A two-wheel autonomous mobile welding device

A welding device and autonomous moving technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of restricting the application and development of mobile welding robot technology, uncontrollable posture of the table body, and poor ability to adapt to the environment. The wheel movement is flexible and smooth, the reliability of dead reckoning is improved, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

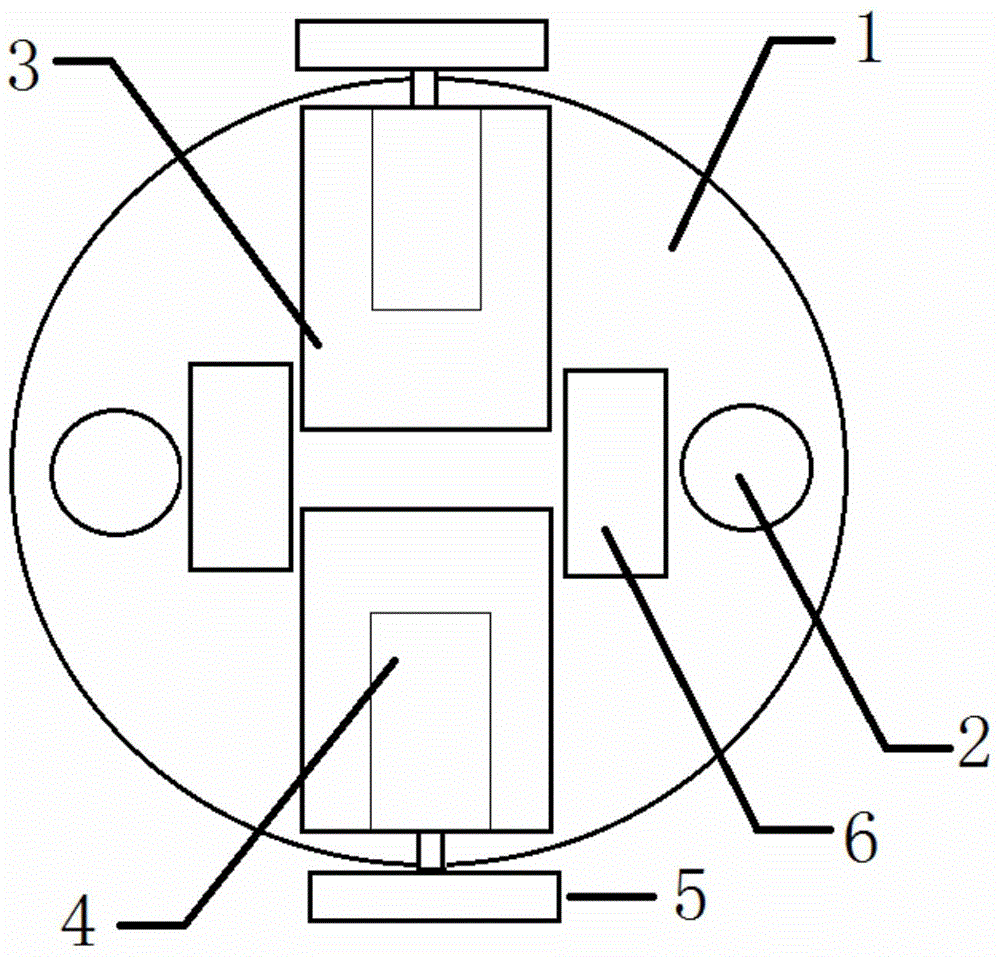

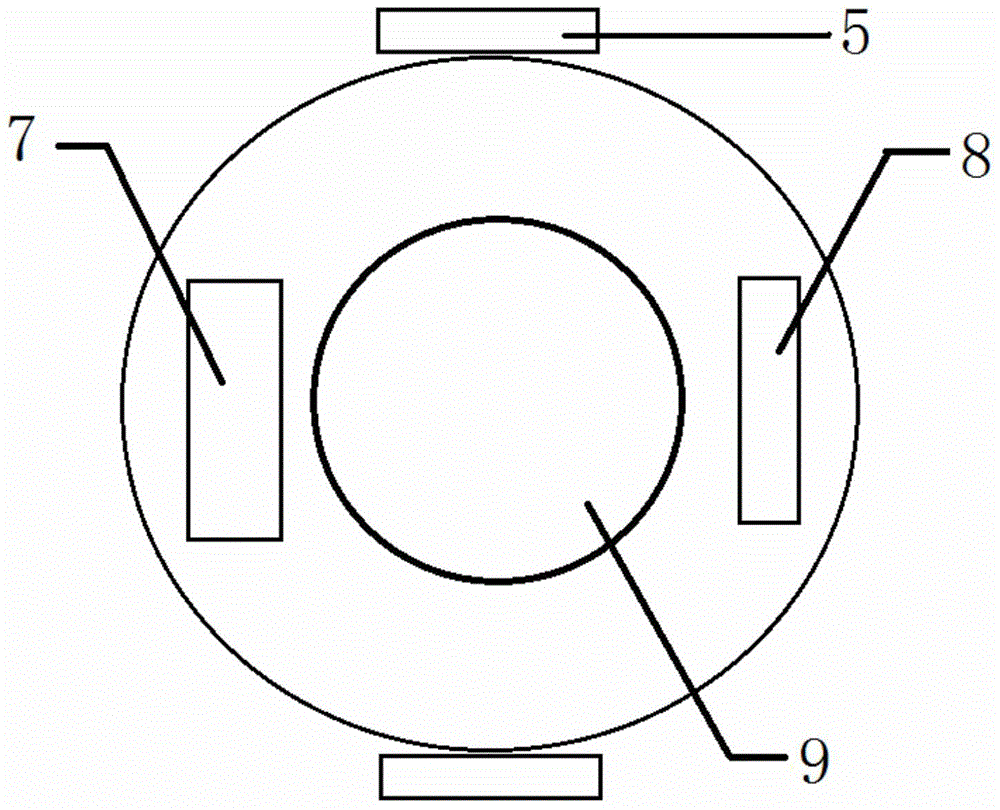

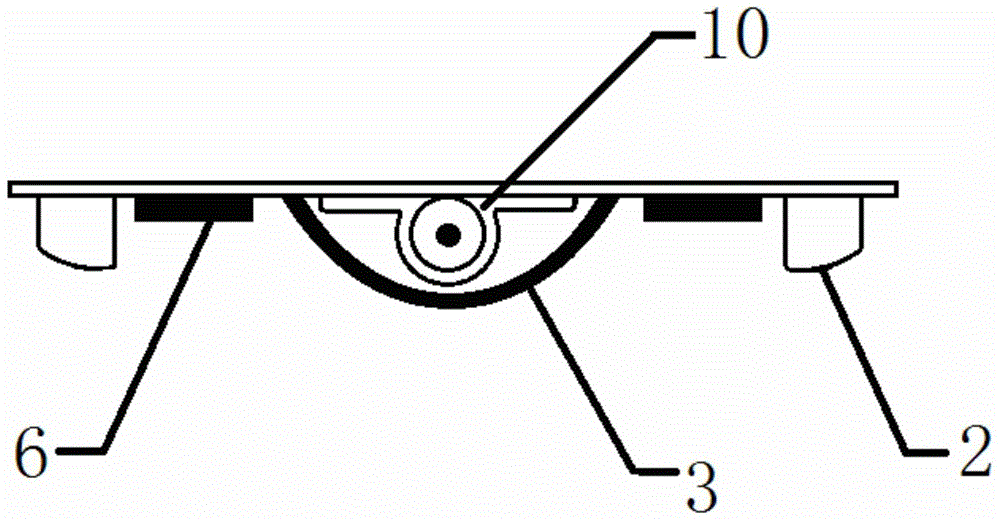

[0022] like Figure 1-Figure 5 As shown, a two-wheel autonomous mobile welding device, the welding device includes a bearing platform 1, the left and right ends of the bottom surface of the bearing platform 1 are symmetrically fixed with fixed motors 4, and the fixed motors 4 are respectively covered with There is a permanent magnet magnetic tile 3, the permanent magnet magnetic tile 3 is fixedly arranged on the bottom surface of the bearing platform 1 and is not in contact with the fixed motor 4, the cross section of the permanent magnet magnetic tile 3 is U-shaped, and the permanent magnet magnetic tile 3 The two ends of the tile 3 are fixed on the bottom surface of the bearing platform 1 by screws. The fixed motor 4 is fixedly connected to the bottom surface of the bearing platform 1 through the motor base 10 , and the motor shaft of the fixed motor 4 is provided with a wheel 5 . The front and rear ends of the bottom surface of the carrying platform 1 are fixedly and symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com