Integrated immersion quenching device of steel bottle quenching-and-tempering line

A quenching device and production line technology, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve problems such as poor straightness of steel cylinder and metallographic structure, poor quenching liquid temperature, uncertain overall stability factor, etc. The quenching effect is good, the structure is simple, and the effect of reducing the driving burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

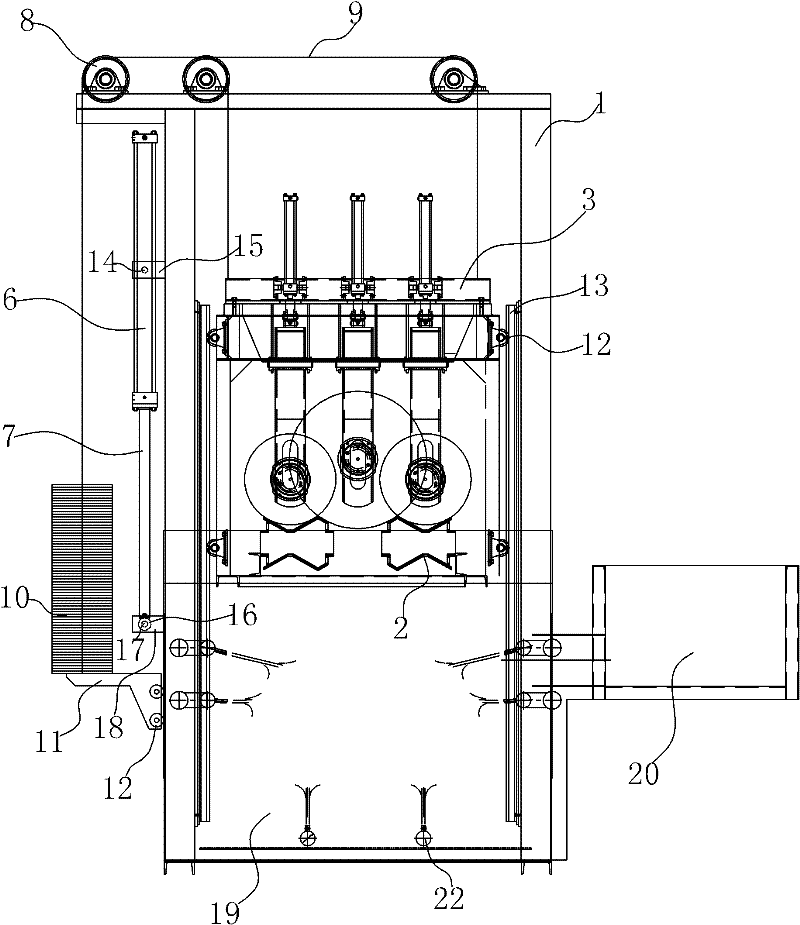

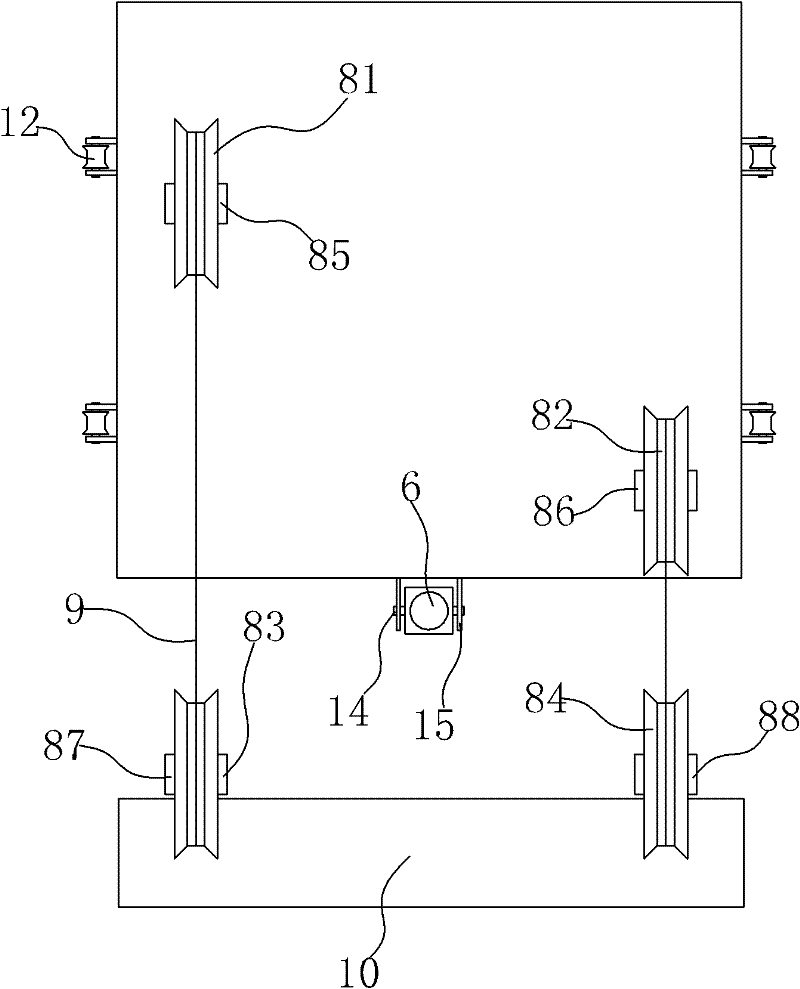

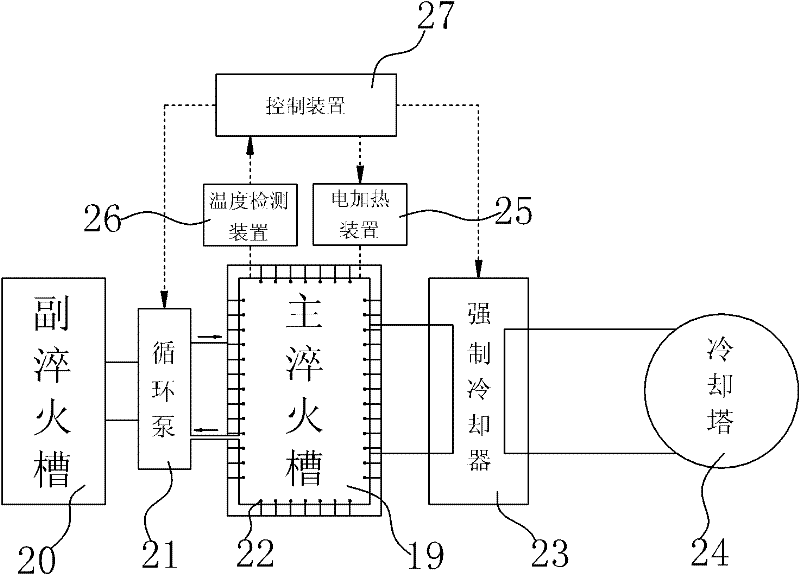

[0020] refer to figure 1 , the quenching frame lifting device, including the main frame 1 and the quenching frame 3 with the steel cylinder clamping mechanism 2, the steel cylinder clamping mechanism 2 includes supporting rollers and pressing mechanisms, etc., a quenching tank is provided under the quenching frame, and the quenching tank includes The main quenching tank 19 and the secondary quenching tank 20 filled with quenching liquid. The side of the quenching frame 3 is provided with a quenching frame roller 4, and the main frame 1 is provided with a first guide rail 5 cooperating with the quenching frame roller 4, which ensures easy assembly and stable operation. The quenching frame roller 4 is arranged, and the quenching frame roller 4 cooperates with the first guide rail clearance of the main frame. The quenching frame 3 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com