Anti-leakage two-way air braking system for variable-frequency speed-regulating industrial and mineral electric locomotive

A mining electric locomotive, frequency conversion speed regulation technology, applied in the direction of brakes, brake components, brake transmission devices, etc., can solve the problem of inability to move, achieve the effect of flexible braking and avoid wheel locking and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

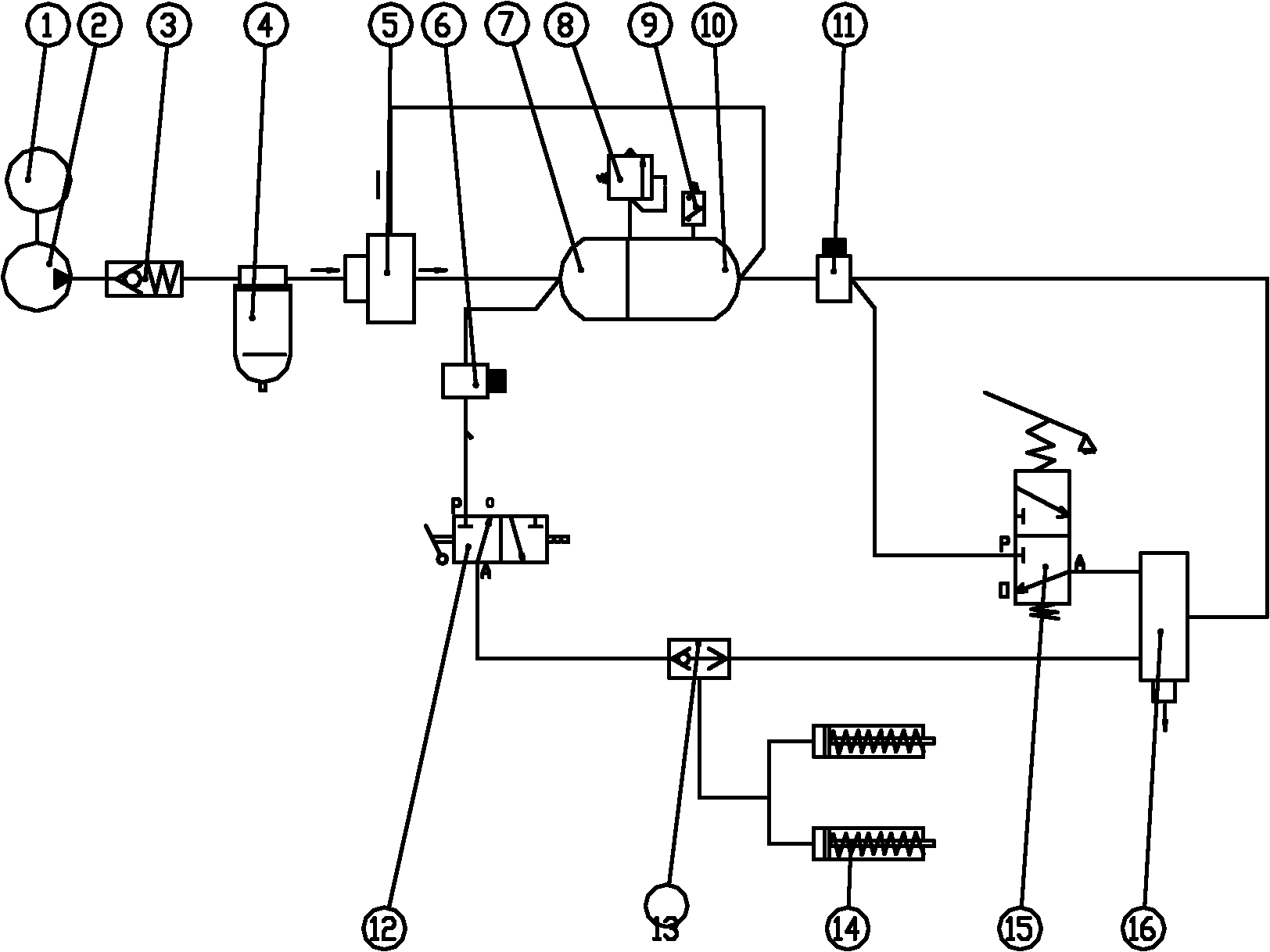

[0008] see figure 1 , the present invention includes an air compressor motor 1, an air compressor 2, a one-way valve 3, an oil-water separator 4, a four-circuit protection valve 5, a first pressure regulating valve 6, a first air storage cylinder 7, a safety valve 8, an air pressure Relay 9, second air storage cylinder 10, second pressure regulating valve 11, hand brake valve 12, shuttle valve 13, booster type brake cylinder 14, pedal brake valve 15 and relay valve 16.

[0009] The working principle of the present invention is: the air compressor motor 1 drives the air compressor 2 to work, the compressed air passes through the one-way valve 3 and the oil-water separator 4 for automatic drainage, and then passes through the four-circuit protection valve 5 to the first air storage cylinder 7 and the first air storage cylinder 7. Two air storage cylinders 10 are inflated, and when the air pressure of the first air storage cylinder 7 or the second air storage cylinder 10 reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com