Negative plate of inert composite electrode adopting EFT and preparation method thereof and electrolytic equipment containing negative plate

A technology for electrolysis equipment and electrode plates, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of easy fouling, high consumption of electrode plate materials, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

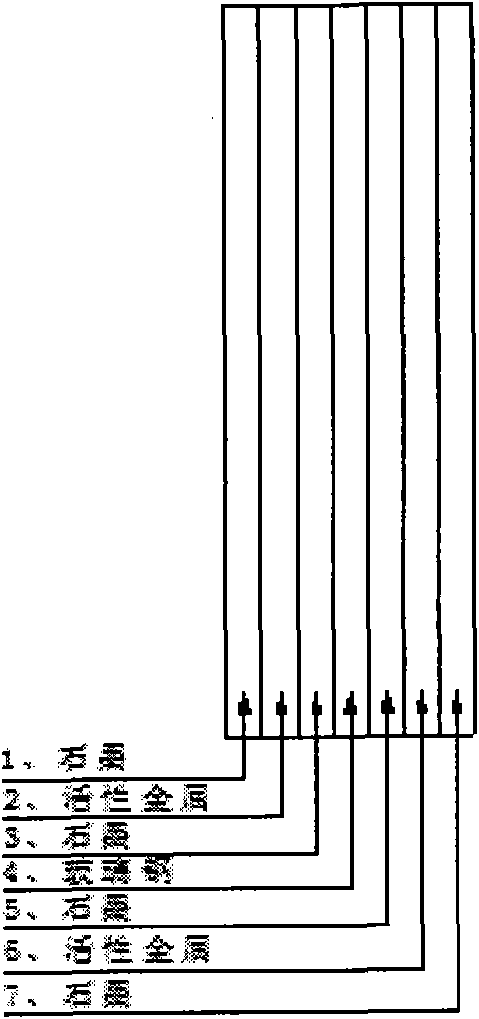

[0117] Embodiment 1. cathode plate, a 7-layer structure composed of graphite layer, iron layer after sprinting, graphite layer, glass fiber reinforced plastic layer, graphite layer, iron layer and graphite layer after sprinting

[0118] Step 1: Preparation of Graphite Layer

[0119] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into 4 composite flat plates with a thickness of 0.8mm.

[0120] Step 2: Preparation of FRP layer

[0121] Use high-quality epoxy resin and glass fiber to press into a composite plate with a thickness of 0.6mm.

[0122] Step 3: Preparation of active metal layer

[0123] Two pieces of active metallic iron materials with a thickness of 1mm are selected for sprint treatment.

[0124] Step 4: Preparation of transition plate

[0125] The 0.8mm graphite layer, the 1mm thick punctured active metal iron layer and the 0.8mm graphite layer were sequentially bonded and flattened with glue to obtain two composite m...

Embodiment 2

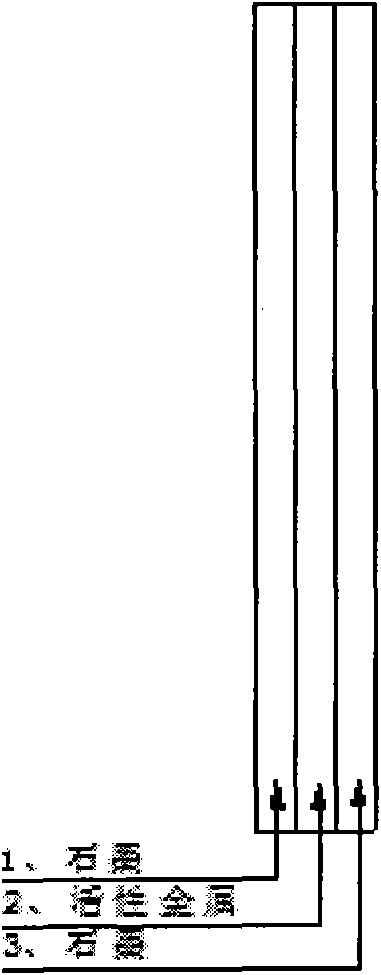

[0127] Embodiment 2. cathode plate, a 3-layer structure consisting of graphite layer, aluminum layer and graphite layer in turn

[0128] Step 1: Preparation of Graphite Layer

[0129] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into 2 composite flat plates with a thickness of 0.6mm.

[0130] Step 2: Preparation of active metal layer

[0131] The active metal aluminum material with a thickness of 1mm is selected.

[0132] Step 3: Preparation of transition plate

[0133] After the 0.6mm graphite layer, the 1mm thick active metal aluminum layer and the 0.6mm graphite layer are glued and flattened sequentially, the cathode plate of the present invention is obtained.

Embodiment 3

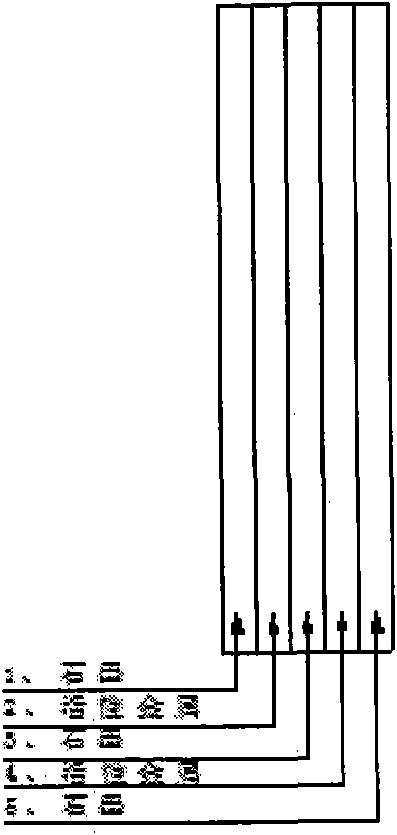

[0134] Embodiment 3. cathode plate, 5 layer structure that is formed successively by graphite layer, aluminum layer, graphite layer, aluminum layer, graphite layer

[0135] Step 1: Preparation of Graphite Layer

[0136] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into 3 composite flat plates with a thickness of 0.8mm.

[0137] Step 2: Preparation of active metal layer

[0138] The active metal aluminum material with a thickness of 1mm is selected.

[0139] Step 3: Preparation of transition plate

[0140] After the graphite layer, the active metal aluminum layer, the graphite layer, the active metal aluminum layer and the graphite layer are sequentially glued and flattened, the cathode plate of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com