Bolt loading ring-block type corrosive wear testing machine

A corrosion and wear test, loading ring technology, applied in the direction of weather resistance/light resistance/corrosion resistance, wear resistance test, measurement device, etc. Problems such as friction coefficient cannot be obtained to achieve the effect of improving accuracy, reducing thermal impact and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the specific embodiment of the invention is not limited thereto.

[0025] Such as figure 1 , figure 2 As shown, a bolt loading ring block type corrosion and wear testing machine is composed of a bolt loading system, a friction measurement system, a transmission system and a crucible resistance furnace system. The frame is composed of four columns 1, a main frame supporting platform 8, three crossbeams 2 fixedly connected with the columns 1 for reinforcement, and a horizontal support base plate 28 to form a frame structure below the frame.

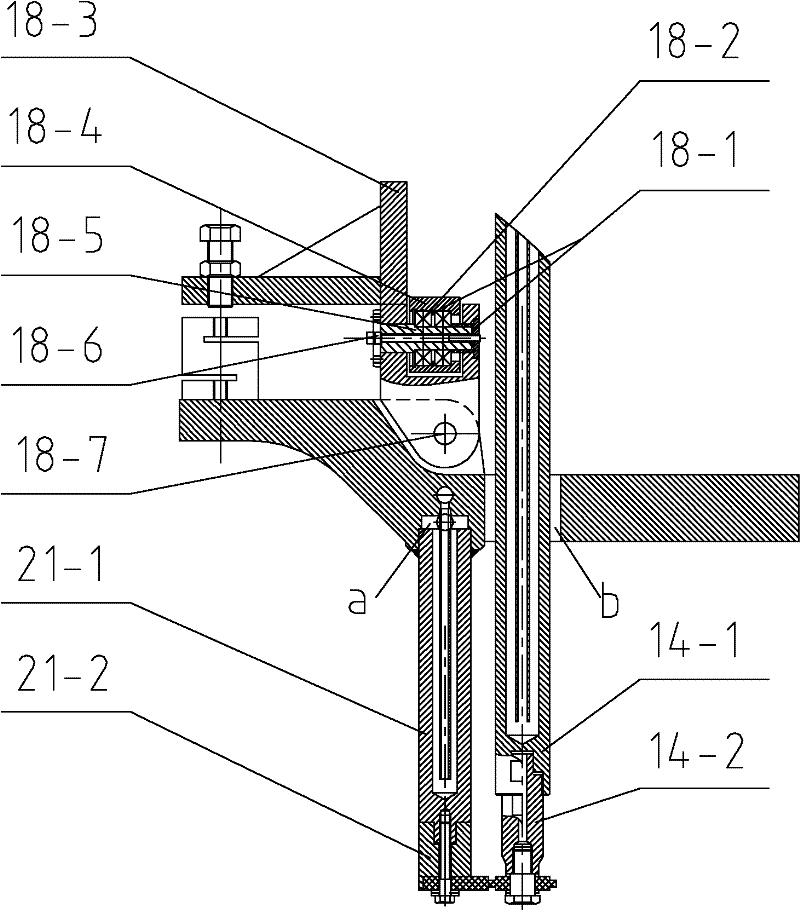

[0026] Such as figure 1 As shown, the bolt loading system includes a loading bolt 15, a lock nut 16, a load cell 17, a suspension bearing connection assembly 18, a positive pressure loading main force hinge seat 20, and a loading rod 21. Their installation and connection relations are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com