Diaphragm for speaker, speaker, and method for producing diaphragm for speaker

A loudspeaker and vibrating membrane technology is applied to the manufacturing field of loudspeaker vibrating membranes, loudspeakers and loudspeaker vibrating membranes, and can solve the problems of difficulty in reproducing high-quality sound of digital devices, occupying loudspeaker manufacturing costs, insufficient rigidity of vibrating membranes, etc. To achieve the effect of widening reproduction bandwidth, improving rigidity and good sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

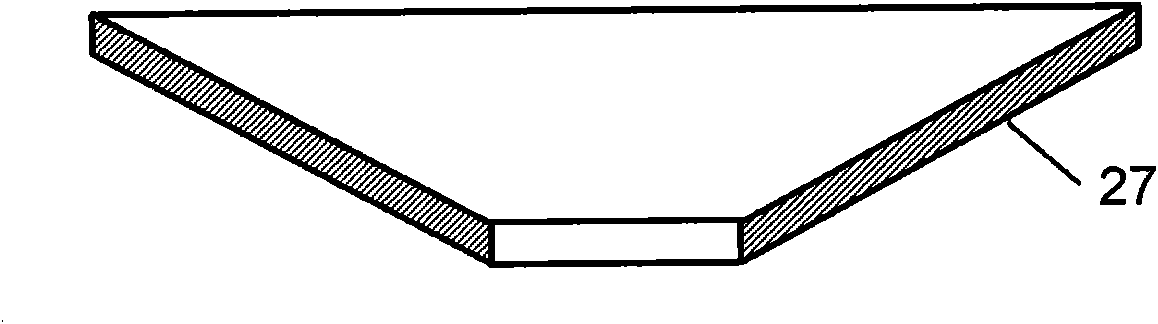

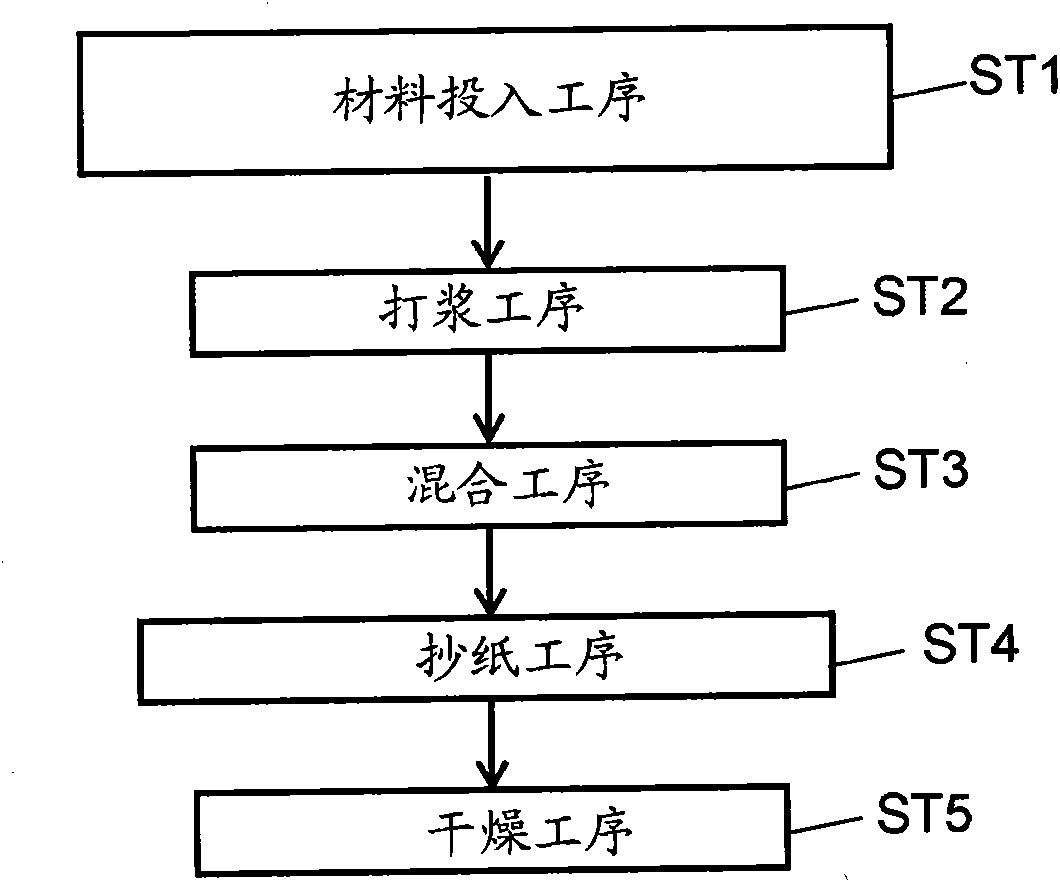

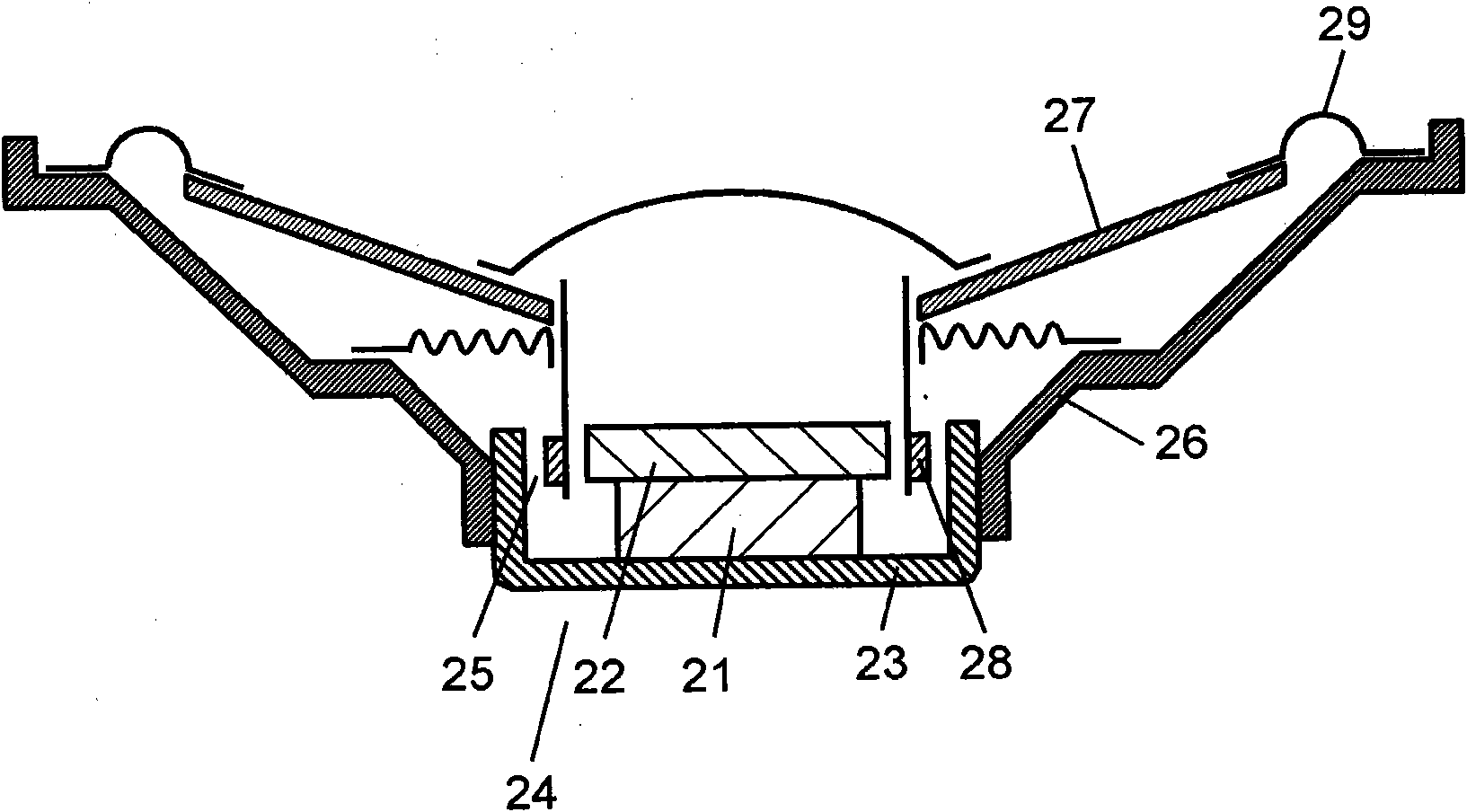

[0036] figure 1 It is a cross-sectional view of the speaker diaphragm in Embodiment 1 of the present invention. exist figure 1 Among them, the vibrating membrane 27 uses at least 5wt% or more fibers extracted from bamboo leaves, which is a vibrating membrane for a speaker manufactured by a papermaking process. Highly rigid natural fibers contain a large amount of silica compounds. In addition, since the shape and size of silica compounds vary depending on the type and part of the plant, by using fibers (pulp) extracted from plant types and parts containing a large amount of silica compounds, it is possible to improve Rigidity of the paper-made diaphragm, and further improvement of the sound quality of the speaker diaphragm.

