Motor stator coil winding former

A technology of motor stator and winding die, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., and can solve problems such as difficult coil winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

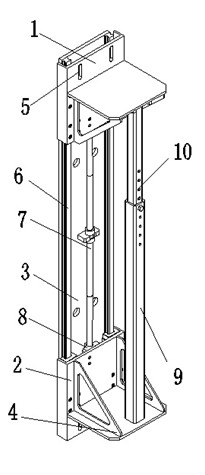

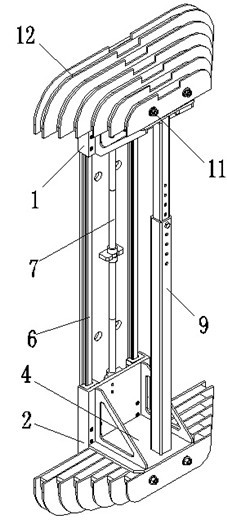

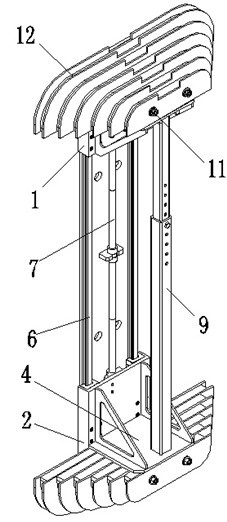

[0011] figure 1 Shown is a motor stator coil winding die, a motor stator coil winding die, including an upper slide base 1, a lower base 2, a double-ended screw 7, a bottom plate 3, a guide rail 6, a triangular support frame 4 and a winding Line template 12 parts. There are two guide rails 6, which are respectively arranged on both sides of the long side of the base plate 3; the upper slide base 1 and the lower slide base 2 are installed on the upper and lower ends of the guide rail 6 respectively, and can slide up and down along the guide rail 6; the upper slide base 1 and the slide base 2 Nuts 8 are respectively provided on the sliding base 2, the nuts 8 of the upper sliding base 1 and the lower sliding base 2 are internally rotated with a double-ended screw 7, and the upper sliding base 1 and the lower sliding base 2 move up and down along the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com