Improved ash-collecting device at furnace mouth of enamelling machine furnace

An enamelling machine and oven technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problem of sticking to the wire or falling into the paint vat, the corner of the L-shaped baffle is not easy to clean, and affects the production quality of the enameled wire, etc. problem, to achieve the effect of reliable and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

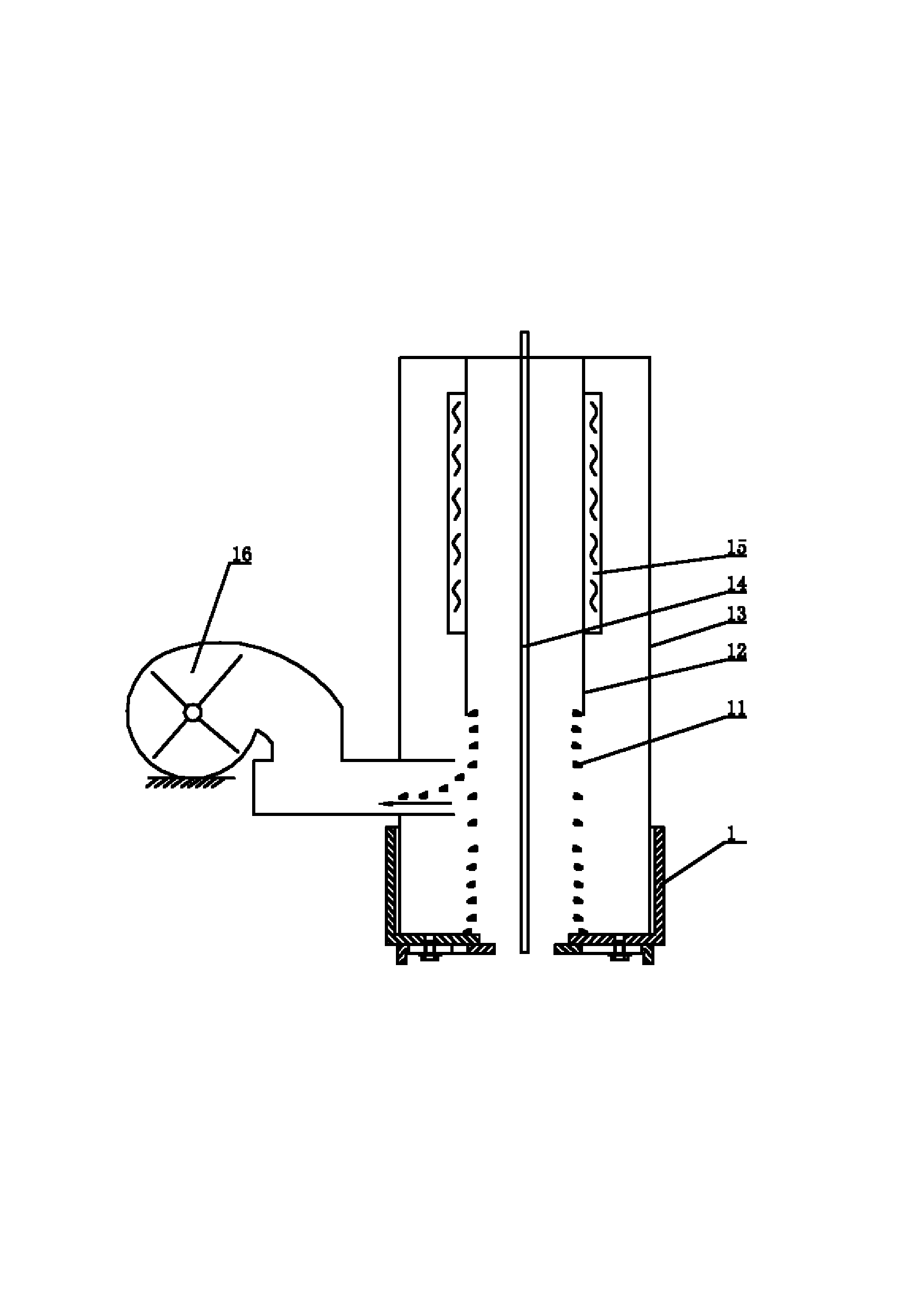

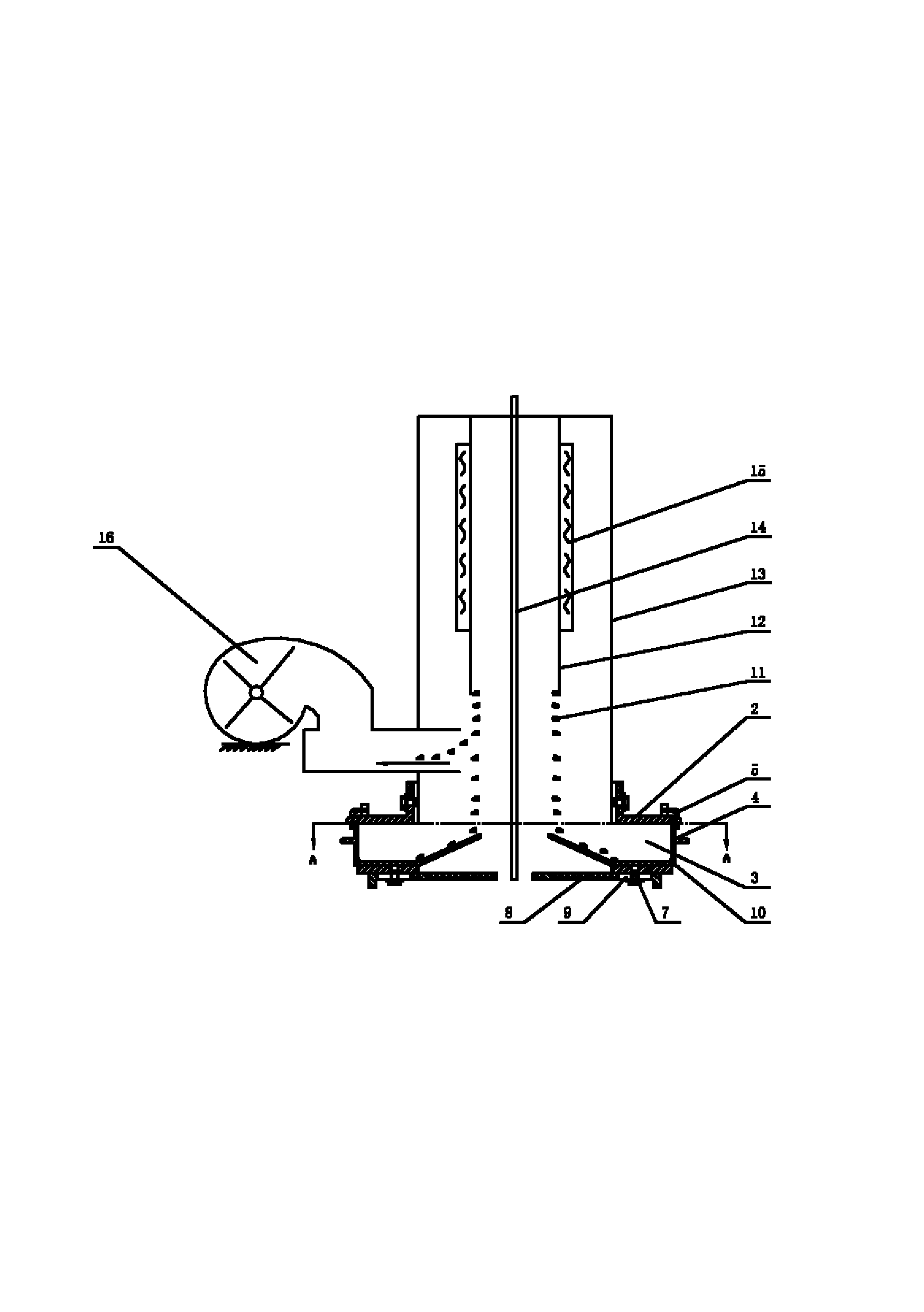

