Coupling for coupling a vacuum hose to a central vacuum source

A technology for vacuum hoses and connectors, applied in the direction of suction hoses, vacuum cleaners, applications, etc., can solve the problems of complex and expensive manufacturing, and achieve the effect of low-cost structure, the lowest loss of suction, and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

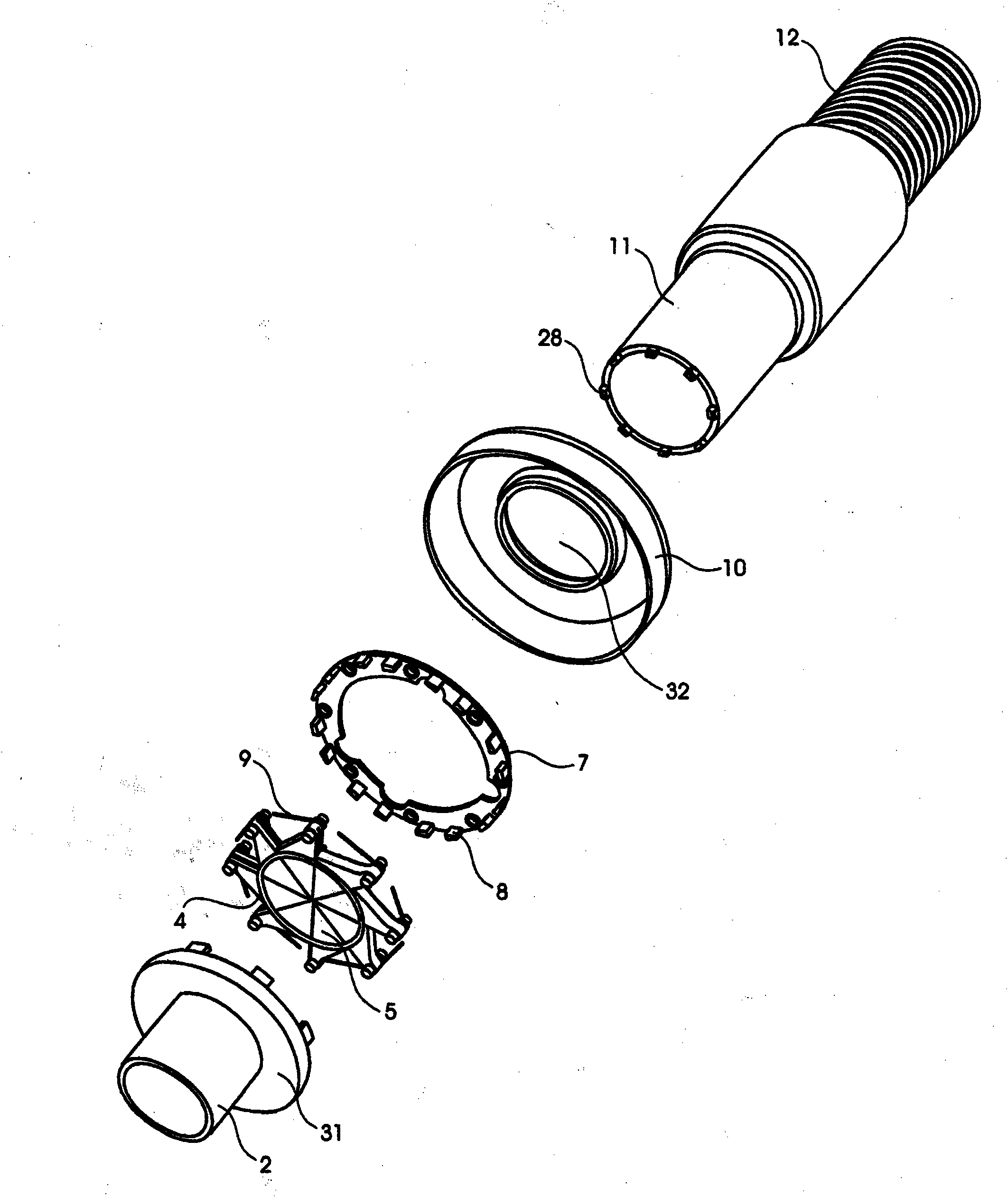

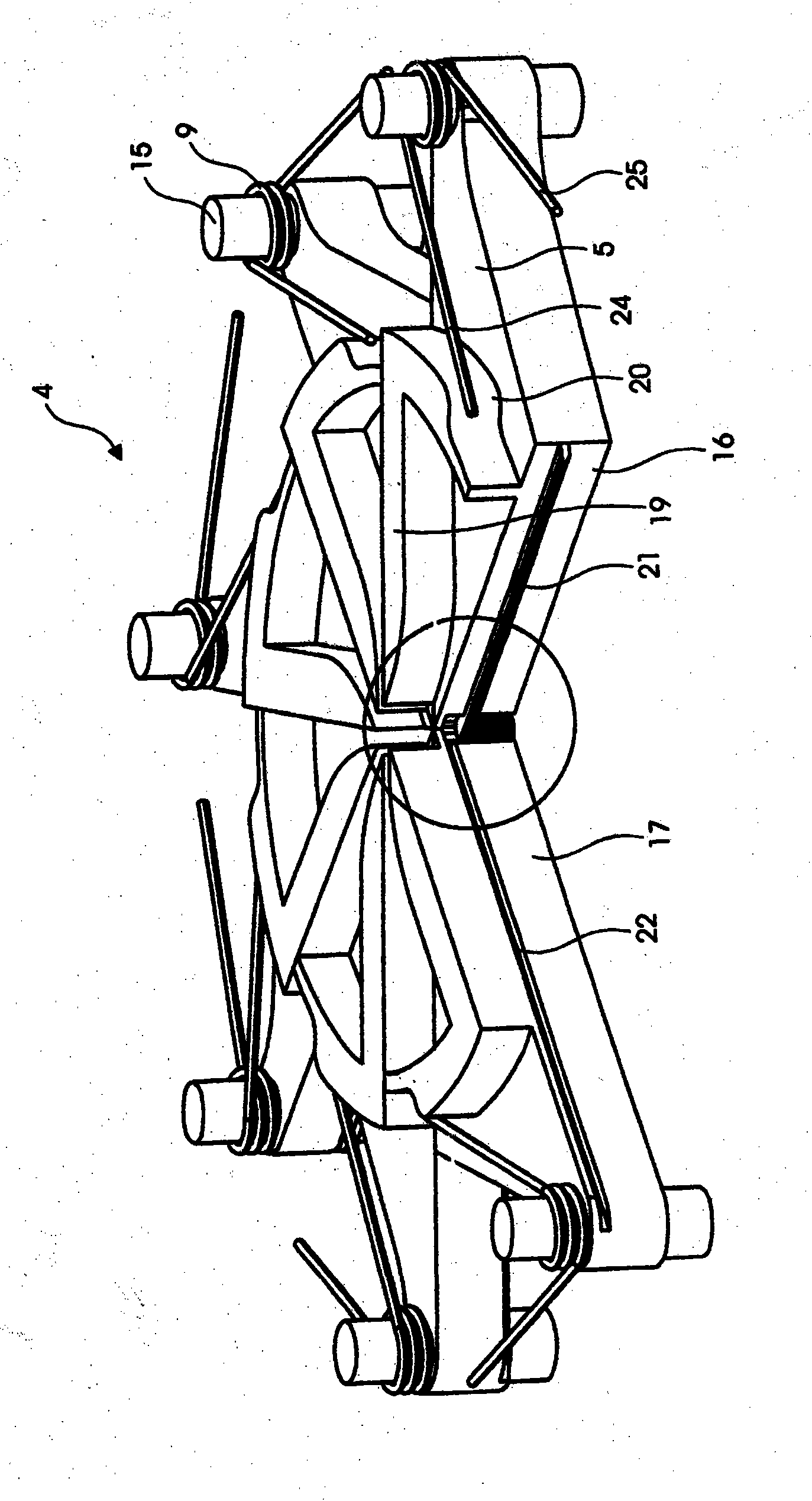

[0043] The connector of the invention shown in the figures is as an example intended for use in connecting a flexible vacuum hose with a nozzle used in a building for vacuum cleaning areas to a central vacuum placed behind a partition in a building such as a wall source. figure 1 Shown in the exploded view, the connector 1 includes: through the partition wall 3 ( figure 1 not shown) an extended tube head 2, in this example a valve 4 with 8 pivotally placed valve parts 5 to open and close a port 6 in the tube head, a seat ring 7 with a seat 8, For restoring the spring 9 ( figure 1 not shown), a cup 10 for covering the valve, and a tubular adapter 11 attached to a flexible vacuum hose 12 and fitted into a port in the tube head.

