High-pressure oil rail with novel structure

An oil rail, high-pressure technology, applied in engine components, machines/engines, charging systems, etc., can solve problems such as increasing the development cost of parts and components, resource management costs of parts, inconvenient disassembly for inspection and maintenance, and complex engine structure. , to achieve the effect of reducing development and management costs, facilitating maintenance and maintenance, and reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

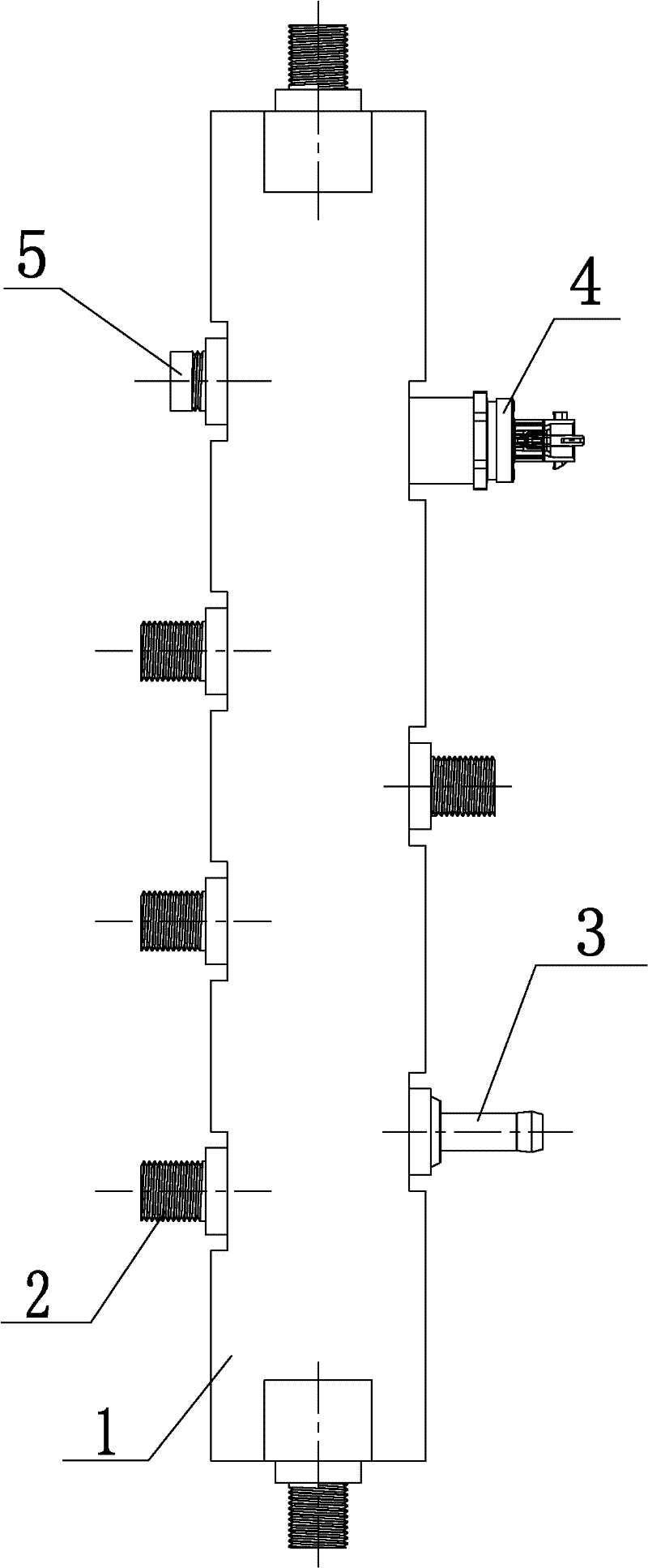

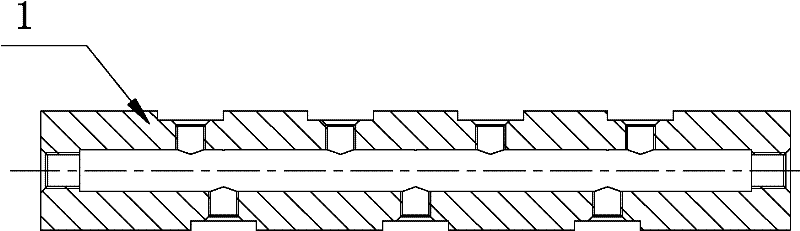

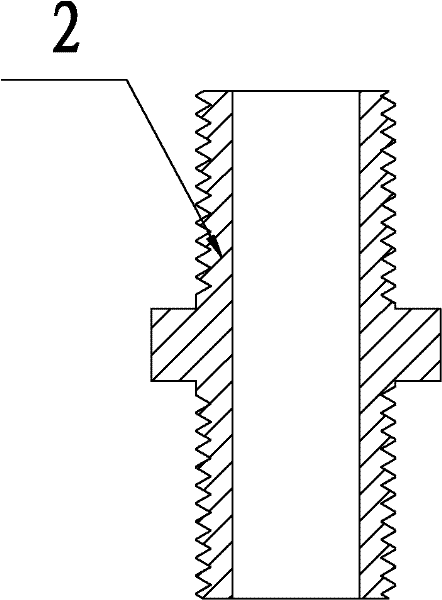

[0015] see Figure 1 to Figure 4 , a high-pressure oil rail, including an oil rail body 1; an oil outlet joint 2, an oil return joint 3 and an oil pressure sensor seat 4 installed on the oil rail body 1; interface, the interfaces on both sides are distributed in a staggered manner, the oil return joint 3 and the oil pressure sensor seat 4 are installed on the two interfaces on the side wall of the oil rail body, and the oil outlet joint 2 and the plugging member 5 are installed on the other interfaces. Both ends of the oil rail body are also provided with interfaces for installing oil outlet joints. In the above structure, the oil outlet joint 2, the oil return joint 3, and the oil pressure sensor seat 4 are all threaded to the oil rail body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com