Heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization

A technology of detonator sensitivity and ammonium explosives, which is applied to explosives and other directions, can solve the problems of inconvenience, lack of detonator sensitivity, and poor detonation performance of heavy ammonium explosives, and achieves the effects of fine bubbles, fast foaming speed, and good detonator sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

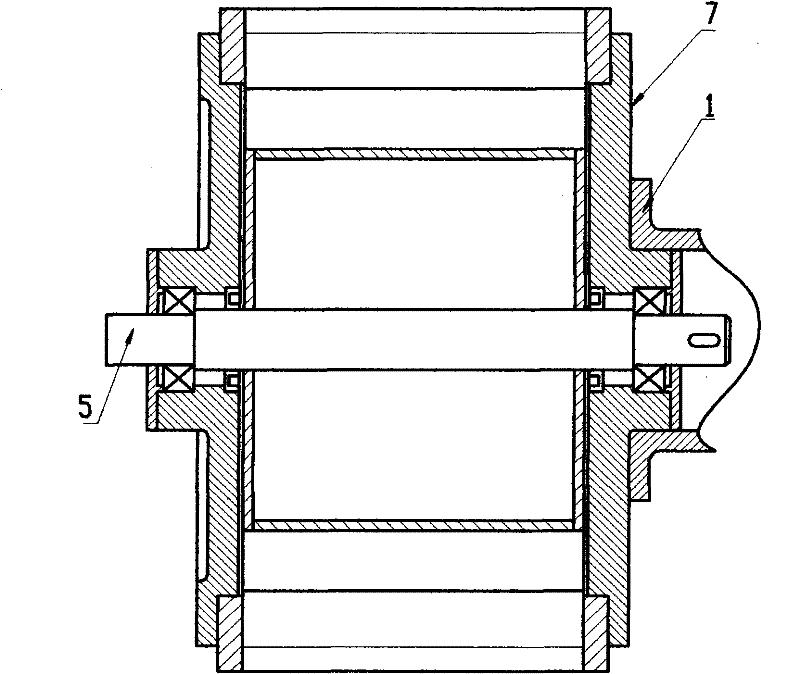

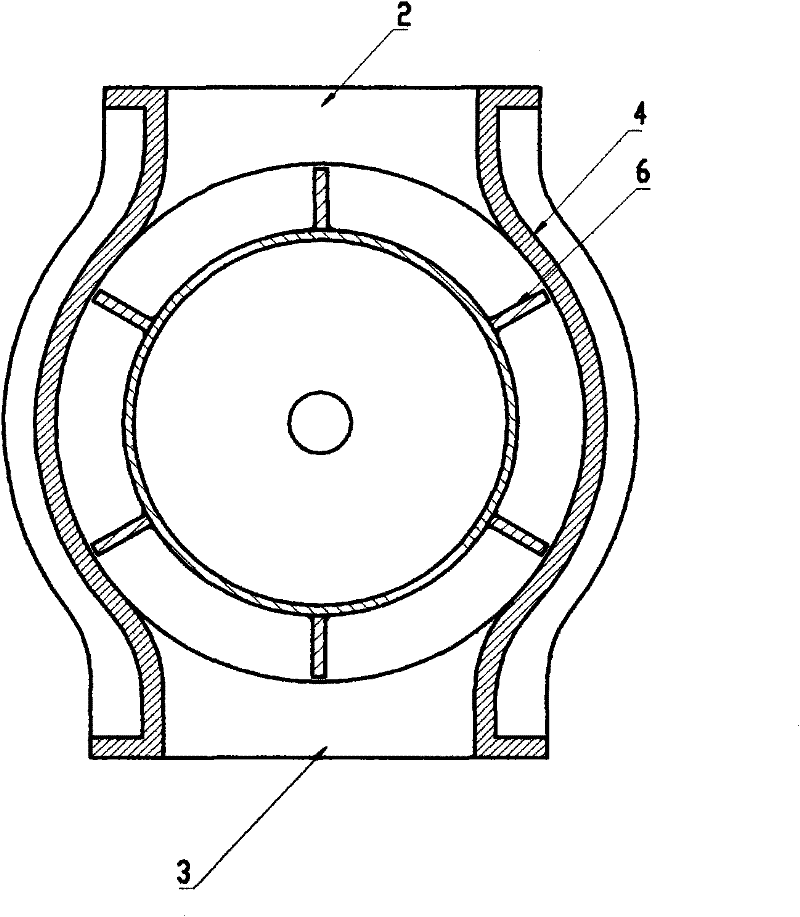

Image

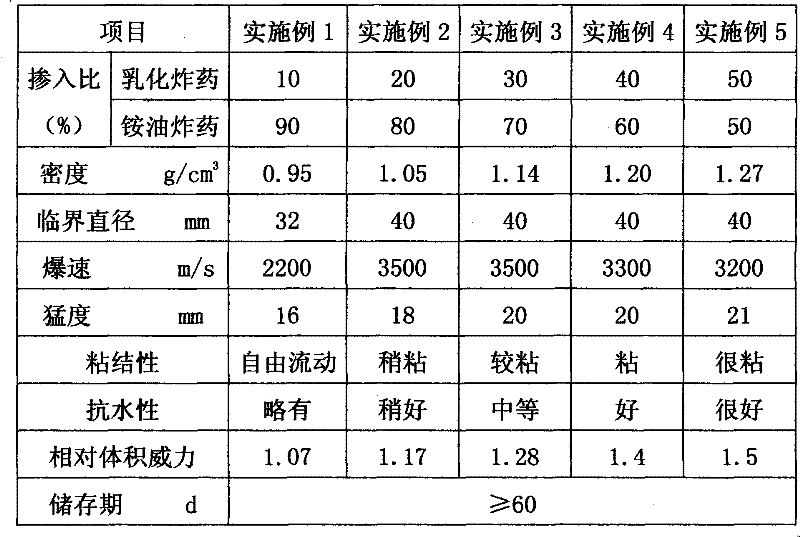

Examples

Embodiment 1

[0049] Latex matrix formula (mass percentage): ammonium nitrate: 82.1%, water: 11.5%, composite wax: 4.2%, sorbitan oleate: 2.2%;

[0050] Foaming agent formula (mass percentage): sodium nitrite: 15%, water: 85%;

[0051] Accelerator formula (mass percentage): H 2 C 8 h 4 o 4 -HC 8 h 4 o 4 - : 43%, magnesium nitrate: 5%, water: 51.5%, T-80: 1.5%;

[0052] Ammonium oil explosive formula (mass percentage): porous granular ammonium nitrate: 94.5%, diesel oil: 5.5%.

[0053] Implementation steps:

[0054] Preparation of porous granular ammonium oil explosives: use special equipment in advance, mix porous granular ammonium nitrate and diesel oil according to the formula requirements, put them into the ammonium oil explosives preparation tank, and set aside;

[0055] Preparation of latex matrix: According to the formula requirements, the ammonium nitrate is crushed and fully dissolved in water, and the temperature is kept at 95°C to make a water phase solution; after the c...

Embodiment 2

[0059] Latex matrix formula (mass percentage): ammonium nitrate: 73.4%, sodium nitrate: 8%, water: 10%, paraffin wax: 2%, microcrystalline wax: 2%, succinate: 2.6%;

[0060] Foaming agent formula (mass percentage): sodium nitrite: 20%, water: 80%;

