Temperature regulating device for photovoltaic polycrystalline silicon ingot casting furnace

A technology of polycrystalline silicon ingot furnace and temperature control device, which is applied in the direction of polycrystalline material growth, crystal growth, temperature control, etc., can solve the problem of unsatisfactory temperature control effect of open-loop temperature control, the same difficulty in operation time and operation process, and no solution. Considering the differences in the operating time of polysilicon ingot furnaces, the effect of improving the quality of polysilicon ingots, stable measurement performance and not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

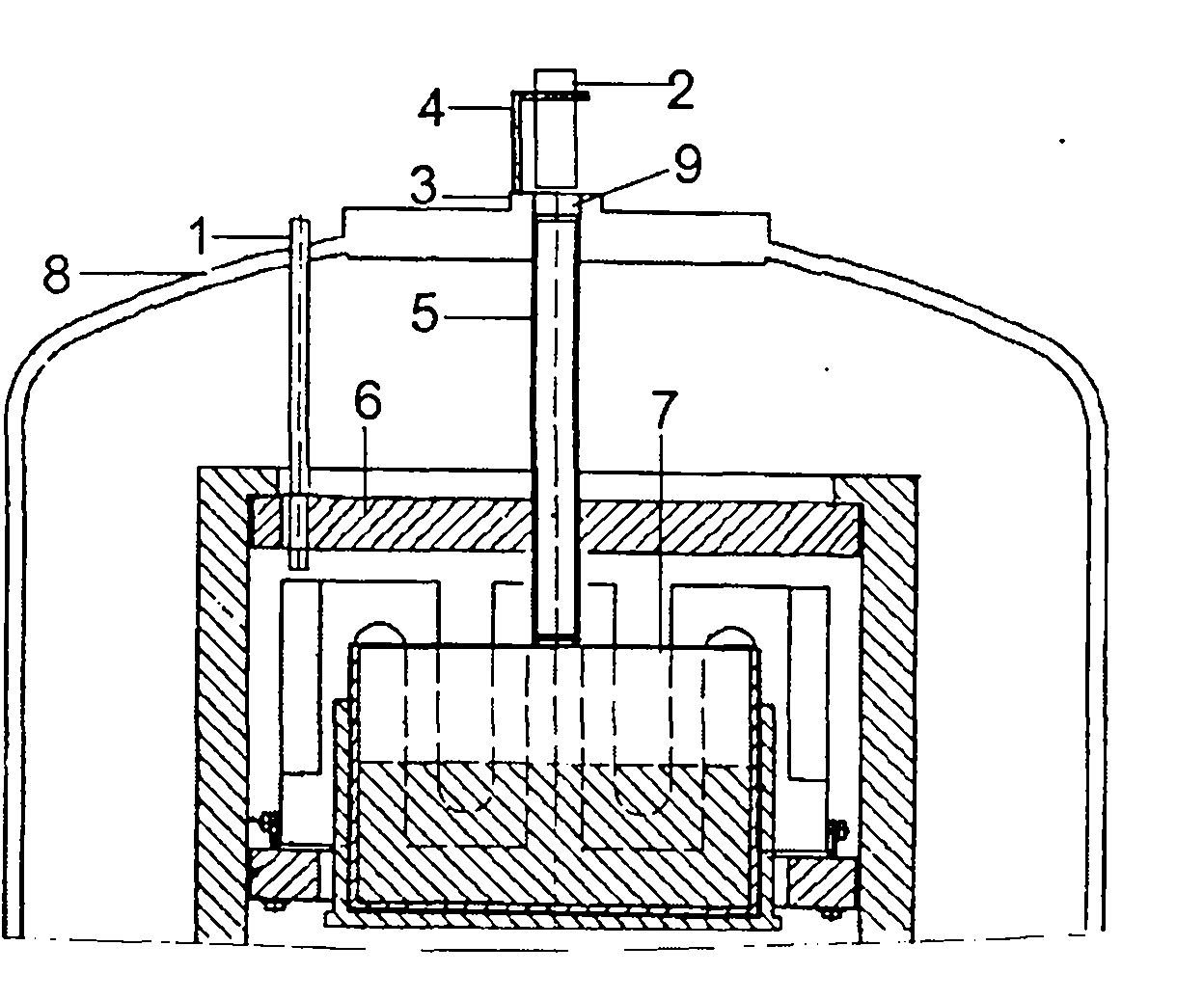

[0015] The temperature control device of the photovoltaic polycrystalline silicon ingot furnace proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments:

