Internal board structure for printed circuit board

A technology for printed circuit boards and inner-layer boards, applied to printed circuit components, circuit substrate materials, etc., can solve problems such as poor wrinkles and lack of glue, and achieve the effects of convenient pressing, sufficient glue filling, and improved production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

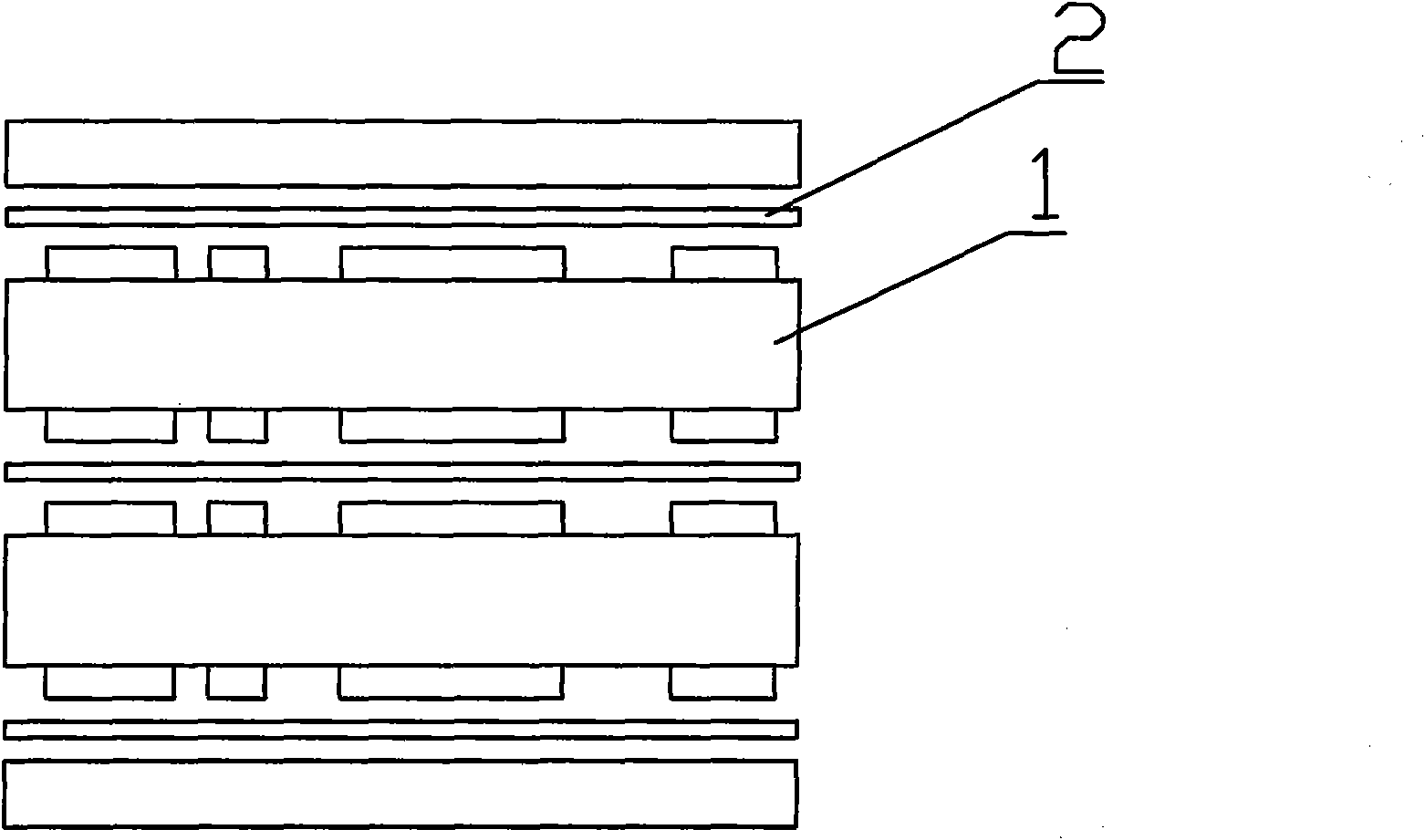

