Graded sand taking and conveying system used for tailing reuse of tailing pond

A technology of sand conveying and tailings pond, applied in the field of graded sand extraction conveying system, can solve the problems of inability to meet the needs of large-scale production, inability to continuously supply materials, complicated operation process, etc., to solve the problem of poor sand return and reduce equipment loss , to avoid the effect of settlement dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

[0020] In order to further describe the present invention, the following is a further detailed description of a graded sand extraction conveying system for tailings reuse in tailings ponds according to the present invention in conjunction with the accompanying drawings and embodiments.

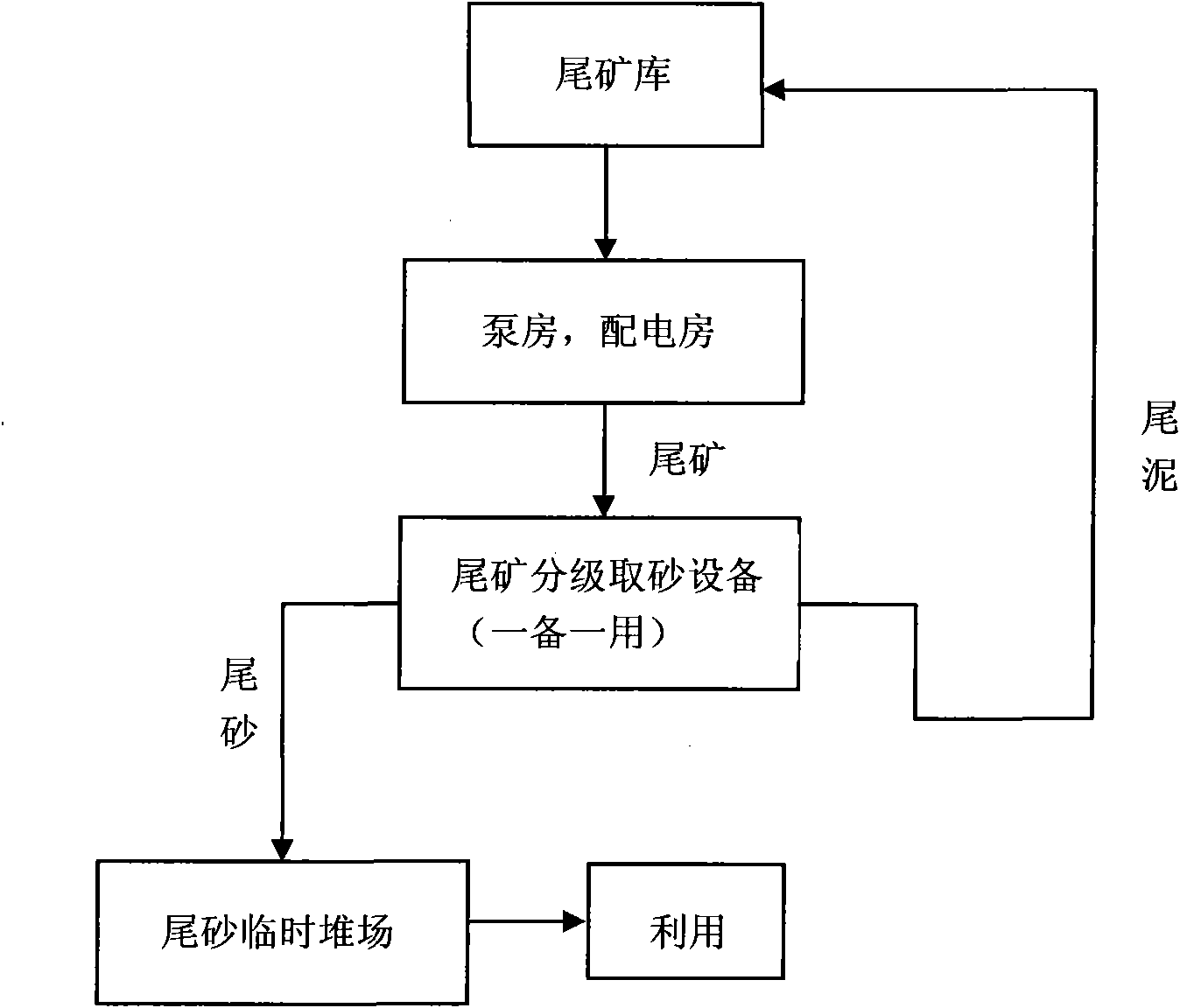

[0021] Depend on figure 1 Shown is a structural schematic diagram of a graded sand-taking conveying system for tailings pond tailings reuse in the present invention and combined with figure 2 , image 3 It can be seen that in practical application, the tailings in the tailings pond are fed into the tailings classification and sand removal equipment through the sand pump and the tailings conveying pipe - the feed port of the special spiral classifier for tailings classification and sand removal. , the sand is classified and taken by the spiral classifier, and the tailings (that is, the coarse-grained part, accounting for about 80% of the tailings) is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com