Digital controlled lathe for processing piston with non-circular section

A technology of CNC lathes and non-circular sections, applied in the field of CNC lathes, can solve the problems of error, complex structure, gravity balance mechanism needs to be considered in the column, and achieve the advantages of reducing inertia, small length-diameter ratio of piston, and lightweight tool seat structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

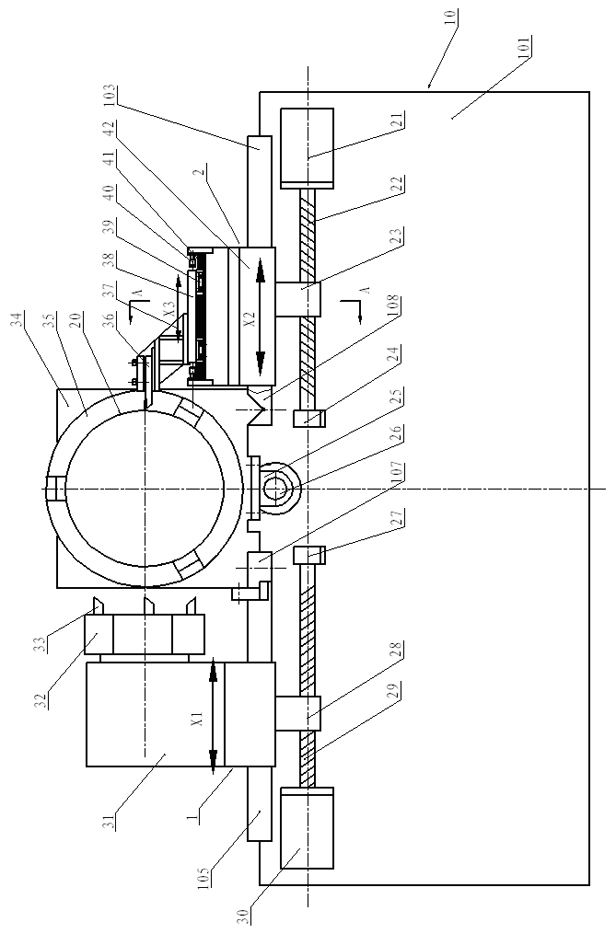

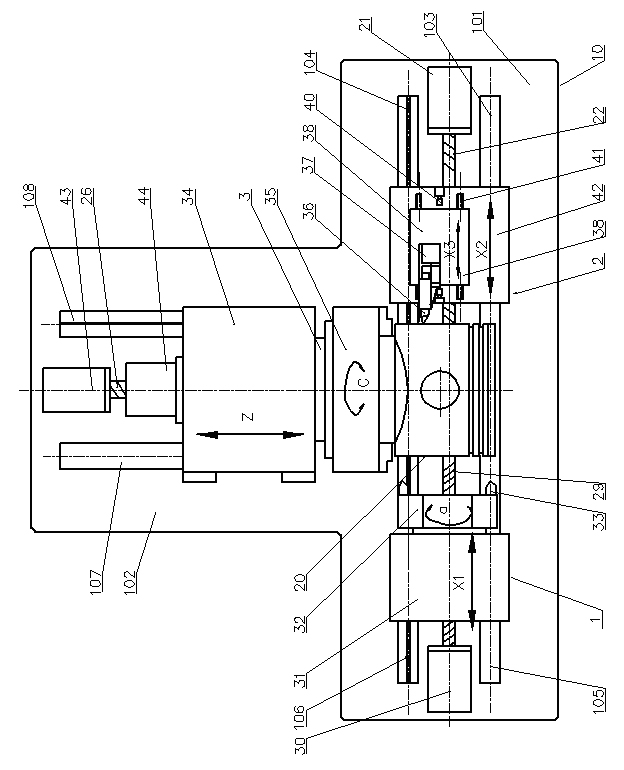

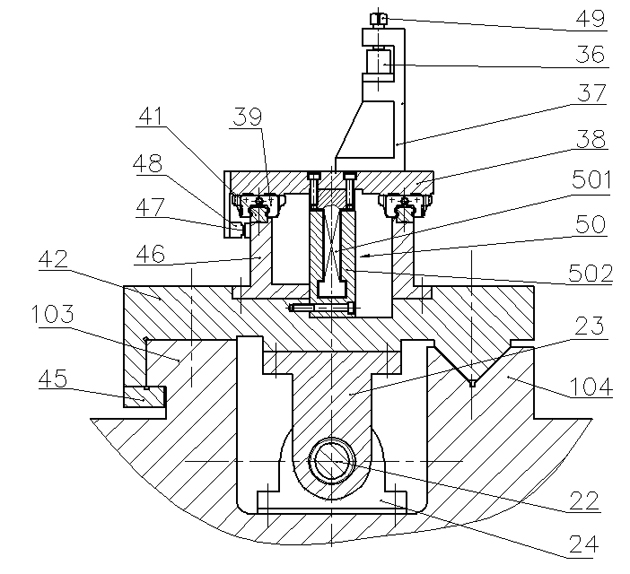

[0023] Example: attached figure 1 is the front view of the machine tool, attached figure 2 for figure 1 The top view, which expresses the contour shape of the so-called inverted "T"-shaped piston CNC lathe. The bed 10 is composed of the front bed 101 and the rear bed 102; the headstock 34 is installed on the rear flat guide rail 107 and the rear V guide rail 108 of the rear bed 102, and the main movement (C axis) of the machine tool is fixedly connected with the headstock Driven by the servo motor 44 of 34, the Z-axis feed movement along the axis of the piston 20 is driven by the Z-axis servo motor 43 to rotate the ball screw 26 and drive the spindle box 34 along the straight line of the rear flat guide rail 107 and the rear V guide rail 108 through the nut seat 25 Movement; the radial X-axis feed along the piston 20 is divided into three independent drives of the X1 axis, the X2 axis and the X3 axis, wherein the X1-axis feed is driven by the X1-axis servo motor 30 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com