Yield Predictive Feedback for Control Equipment Engineering Systems

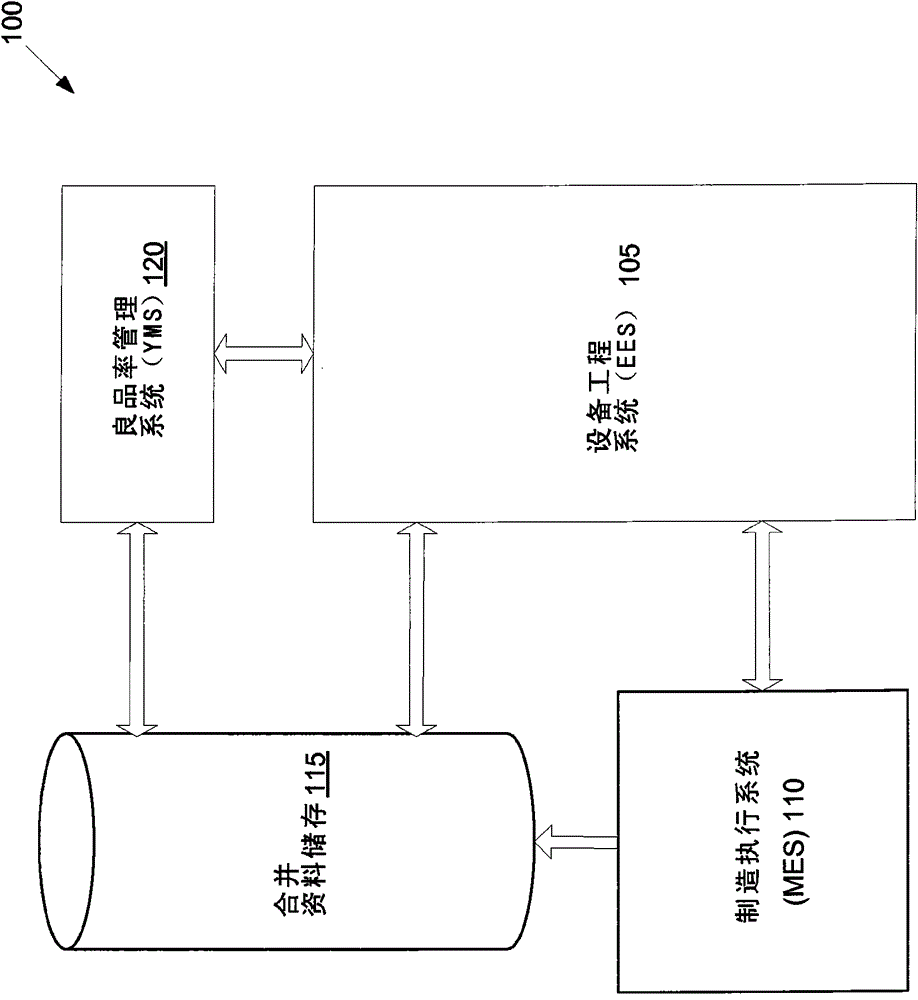

A technology of yield rate and equipment, which is applied in the field of yield rate prediction, can solve the problems of no subsystems and no EES subsystems to provide predicted yield information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

