Mechanical continuous mining method for gently inclined thin ore body

A mining method and thin ore body technology, which is applied in the field of mechanized continuous mining of underground mines, can solve the problems of high production material consumption, low resource utilization, poor production safety, etc., achieve high production efficiency, solve mining problems, and ore loss low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

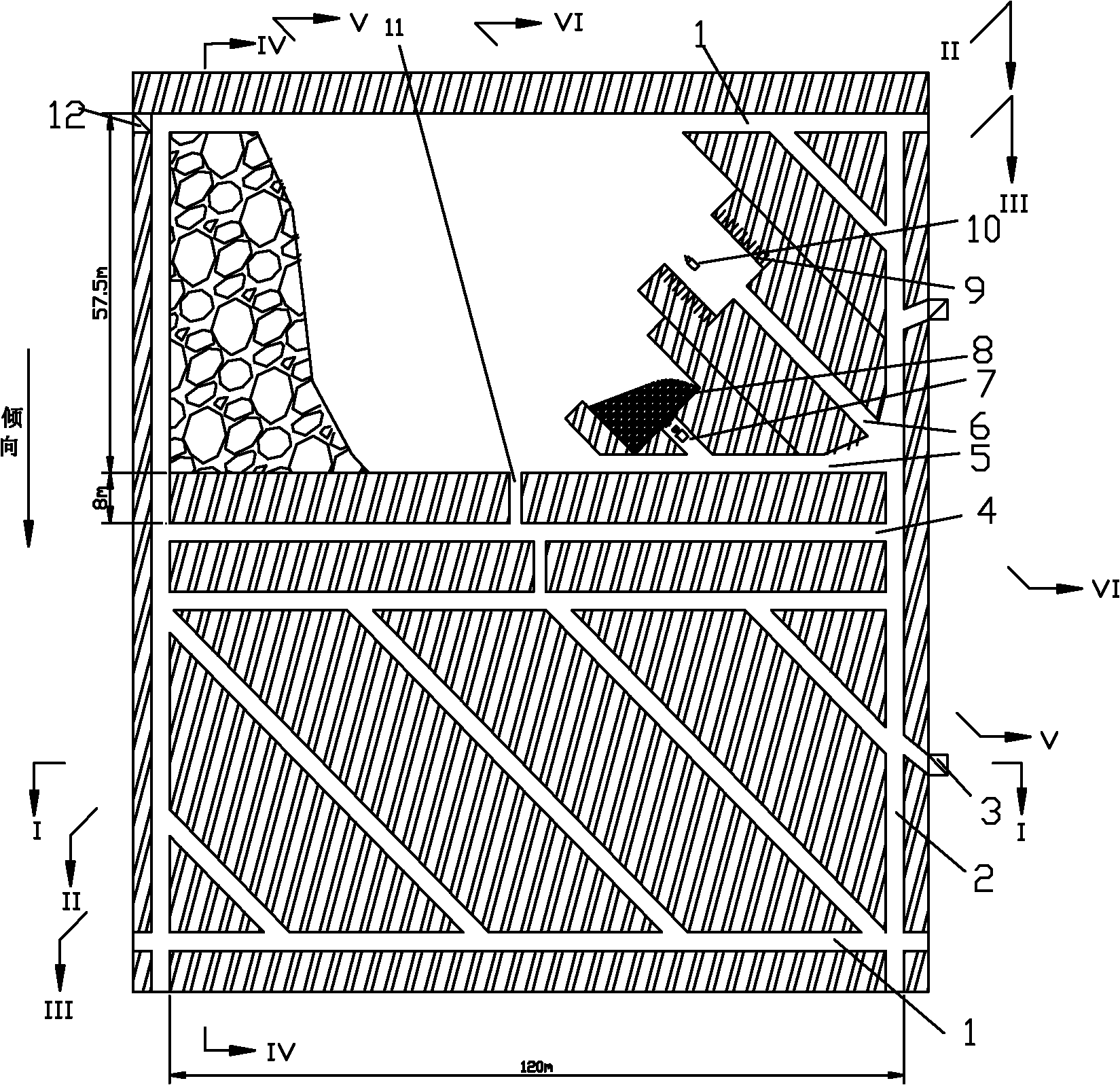

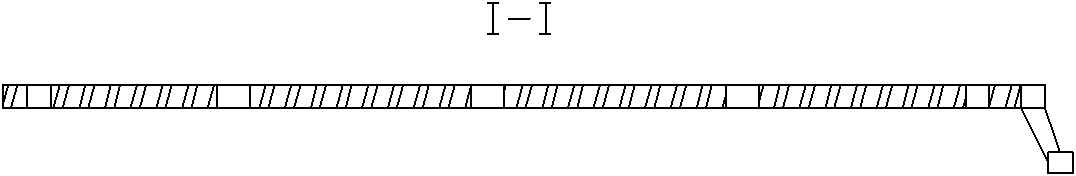

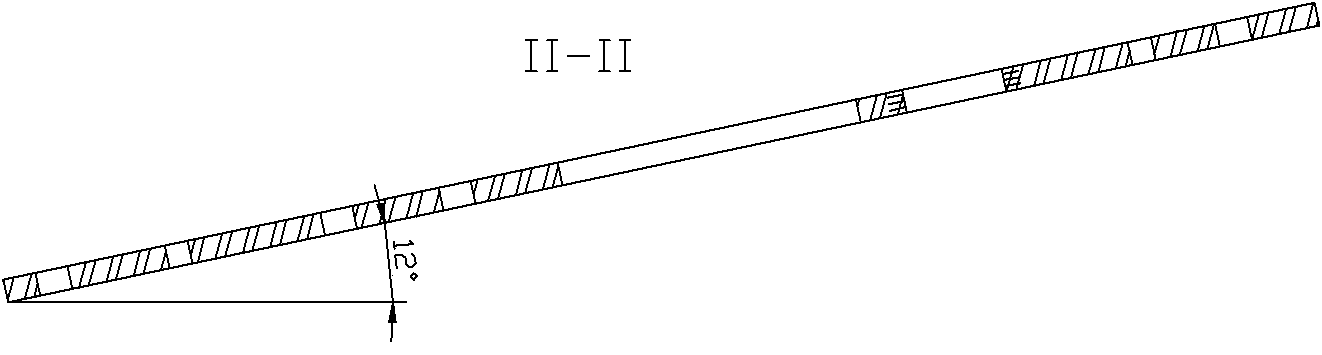

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 , in the forward and backward mining design drawings, a main uphill roadway 2 is arranged every 120m along the ore body, and the ore body is divided into 120m wide ore blocks. The mine room is arranged along the inclined direction, and the length of the mine room is The width is 120m, and the width is 57.5m. Two continuous ore pillars with a width of 8m are left in the mine room with a distance of 3m. The angle direction of 45° is divided into 5 stopes, each stope is 23m wide, and the rock drilling roadway 6 is arranged obliquely, which can reduce the inclination angle of the roadway and reduce the load of the scraper; , connected to the upper horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com