[0061] Accelerator formula (mass percentage): H 3 PO 4 -H 2 PO 4 - : 40%, magnesium nitrate: 5%, water: 53.5%, LAE-9: 1.5%;

[0062] Ammonium oil explosive formula (mass percentage): porous granular ammonium nitrate: 94.5%, diesel oil: 5.5%.

[0063] Implementation steps:

[0064] Preparation of porous granular ammonium oil explosives: use special equipment in advance, mix porous granular ammonium nitrate and diesel oil according to the formula requirements, put them into the ammonium oil explosives preparation tank, and set aside;

[0065] Preparation of latex matrix: According to the requirements of the formula ratio, the ammonium nitrate and sodium nitrate are crushed and fully dissolved in water, and the temperature is k...

Embodiment 3

[0069] Latex matrix formula (mass percentage): ammonium nitrate: 81%, water: 12.2%, microcrystalline wax: 2.5%, vaseline: 2%, succinate: 2.3%;

[0070] Foaming agent formula (mass percentage): sodium nitrite: 25%, water: 75%;

[0071] Accelerator formula (mass percentage): H 3 PO 4 -HPO 4 2- : 45%, calcium nitrate: 5%, water: 49.5%, T-80: 1.5%;

[0072] Ammonium oil explosive formula (mass percentage): porous granular ammonium nitrate: 94.5%, diesel oil: 5.5%.

[0073] Implementation steps:

[0074] Preparation of porous granular ammonium oil explosives: use special equipment in advance, mix porous granular ammonium nitrate and diesel oil according to the formula requirements, put them into the ammonium oil explosives preparation tank, and set aside;

[0075] Preparation of latex matrix: According to the formula requirements, the ammonium nitrate is broken and fully dissolved in water, and the temperature is kept at 100°C to make a water phase solution; after the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com