Seatbelt retractor

A seat belt retractor and webbing technology, which is applied in the direction of seat belts, belt retractors, transportation and packaging, etc. in the car, and can solve the problem of the limit of the size of the thickened end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, an embodiment of a seat belt retractor according to the present invention will be described in detail with reference to the accompanying drawings.

[0065] rough structure

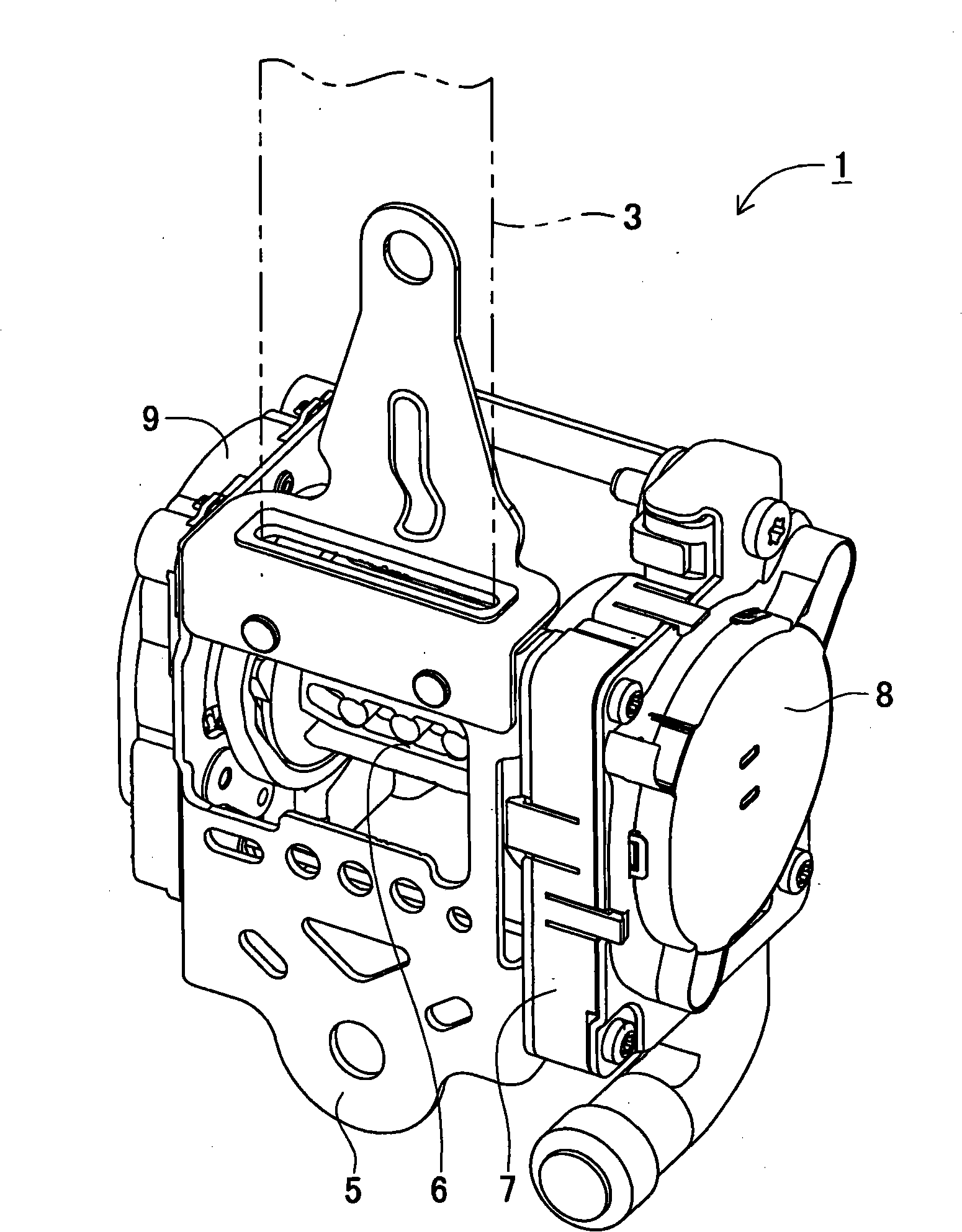

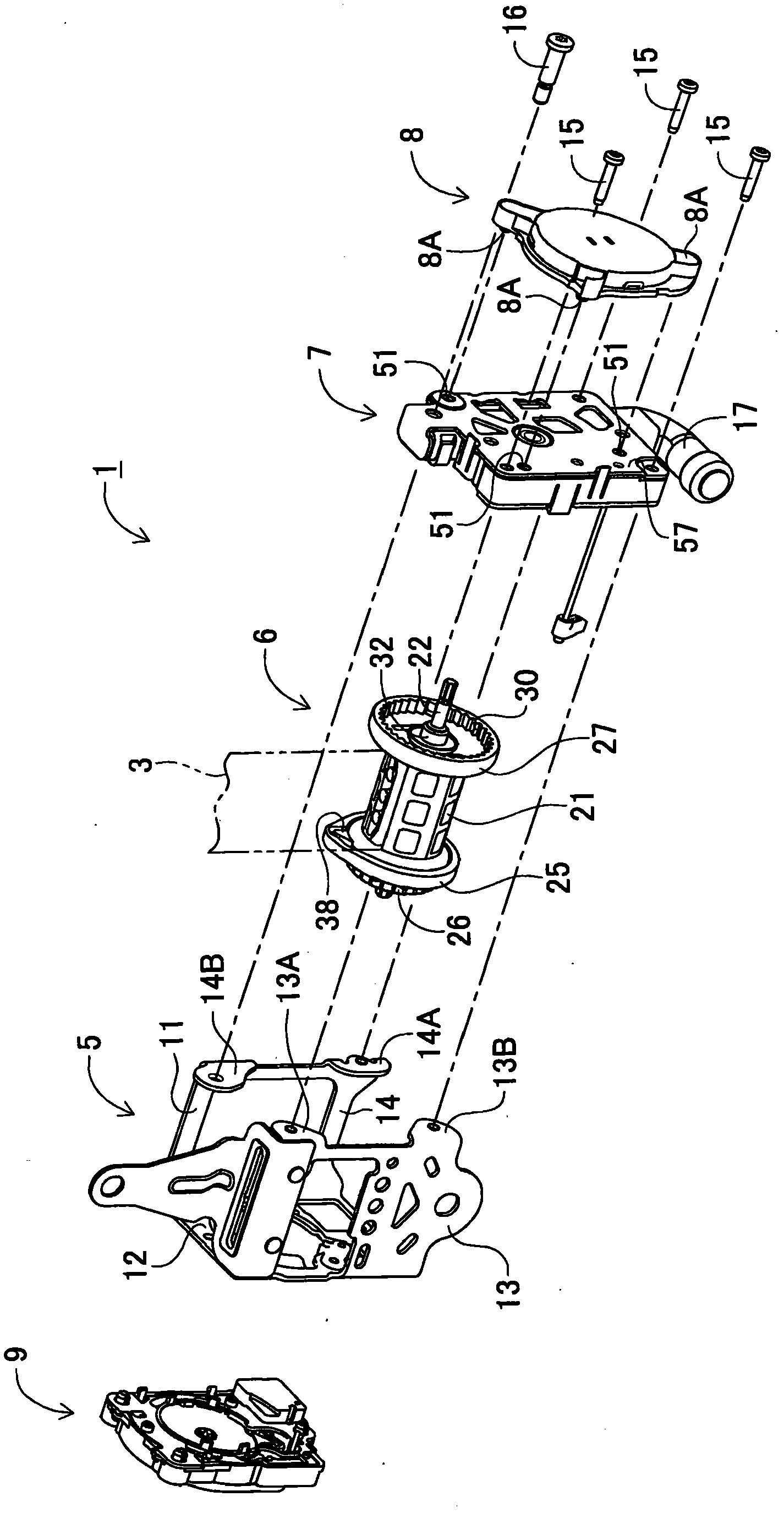

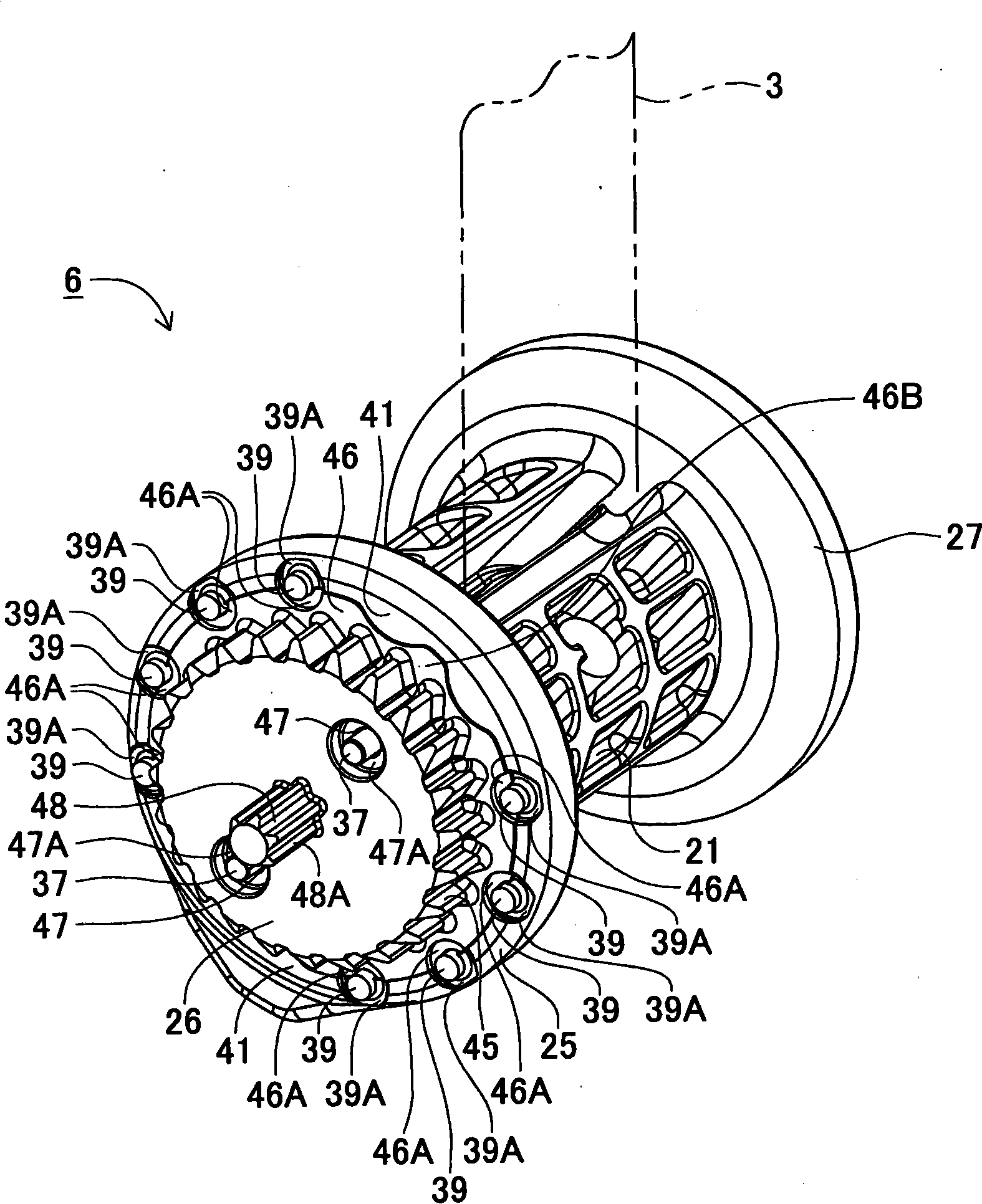

[0066] First, based on figure 1 and figure 2 A schematic structure of the seat belt retractor 1 according to the present embodiment will be described.

[0067] figure 1 It is a perspective view showing the appearance of the seat belt retractor according to this embodiment. figure 2 It is a perspective view showing each component of the seat belt retractor 1 in a disassembled state.

[0068] like figure 1 and figure 2 As shown, the seat belt retractor 1 is a device for retracting a vehicle webbing 3 . The seat belt retractor 1 is composed of a housing unit 5 , a take-up drum unit 6 , a pretensioner unit 7 , a take-up spring unit 8 and a lock unit 9 .

[0069] The locking unit 9 is fixed to a side wall portion 12 of a housing 11 constituting a housing unit 5 to be described l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com