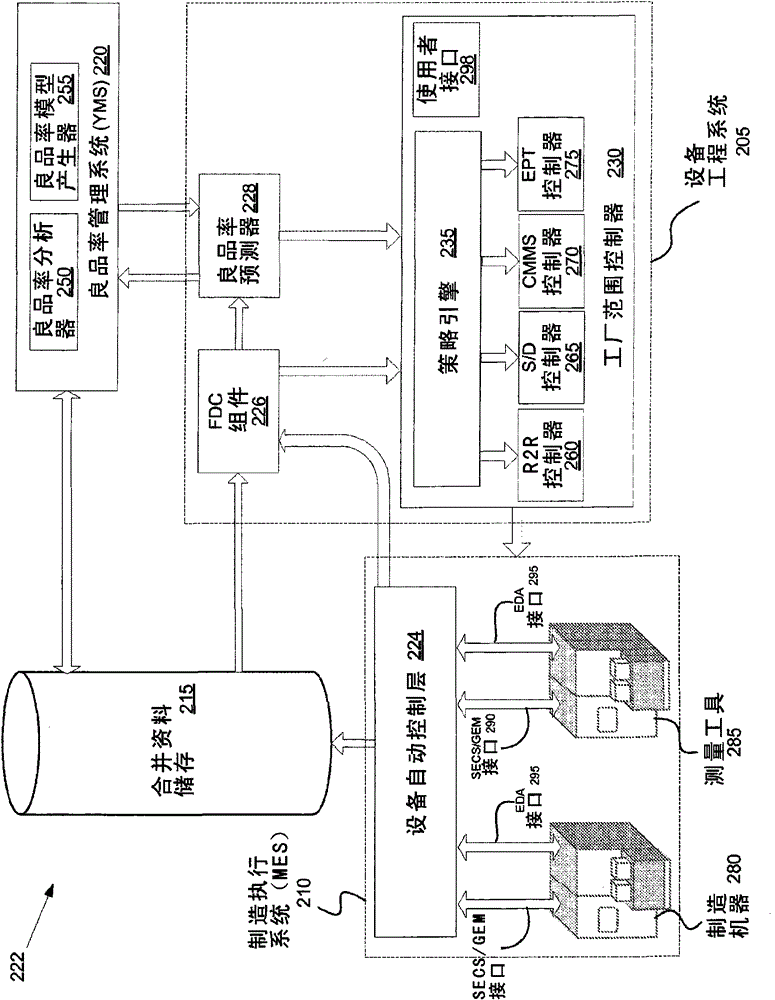

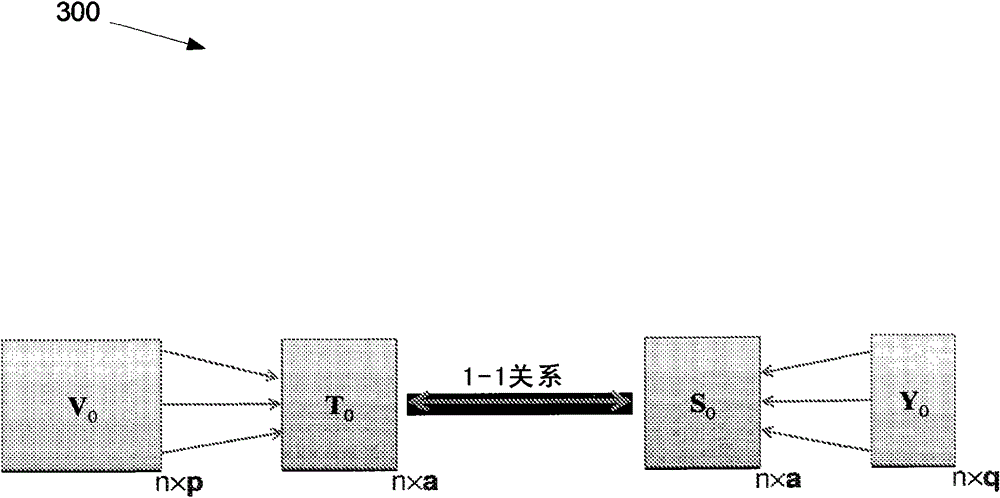

[0033] Described herein is a method and apparatus for performing automated actions in response to yield predictions. A backend yield prediction is generated based on data associated with the manufacturing process, the manufacturing tool, and / or the manufactured product. The back-end yield forecast is communicated to one or more components of the equipment engineering system. In one embodiment, the yield forecast is received by a schedule and dispatch controller. Based on the yield prediction, the weight of the manufacturing tool is adjusted in the routing algorithm. A cost-benefit analysis is calculated that identifies the costs and benefits of manufacturing future products on the manufacturing tool. Based on the cost-benefit analysis, a decision is made as to whether to process future products on the manufacturing tool.

[0034] In the following description, numerous details are set forth. However, it will be understood by those skilled in the art that the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com