Nanocrystallization compound-type biological liquid fertilizer and production method thereof

A bio-fertilizer and nanotechnology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of product validity period affecting the survival rate of microorganisms, and achieve the effects of prolonging the product validity period, promoting growth, restoring growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

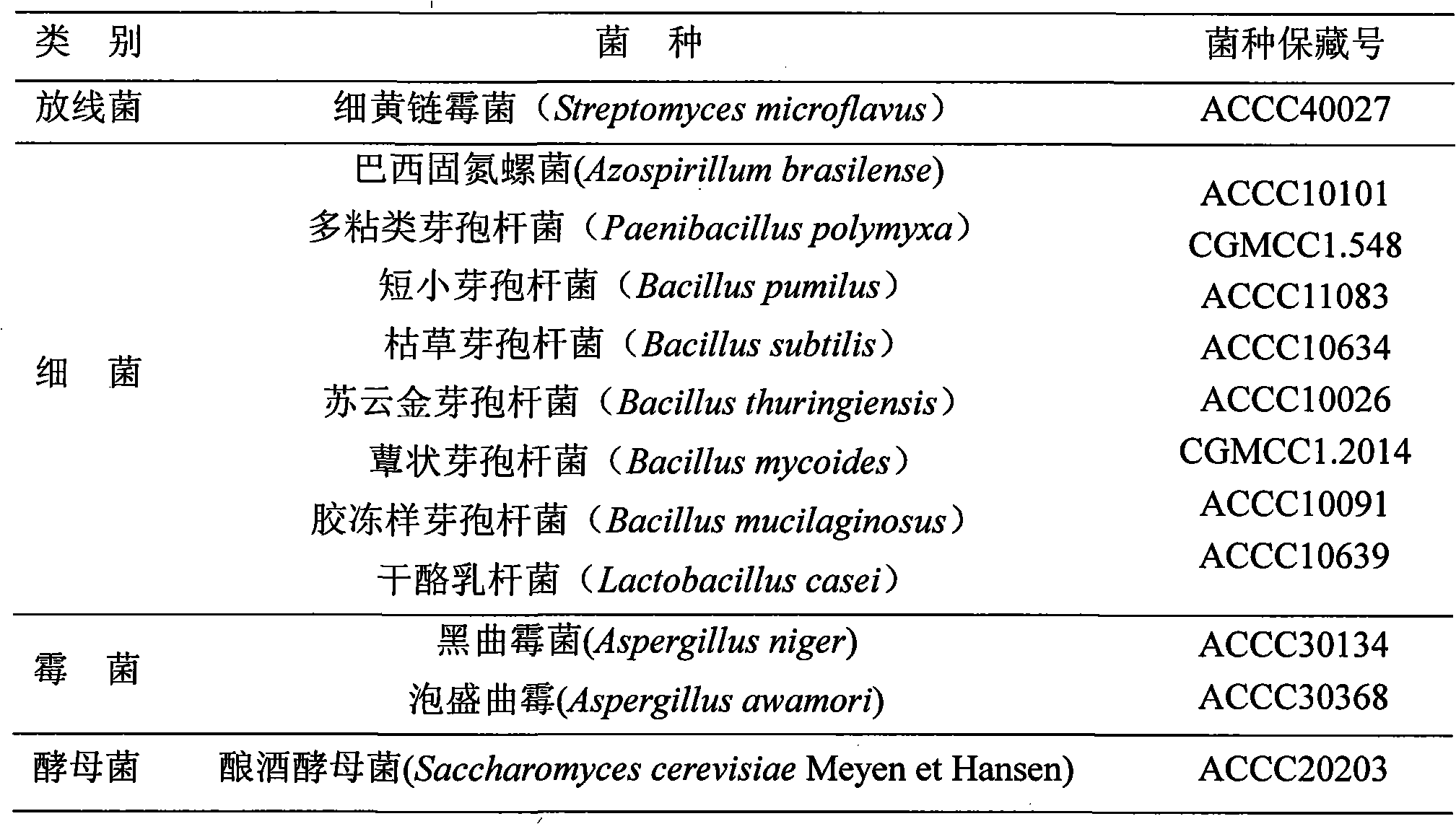

Method used

Image

Examples

Embodiment 1

[0025] 1. Taking the product volume as 1L as an example, mix inorganic nutrients with nano-sized water, then add organic nutrients and nano-sized aloe juice in turn to make mixture A. The components and contents used are shown in Table 2.

[0026] Table 2

[0027]

[0028] Component Content

[0029]

[0030] Nano Aloe Juice 0.05ml / L

[0031] Seaweed 0.005g / ml

[0032] Amino acid 0.002475g / ml

[0033] Ca(NO 3 ) 2 0.125g / ml

[0034] KNO 3 0.18g / ml

[0035] K H 2 PO 4 0.24g / ml

[0036] MgSO 4 0.05g / ml

[0037] BO 0.049g / ml

[0038] Fe 0.004g / ml

[0039] MnSO 4 0.002g / ml

[0040] Zn 0.0036g / ml

[0041] Mo 0.0007g / ml

[0042] Co 0.002g / ml

[0043] Nano water balance

[0044]

[0045] 2. Use the aforementioned microbial strains to ...

Embodiment 2

[0047] 1. Taking the product volume as 1L as an example, mix inorganic nutrients with nano-sized water, then add organic nutrients and nano-sized aloe juice in turn to make mixture A. The contents of each component used are shown in Table 3.

[0048] table 3

[0049]

[0050] Component Content

[0051]

[0052] Nano Aloe Juice 0.05ml / L

[0053] Seaweed 0.005g / ml

[0054] Amino acid 0.002475g / ml

[0055] Ca(NO 3 ) 2 0.25g / ml

[0056] KNO 3 0.045g / ml

[0057] K H 2 PO 4 0.55g / ml

[0058] MgSO 4 0.05g / ml

[0059] BO 0.0225g / ml

[0060] Fe 0.005g / ml

[0061] MnSO 4 0.00225g / ml

[0062] Zn 0.0037g / ml

[0063] Mo 0.00075g / ml

[0064] Co 0.002g / ml

[0065] Nano water balance

[0066]

[0067] 2. Use the aforementioned microbial strain...

Embodiment 3

[0069] 1. Taking the product volume as 1L as an example, mix inorganic nutrients with nano-sized water, then add organic nutrients and nano-sized aloe juice in turn to make mixture A. The contents of each component are shown in Table 4.

[0070] Table 4

[0071]

[0072] Component Content

[0073]

[0074] Nano Aloe Juice 0.05ml / L

[0075] Seaweed 0.005g / ml

[0076] Amino acid 0.002475g / ml

[0077] KNO 3 0.2g / ml

[0078] MgSO 4 0.05g / ml

[0079] BO 0.05g / ml

[0080] Co 0.006g / ml

[0081] Nano water balance

[0082]

[0083] 2. Use the aforementioned microbial strains to ferment (expanded culture), and the culture medium for the expanded culture is a mixture of conventional culture, nano-sized aloe juice and nano-sized water. The total number of microorganisms after fermentation is 2.2×10 9 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com