Positive plate of inert composite electrode adopting EFT and preparation method thereof and electrolytic equipment containing positive plate

A technology of electrolysis equipment and electrode plates, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of short service life, easy aging, easy fouling, etc., and achieve the goal of not being easily corroded, protecting the service life, and ensuring stable distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

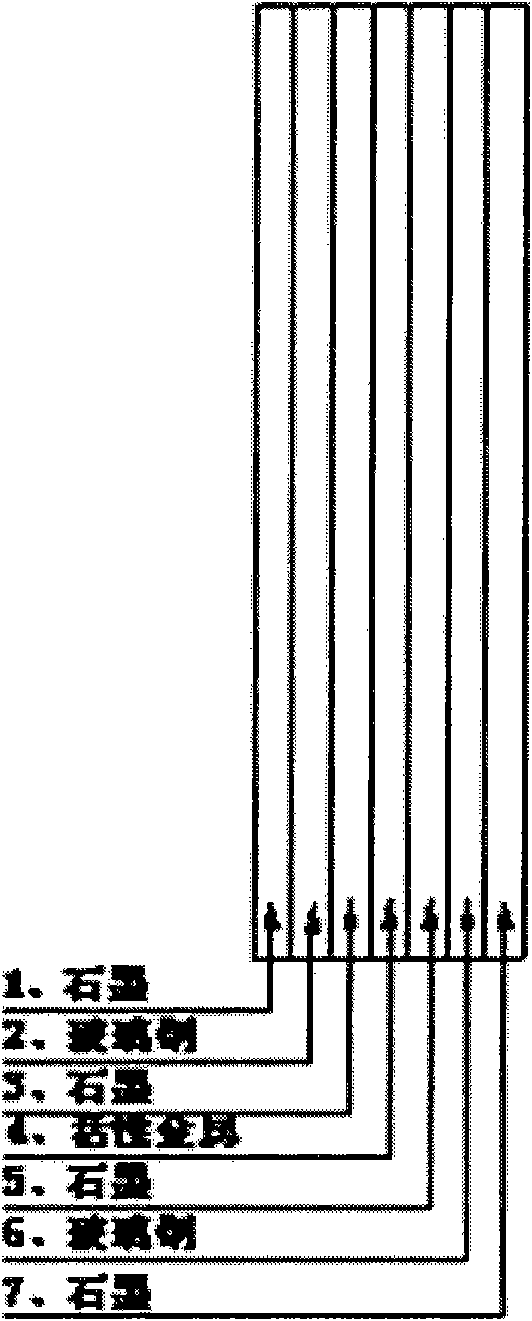

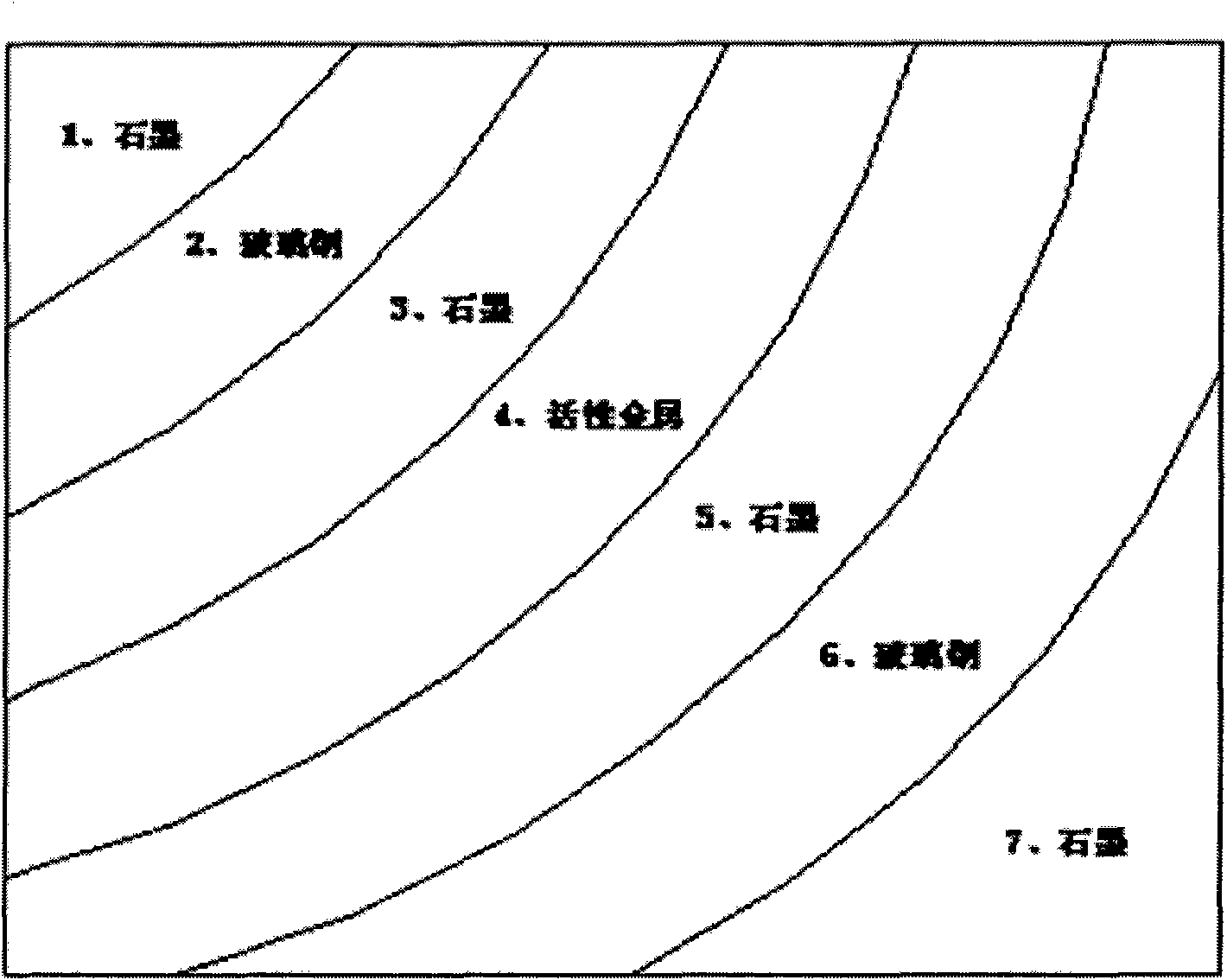

[0108] Embodiment 1. anode plate, is made up of graphite layer, glass fiber reinforced plastic layer, graphite layer, active metal layer, graphite layer, glass fiber reinforced plastic layer, graphite layer 7 layer structure

[0109] Step 1: Preparation of Graphite Layer

[0110] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into two composite flat plates with a thickness of 0.5mm and 0.8mm.

[0111] Step 2: Preparation of FRP layer

[0112] Use high-quality epoxy resin and glass fiber to press into two composite flat plates with a thickness of 0.5mm.

[0113] Step 3: Preparation of active metal layer

[0114] Use an aluminum plate with a thickness of 1mm.