[0037] That is, in general, it is important to select natural fibers as materials by paying attention to the amount of silica compounds in plants called plant opal.

[0038] In general, in terms of plant parts, the silica compound exists most in the p...

Embodiment 1

[0044] Bamboo leaves with a silicon concentration of 5030 μgSi / g and a weight of about 800 g were immersed in 400 g of water by chemical absorption photometry (molybdenum blue / yellow method), and then processed at room temperature for 10 minutes at 20 rpm using a pressurized kneader with a volume of 3 L. . The Canadian standard freeness (カナダ standard freeness) of this bamboo fiber is 730ml. A 16-cm circular speaker diaphragm was produced from the pulp by a papermaking process. Measurement was performed in a 1 Hz tension mode, and the sound velocity obtained from the elastic modulus at 20° C. was 2250 m / s.

[0045] Generally, there is a correlation between the speed of sound and the high-frequency limit frequency (high-range limit cycle number), and in order to make the reproduction range reach the human audible threshold, which is around 20kHz, the speed of sound basically needs to be around 1800m / s from a practical point of view.

Embodiment 2

[0047] According to the fiber ratio of common wood kraft pulp (NUKP) 70wt%, bamboo fiber 30wt% of embodiment 1, carry out the same operation as embodiment 1, manufactured 16cm circular loudspeaker diaphragm by papermaking process. The speed of sound is 2100m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com