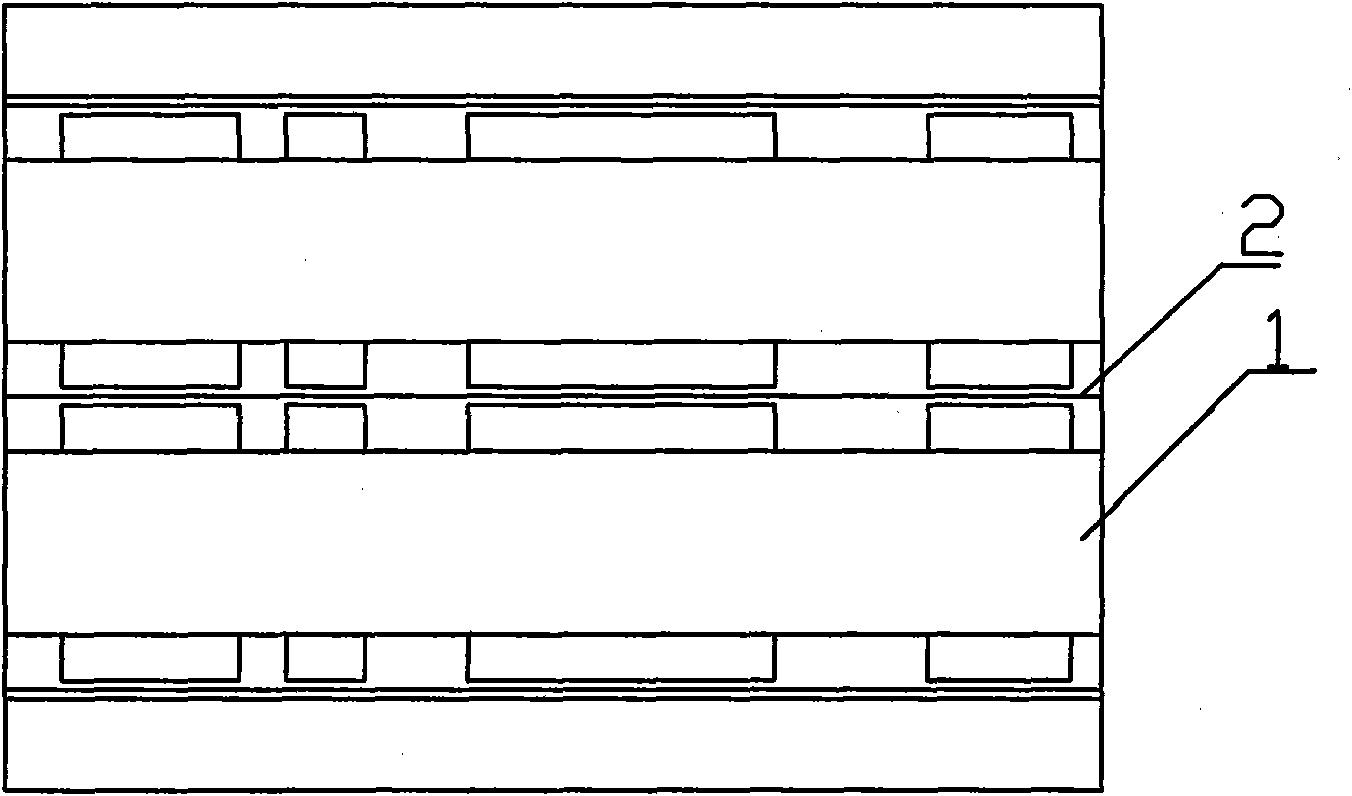

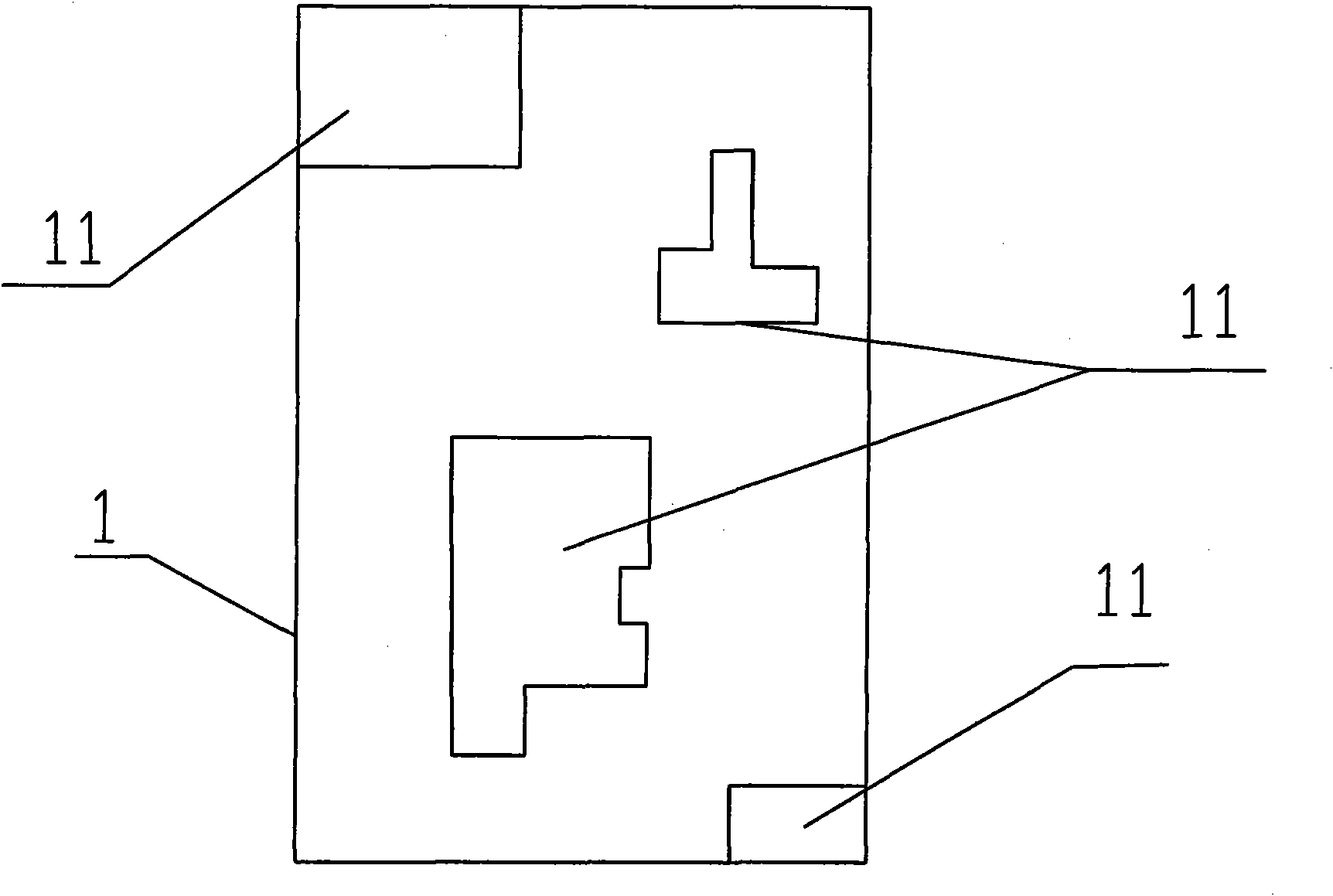

[0015] see Figure 1 to Figure 3 , this embodiment provides an inner board structure applied to printed circuit boards, including an inner board 1 and a scraping glue area 11 arranged on the inner board 1; the surface of the scraping glue area 11 is fully plated There is a copper layer; the upper and lower panels of the inner layer board 1 are laminated with a film 2; the inner layer board 1 adopts an all-copper structure to avoid the fluidity of the glue during the lamination process, which will cause part of the glue to fill up above the copper-free area.

[0016] In this embodiment, the film 2 is a resin film. In this implementation, multiple inner boards with circuits are passed through the press, and the resin film is used to bond them toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com