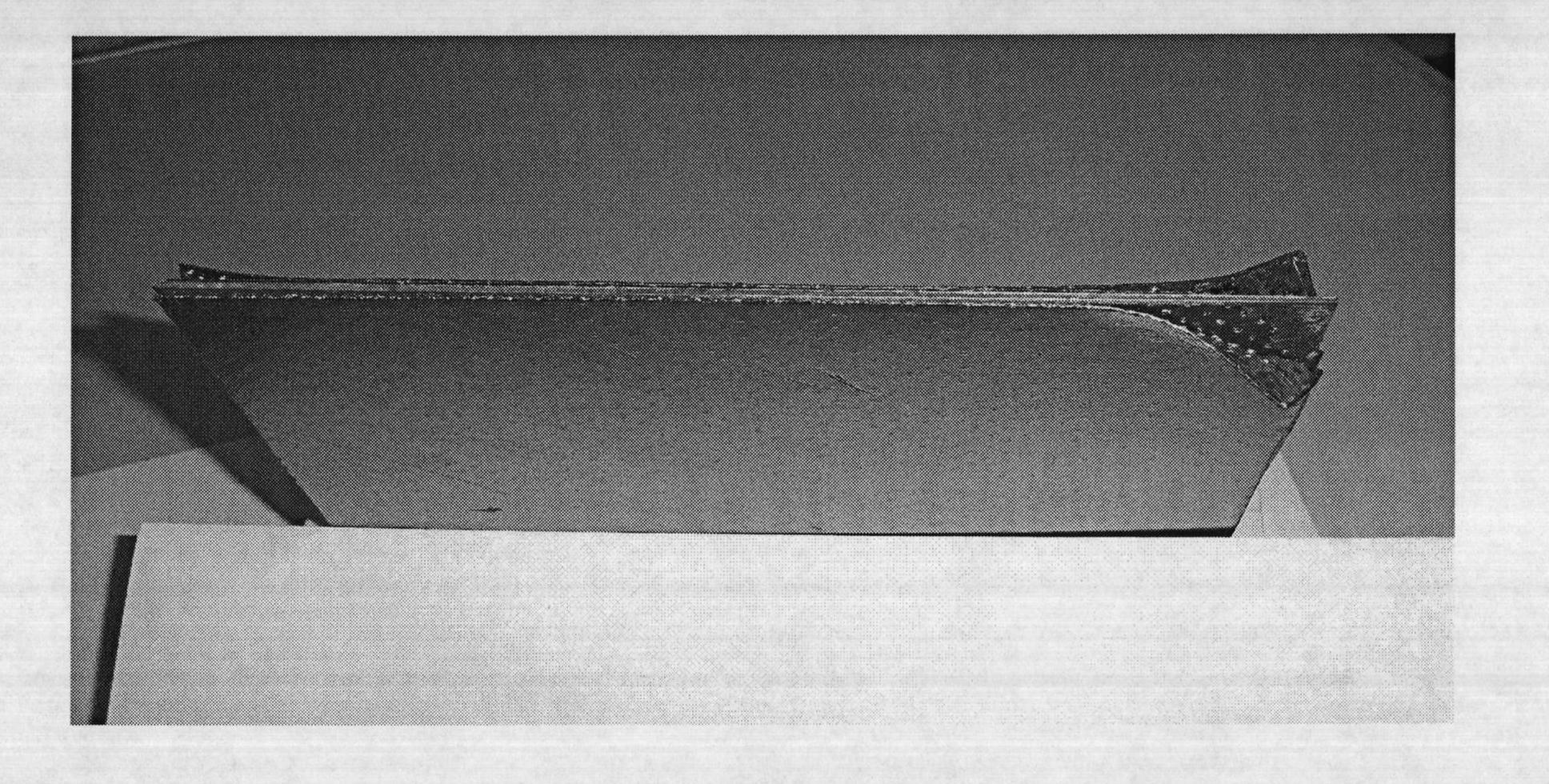

[0115] Step 4: Preparation of the anode plate

[0116] After the 0.5mm graphite layer, the 0.5mm fiberglass layer and the 0.8mm graphite layer are bonded and flattened with conductive adhesive in sequence, two identical outer layer composite materials are obtained, and the...

Embodiment 2

[0117] Embodiment 2. anode plate, is made up of graphite layer, glass fiber reinforced plastic layer, graphite layer, active metal layer, graphite layer, glass fiber reinforced plastic layer, graphite layer 7-layer structure

[0118] Step 1: Preparation of Graphite Layer

[0119] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into four composite flat plates with a thickness of 1mm.

[0120] Step 2: Preparation of FRP layer

[0121] Use high-quality epoxy resin and glass fiber to press into two composite flat plates with a thickness of 0.8mm.

[0122] Step 3: Preparation of active metal layer

[0123] Use an aluminum plate with a thickness of 0.8mm.

[0124] Step 4: Preparation of the anode plate

[0125] After the 1mm graphite layer, the 0.8mm FRP layer and the 1mm graphite layer are bonded and flattened with conductive glue in sequence, two identical outer layer composite materials are obtained, and then the two composite mate...

Embodiment 3

[0126] Embodiment 3. anode plate, is made up of graphite layer, fiberglass layer, graphite layer, active metal layer, graphite layer, fiberglass layer, graphite layer 7 layer structure

[0127] Step 1: Preparation of Graphite Layer

[0128] Select high-quality expanded graphite worms with a content of more than 99.8% and press them into four composite flat plates with a thickness of 0.6 mm.

[0129] Step 2: Preparation of FRP layer

[0130] Use high-quality epoxy resin and glass fiber to press into two composite flat plates with a thickness of 0.8mm.

[0131] Step 3: Preparation of active metal layer

[0132] Use an aluminum plate with a thickness of 1.2mm.

[0133] Step 4: Preparation of the anode plate

[0134] After the 0.6mm graphite layer, the 0.8mm FRP layer and the 0.6mm graphite layer are bonded and flattened with conductive glue in sequence, two pieces of the same outer layer composite material are obtained, and then the two composite materials are placed on the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com