Guide section device for billet continuous casting machine

A billet continuous casting and guide section technology, which is applied in the field of guide section devices, can solve the problems of lack of cooling method, short life of guide rollers, complicated disassembly and assembly, etc., so as to improve the continuous working time, prevent radial runout, disassemble and repair handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

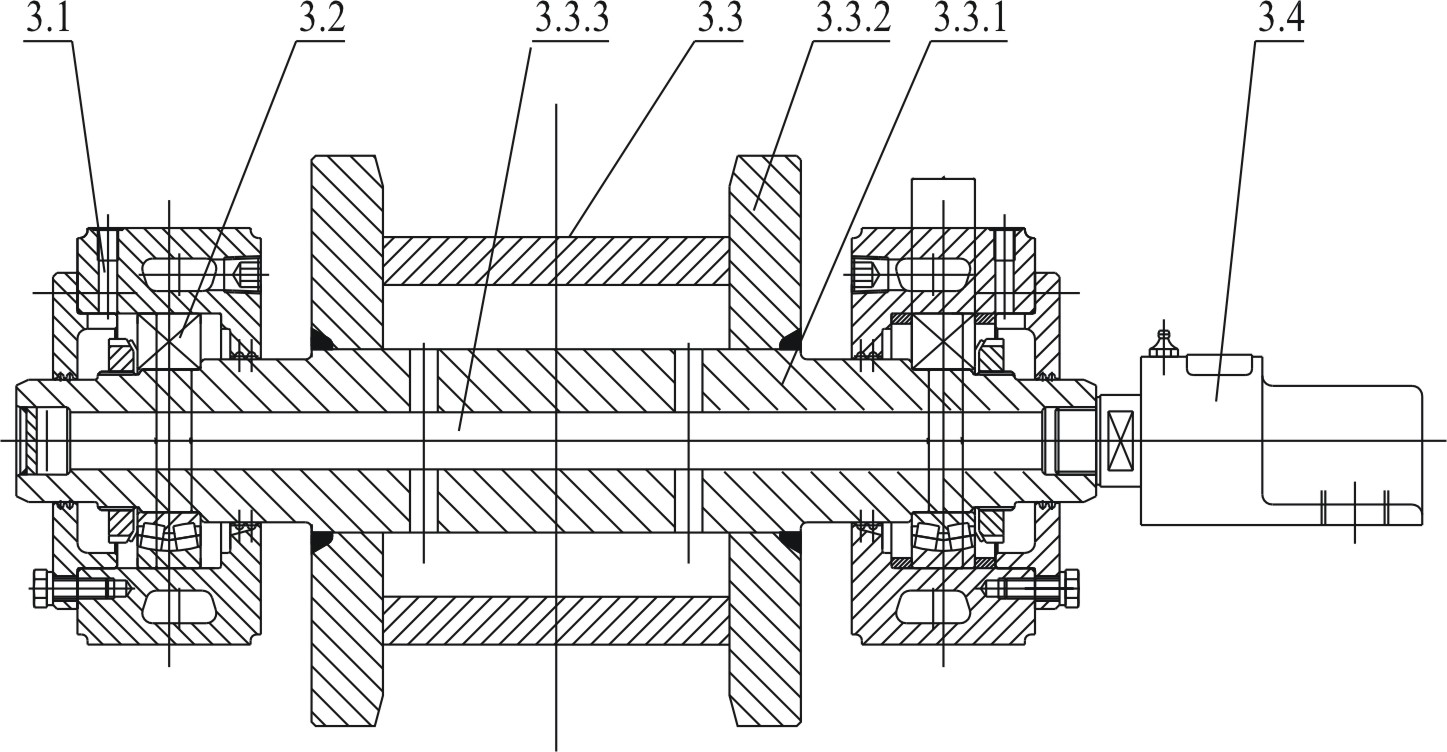

[0020] As shown in the figure, a guide section device for a billet continuous casting machine according to the present invention includes a guide roller base 2 , a guide roller 3 , a protection platform 1 and a pressing roller 4 .

[0021] Wherein: the guide roller base 2 is a box-shaped structure welded by Q235 steel plates, fixed on the structural platform of the whole device, and used to support the guide roller 3 and the like.

[0022] The guide roller 3 is assembled on the guide roller base 2 for supporting the billet 5 . It includes water-cooled bearing housing 3.1, roller bearing 3.2, roller 3.3 and swivel joint 3.4. The water-cooled bearing seat 3.1 is made of cast steel, which has high strength and low cost. The roller 3.3 is set on the water-cooled bearing housing 3.1 through the roller bearing 3.2. Roller bearing 3.2 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com