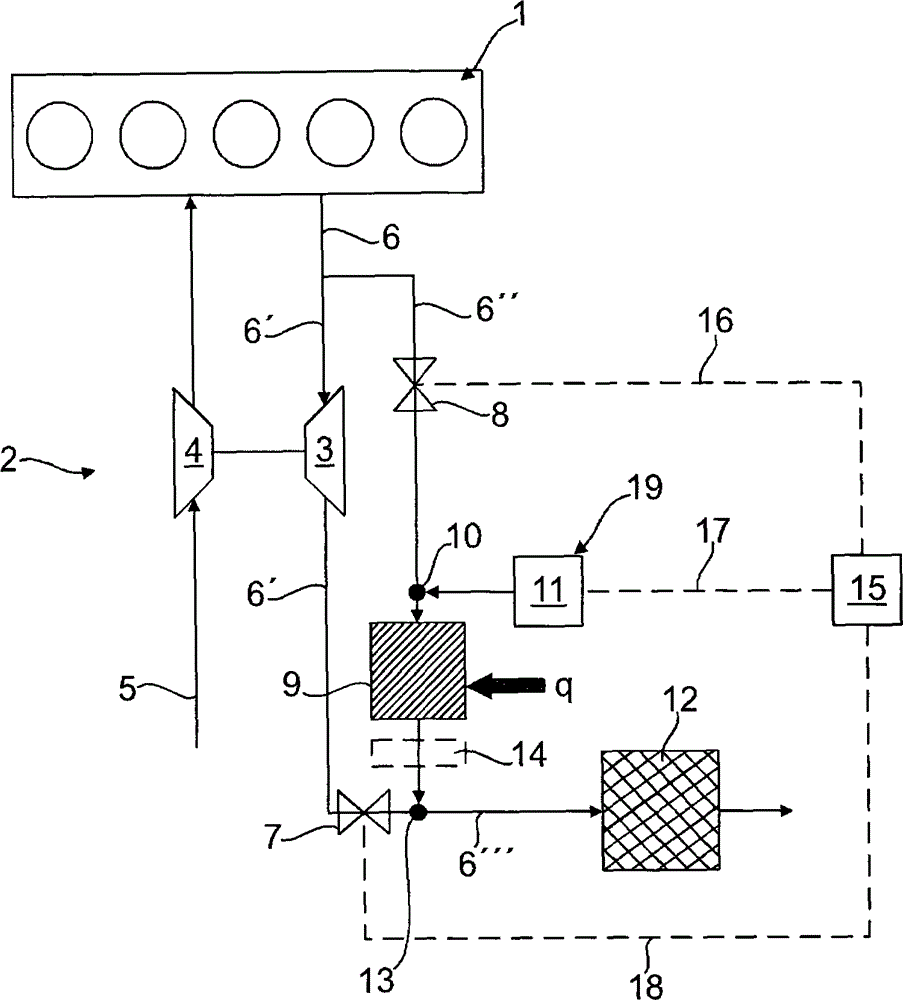

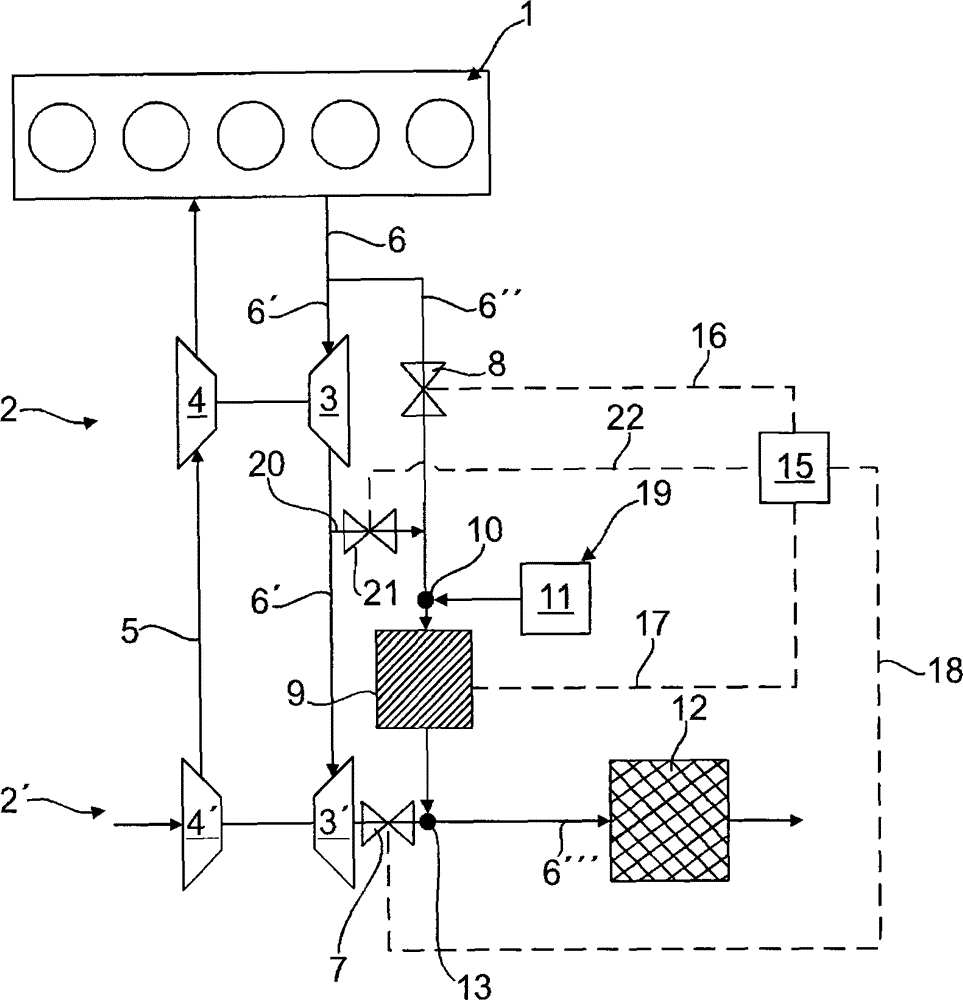

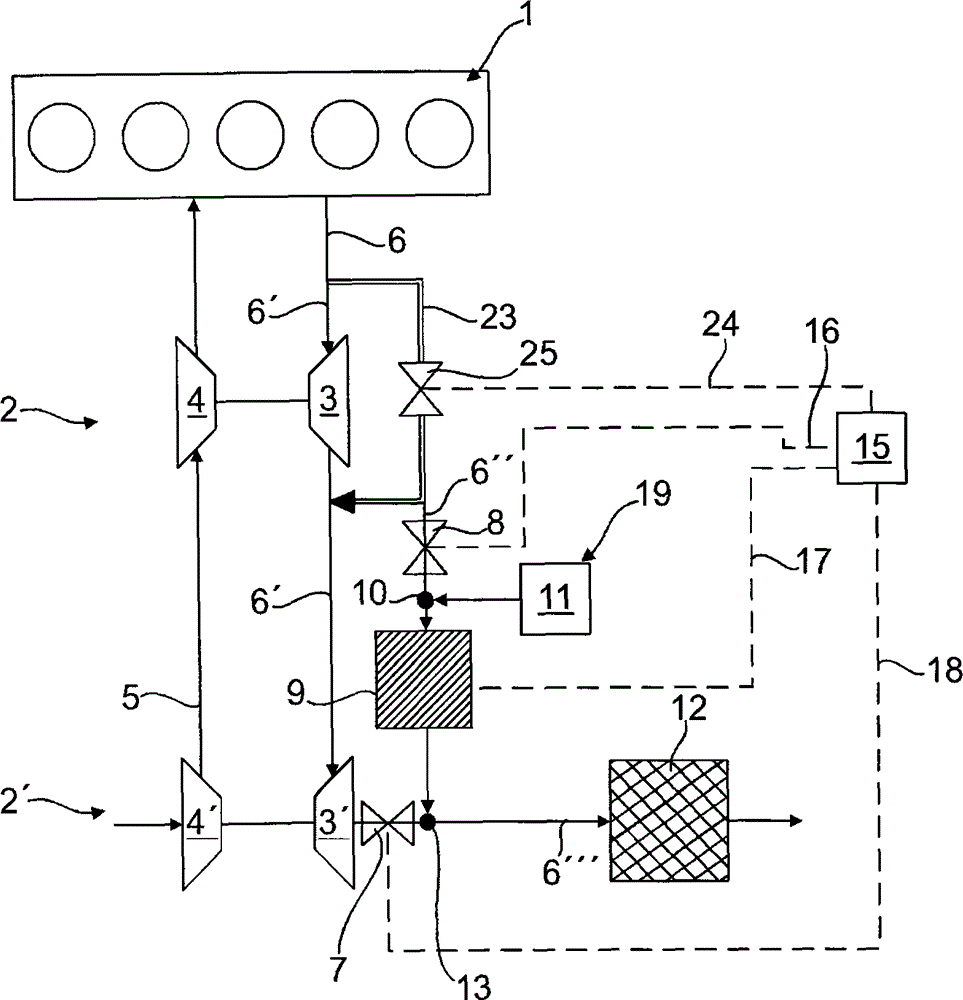

[0039] exist figure 1 2 schematically shows the use of the method according to the invention and a first embodiment of the device according to the invention for purifying the exhaust gas flow of a one-stage supercharged internal combustion engine 1 by means of an exhaust gas turbocharger 2 . The exhaust gas turbocharger 2 has an exhaust gas turbine 3 and a supercharger 4 . Charge air 5 is supercharged by means of supercharger 4 , wherein supercharger 4 is driven by means of exhaust gas turbine 3 .

[0040] Upstream of the exhaust gas turbine 3, the exhaust gas flow 6 from the internal combustion engine 1 branches into a main exhaust gas flow 6' and an exhaust gas partial flow 6". A variable throttle mechanism 7 configured as a valve. Viewed in the flow direction, a further variable throttle mechanism 8 is arranged in the exhaust gas subflow 6 ″. A reactor 9 is arranged downstream of the variable throttle 8 in the exhaust gas split 6 ″. Upstream of the reactor 9 there is a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com