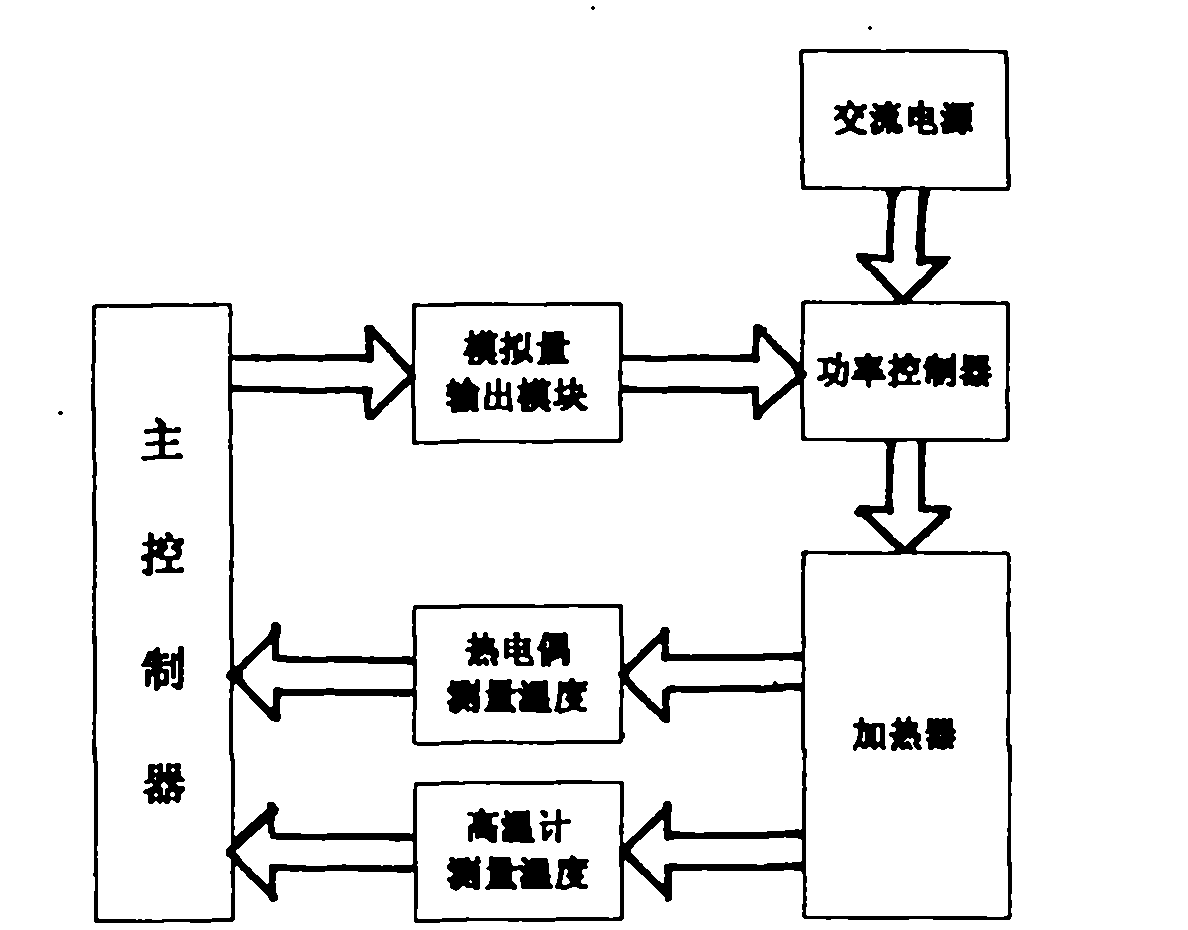

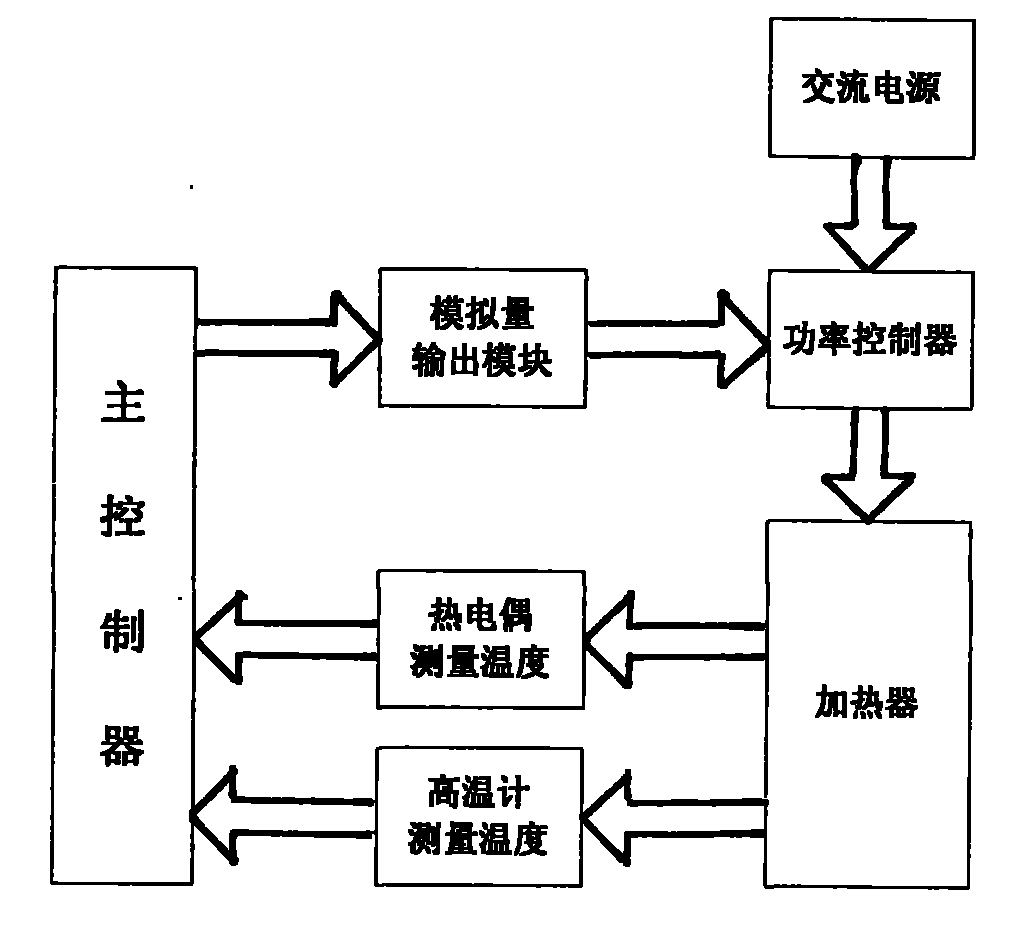

[0016] The structure of the temperature control device of the photovoltaic polysilicon ingot furnace of the present invention is as follows: figure 1 shown.

[0017] The device includes a temperature control thermocouple installed on a photovoltaic polysilicon ingot furnace, and is characterized in that it also includes an optical pyrometer on the photovoltaic polysilicon ingot furnace, a main controller, an analog output module, a power controller and an AC power supply; Wherein, the temperature output ends of the temperature control thermocouple and the optical pyrometer are respectively connected with the input ends of the main controller, and the output ends of the main controller are connected with the input ends of the power controller through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com