Water detection type guide rail bottle straightening machine for beer bottles

A beer bottle and bottle unscrambler technology, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as low efficiency, high production costs, and harsh working environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

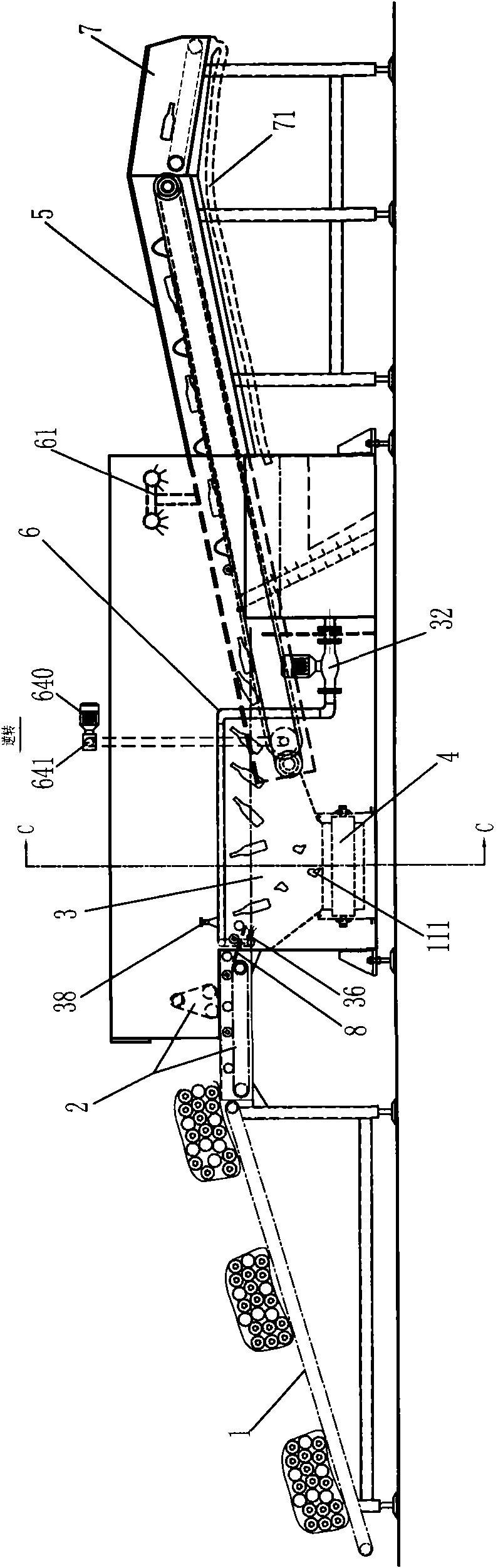

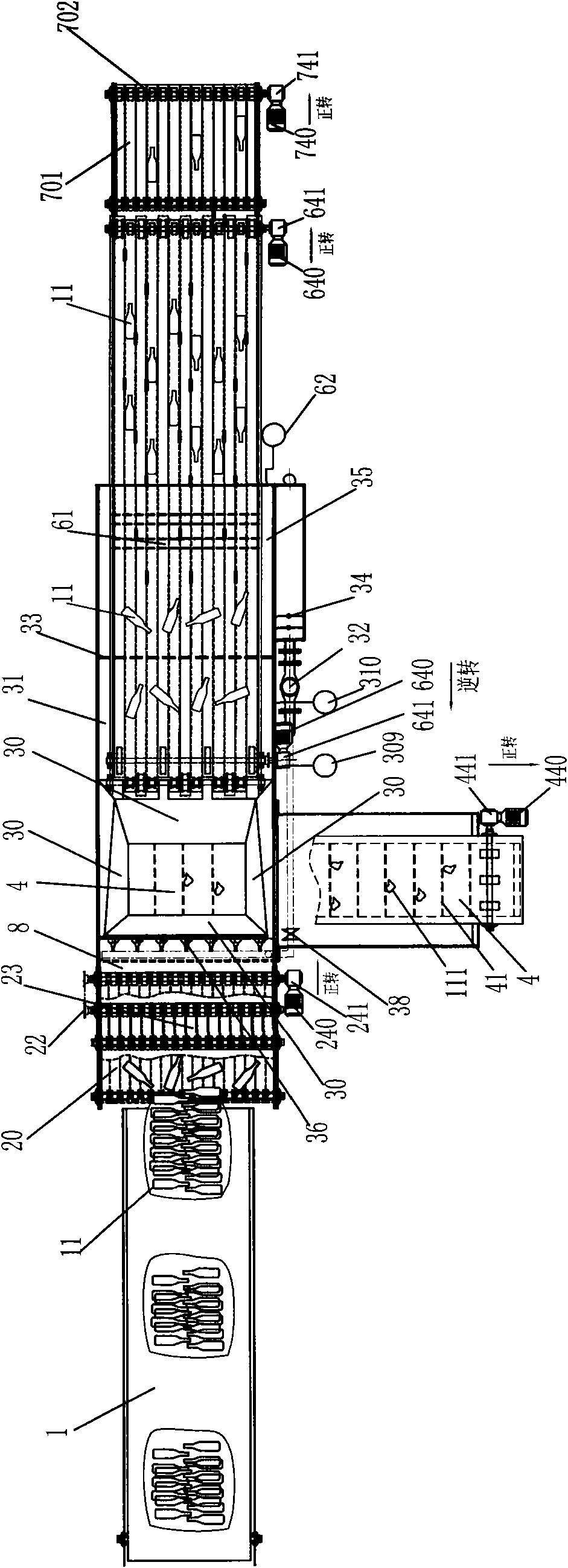

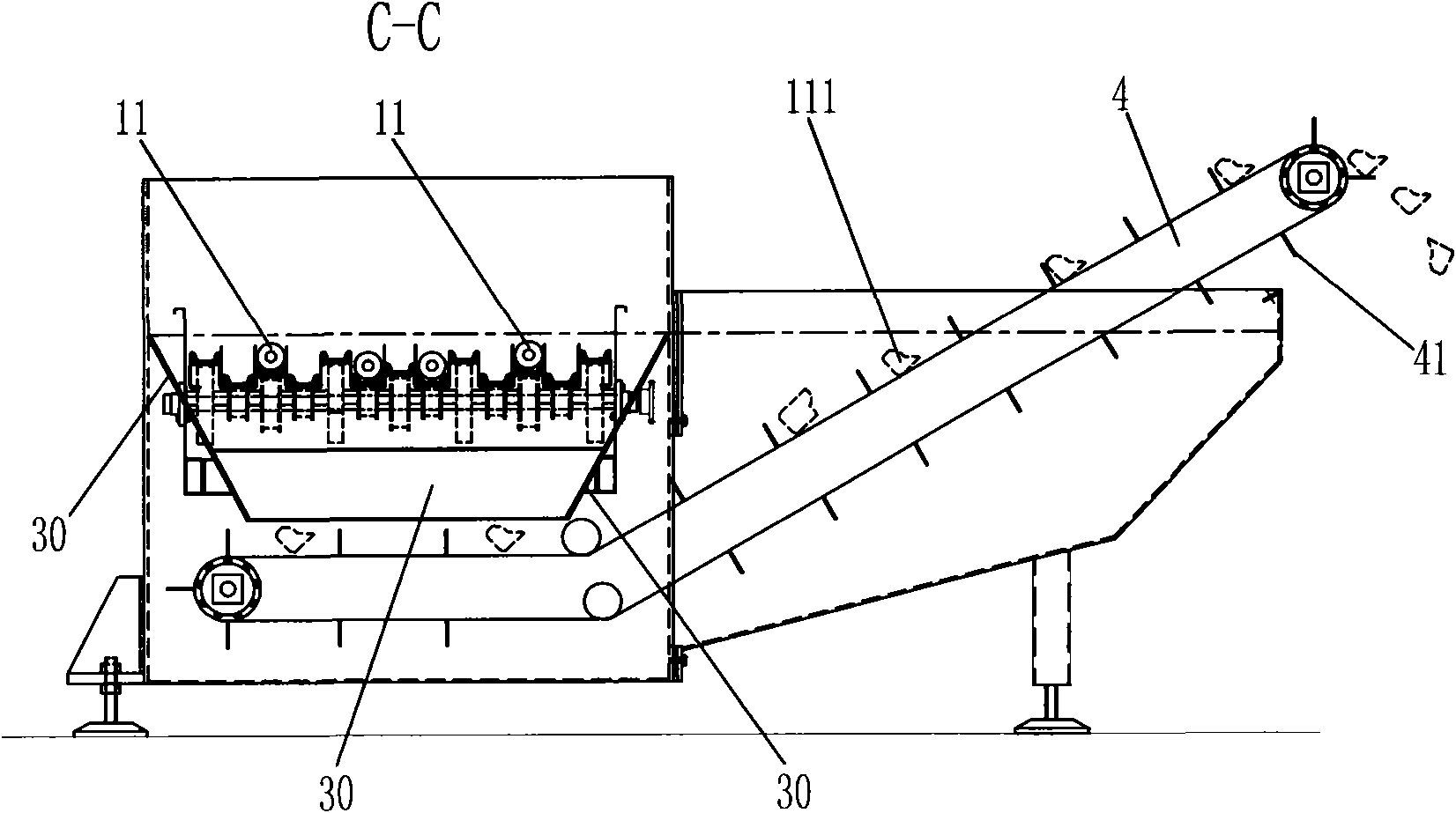

[0016] see figure 1 As shown, the main structure of the present invention includes a glass bottle lifting conveyor belt 1 for conveying sacks, a non-slip conveyor belt 2 for bottle quantification and equalization, a hydraulic bottle conveying circulating water tank 3, a broken bottle sediment removal scraper lifting conveyor belt 4, a bottle positioning transmission guide rail 5, Jet circulating water pipe 6 and downhill pouring conveyor belt 7.

[0017] The sack glass bottle lifting conveyor belt 1 is an uphill conveyor belt, and the sack glass bottle includes glass bottles 11 and broken bottles 111. Broken bottle 111 is sorted by buoyancy, and the broken bottle sediment removal scraper 41 lifting conveyer belt 4 that sinks into the bottom of the circulating water tank is removed.

[0018] see figure 2 As shown in FIG. 4 , the non-slip conveyer be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com