Automobile front cover hinge

A hinge and front cover technology, which is applied to pin hinges, door/window fittings, hinge plates, etc., can solve the problems of large opening and closing force, unsmooth opening and closing of the front cover hinge, abnormal opening and closing friction noise, etc. To achieve the effect of solving the inflexibility of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the utility model is further described.

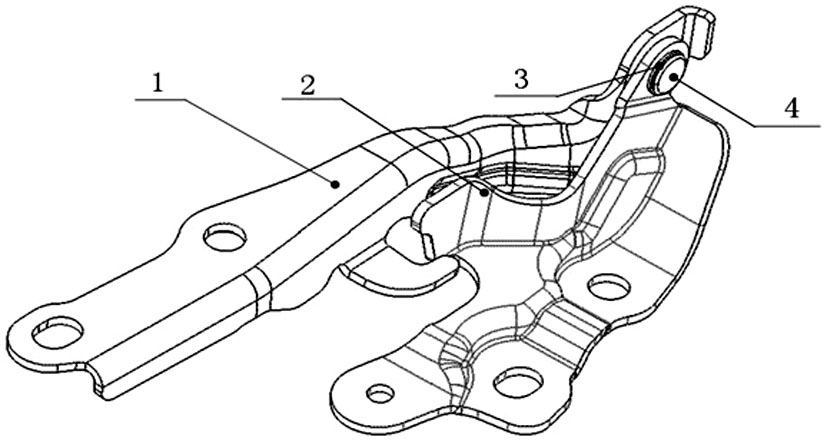

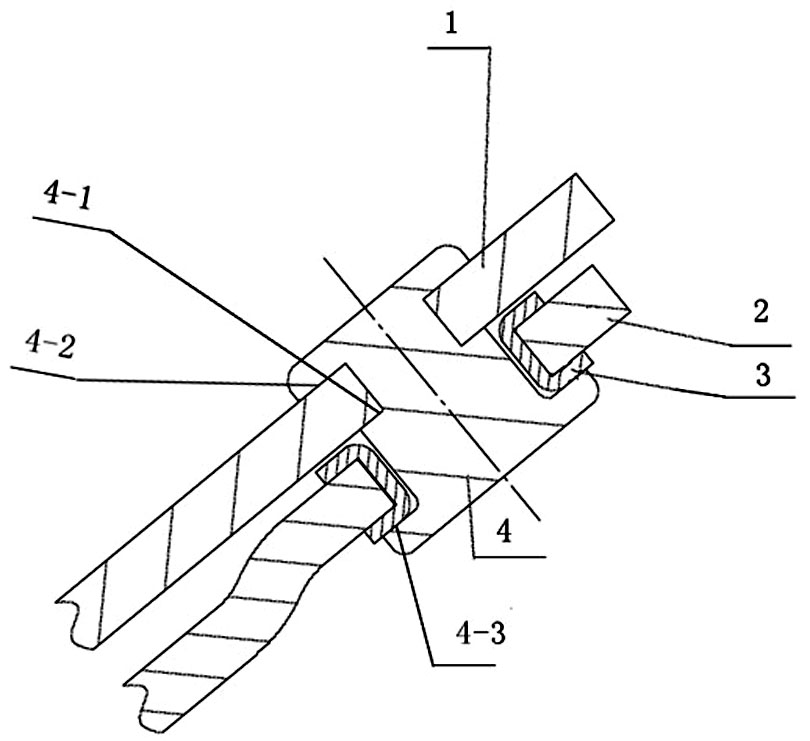

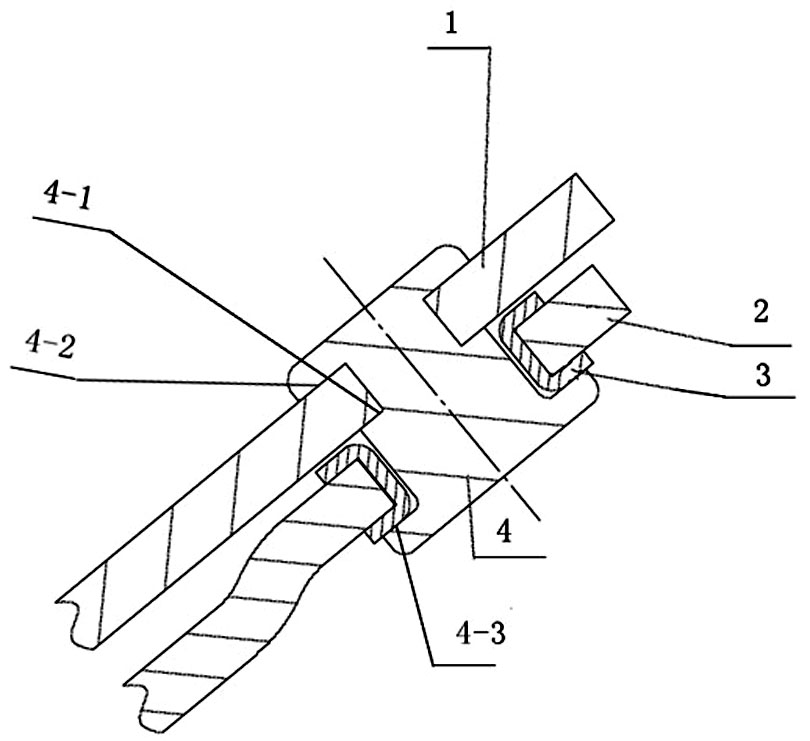

[0012] see figure 1 and figure 2 A kind of car front cover hinge shown, its rivet connecting male hinge 1 and female hinge 2 is a step rivet 4, and one section diameter of this step rivet is larger, and one section diameter is smaller; A self-lubricating bushing 3 is arranged on the female In the pin hole of the hinge 2, the stage with a larger diameter of the step rivet 4 cooperates with the self-lubricating bush 3, and the stage with a smaller diameter of the step rivet 4 cooperates with the pin hole of the male hinge 1.

[0013] The working surface of the self-lubricating bush has the following two functions. First, when the male hinge and the female hinge are in relative motion, the working surface of the self-lubricating bush is in contact with the male hinge, reducing the frictional resistance of the movement and preventing abnormal friction noise. . Second, when the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com