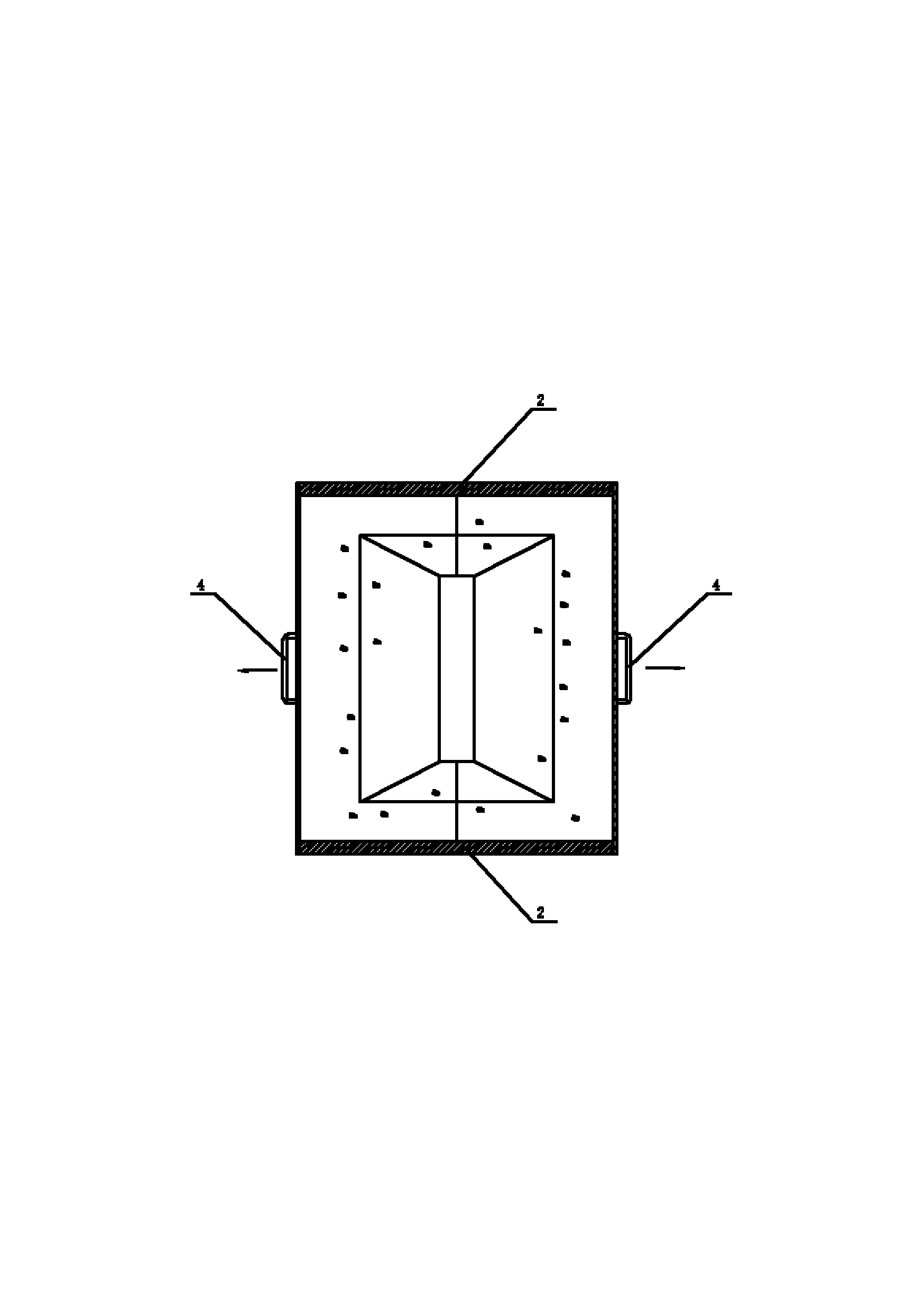

[0010] See figure 2 and image 3 , the ash-connecting device of the oven mouth of the enamelling machine of the present invention comprises a bracket, and the bracket is installed on the oven mouth of the enamelling machine. Gray box 4, the gray box 4 that receives paint is locked with square support 2 by lock catch 5. The bottom plate of the paint receiving box 4 is connected with an inclined baffle 6; the side wall of the paint receiving box 4 is connected with the arc 10 of the bottom plate for transition; the square bracket 2 matches the shape of the oven mouth of the enamelling machine; the lower part of the square bracket 2 is installed through a nut 7 There is a windshield 8; the windshield 8 is provided with a keyway 9, and the windshield 8 can slide in the keyway 9 to control the size of the air inlet.

[0011] The working process of the present invention will be specifically described below in conjunction with the accompanying drawings: during enameled wire produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com