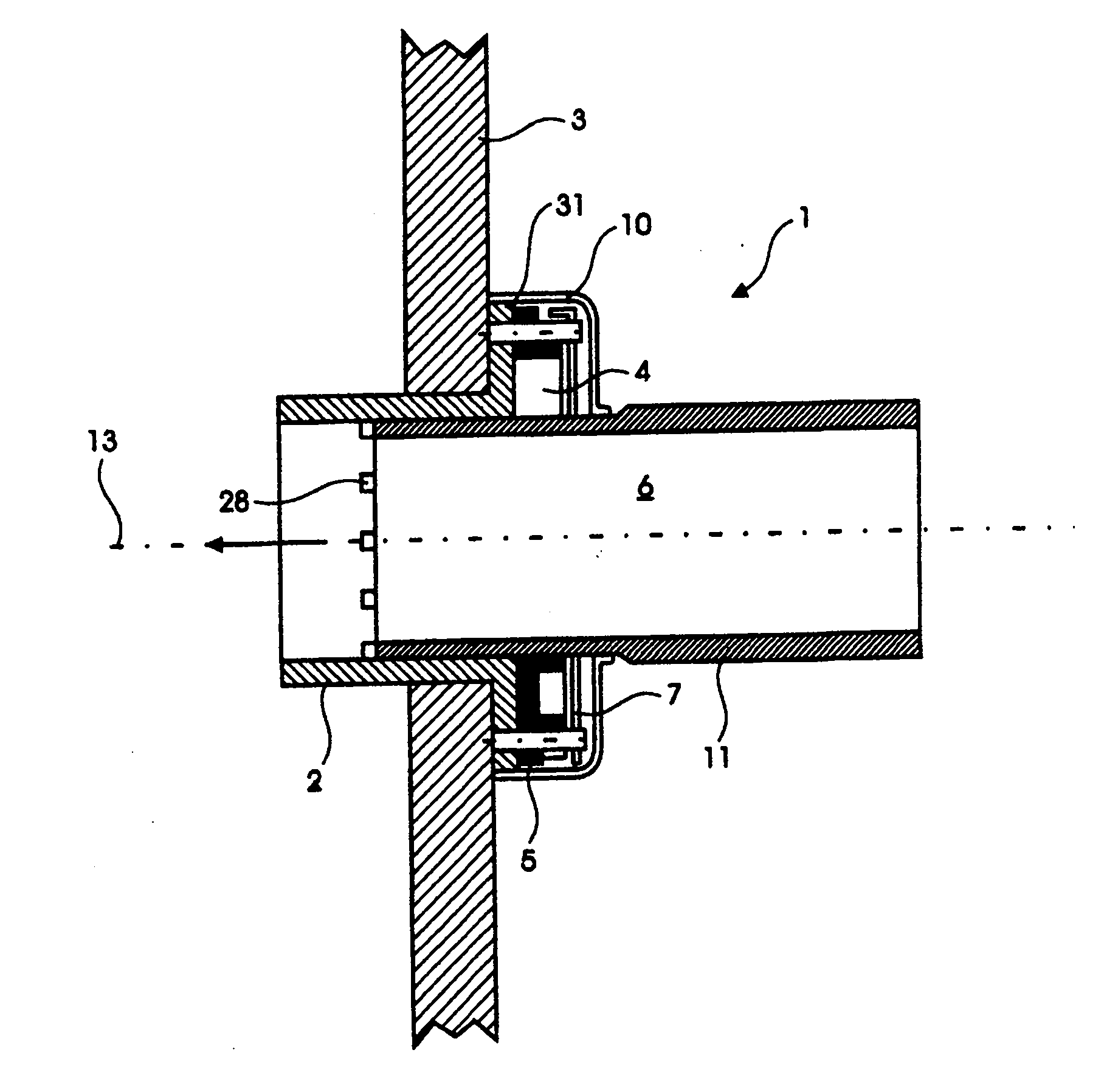

[0044] figure 2 shows an axial cross-section of the connector 1 in the installed state, with the head 2 passing through the partition wall 3 , the valve 4 is opened and the adapter 11 is pressed axially into the port of the head 2 through the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com