Electronic system multi-goal reliability allowance design method based on EDA technology

An electronic system and design method technology, applied in the field of electronics, can solve the problems of large fluctuation of system quality characteristics, no improvement in quality characteristics, and only concerned about product stability and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

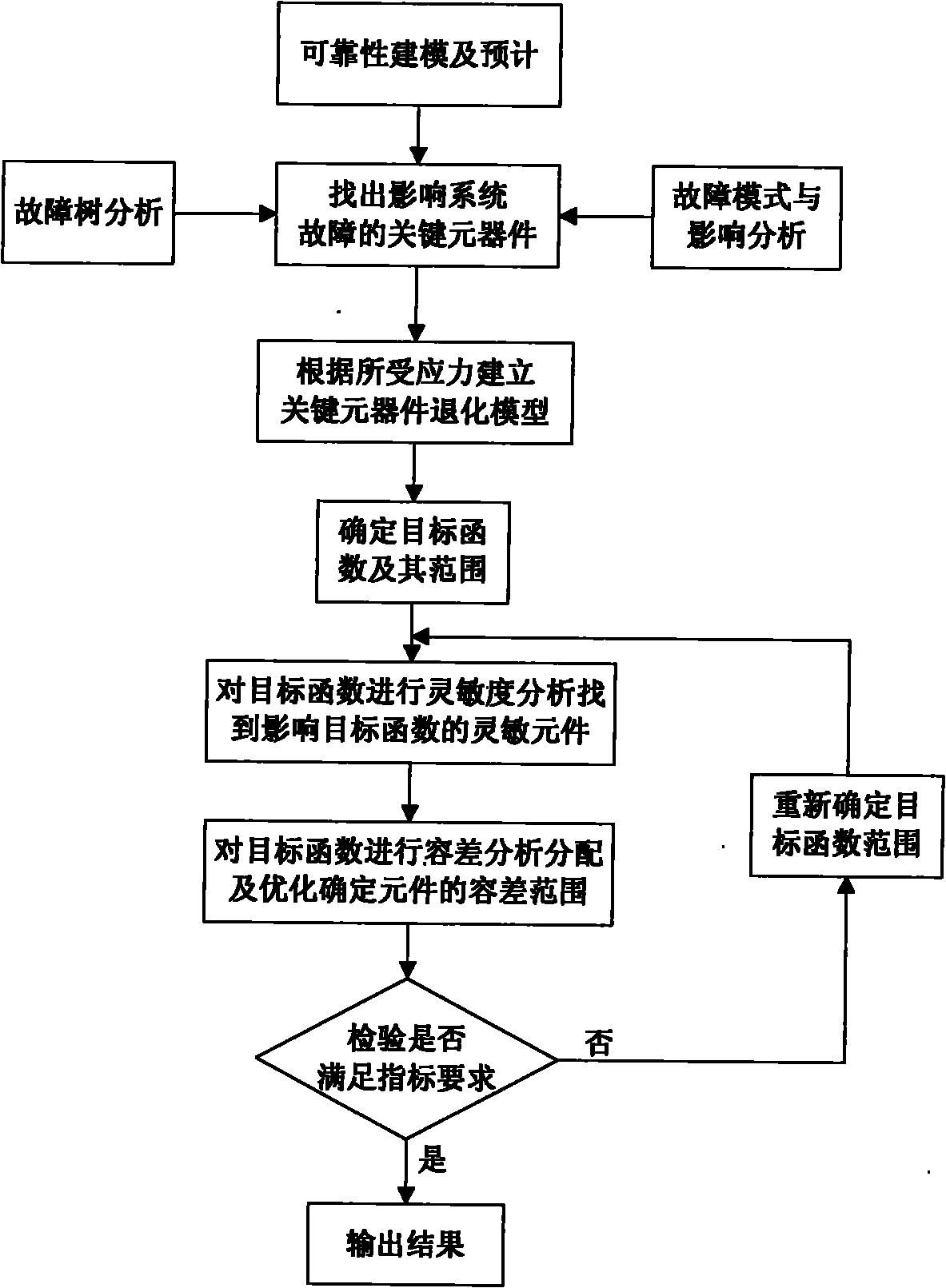

[0016] Example 1: Combining figure 1 , the present invention is based on the electronic system multi-objective reliability tolerance design method of EDA technology, and the steps are as follows:

[0017] Step 1: Establish a Pspice simulation model of the electronic system, and use reliability analysis methods such as reliability modeling and reliability prediction, failure mode and effect analysis, and fault tree analysis to find key components that affect electronic system failures;

[0018] Step 2: Establish the reliability degradation model of key components according to the environmental conditions of the electronic system and the stress loads on the components;

[0019] Step 3: According to the degradation model analysis of components, find the key stress factors that affect the life of key components, and use them as the objective function of multi-objective tolerance design, according to the reliability index of the system or according to the actual stress of the compo...

Embodiment 2

[0024] Example 2: Combining figure 1 , the present invention is based on the electronic system multi-objective reliability tolerance design method of EDA technology and comprises the following steps:

[0025] Step 1: Find the key components that affect the failure of the electronic system. Use reliability modeling and prediction, failure mode and effect analysis (FMEA) and fault tree analysis (FTA) methods to analyze the reliability of the system, and determine the key components that affect the reliability of the system. Assume that the object analyzed by the multi-objective tolerance design method is an electronic system S, which is composed of n components connected to each other and has no redundant structure. When any component fails, the system cannot work normally.

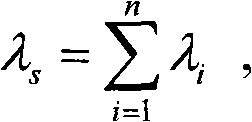

[0026] (1) Establish a reliability block diagram model, which is a pure series model. It can be known that the basic reliability mathematical model of the system is:

[0027] λ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com