Direct-drive power generation system

A power generation system, direct-drive technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced energy conversion efficiency, increased manufacturing cost of ship power station equipment, low energy conversion efficiency of generators, etc., to achieve reduction Effects of small harmonic components, simplified structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

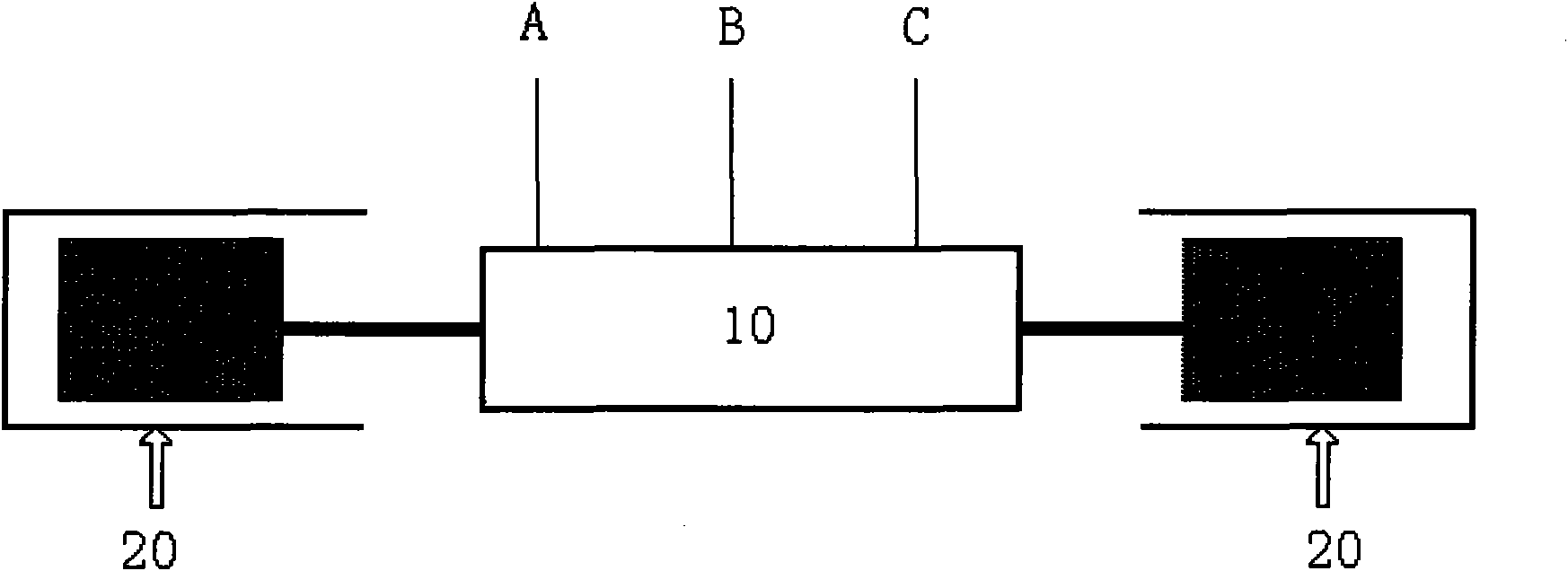

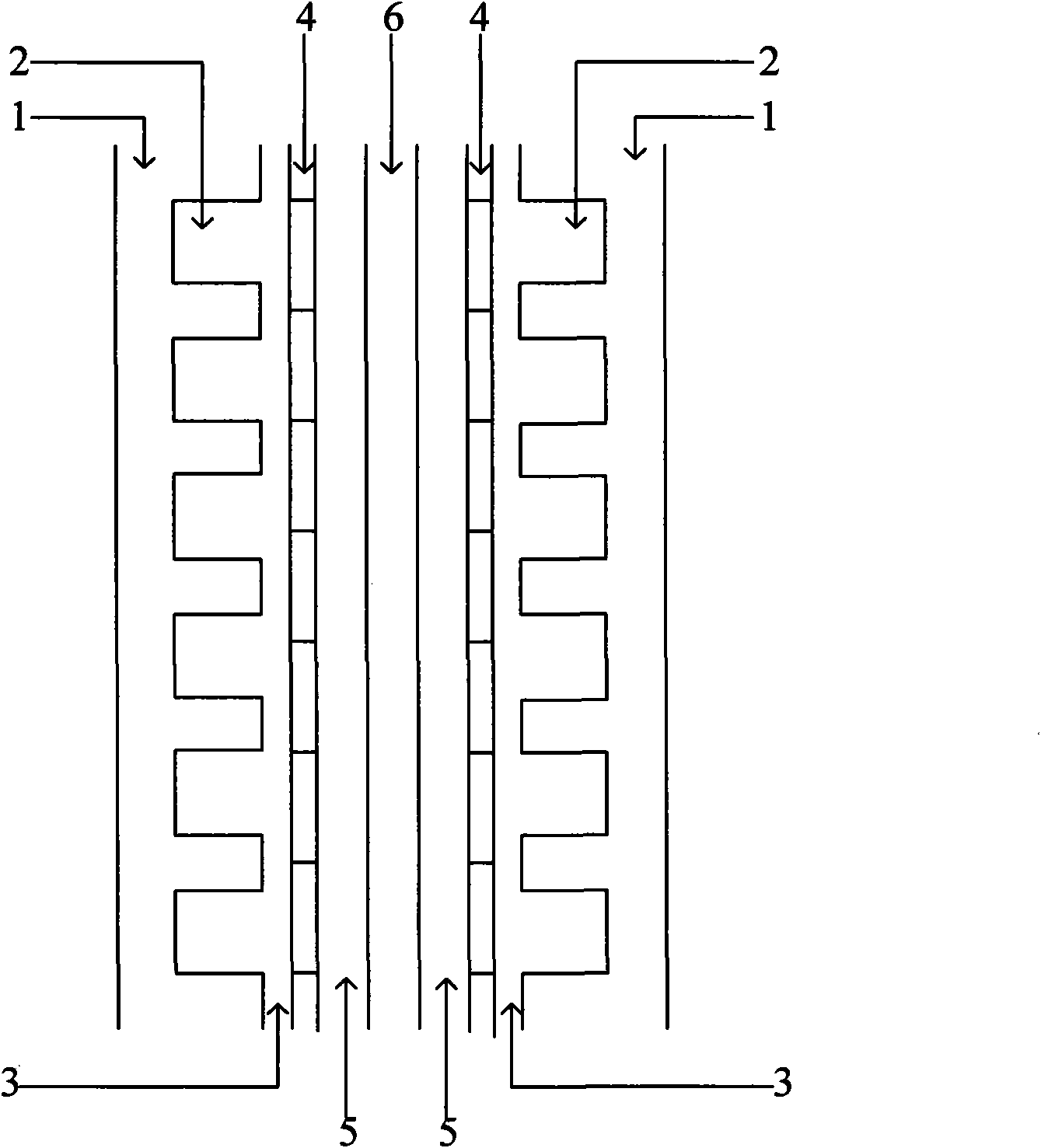

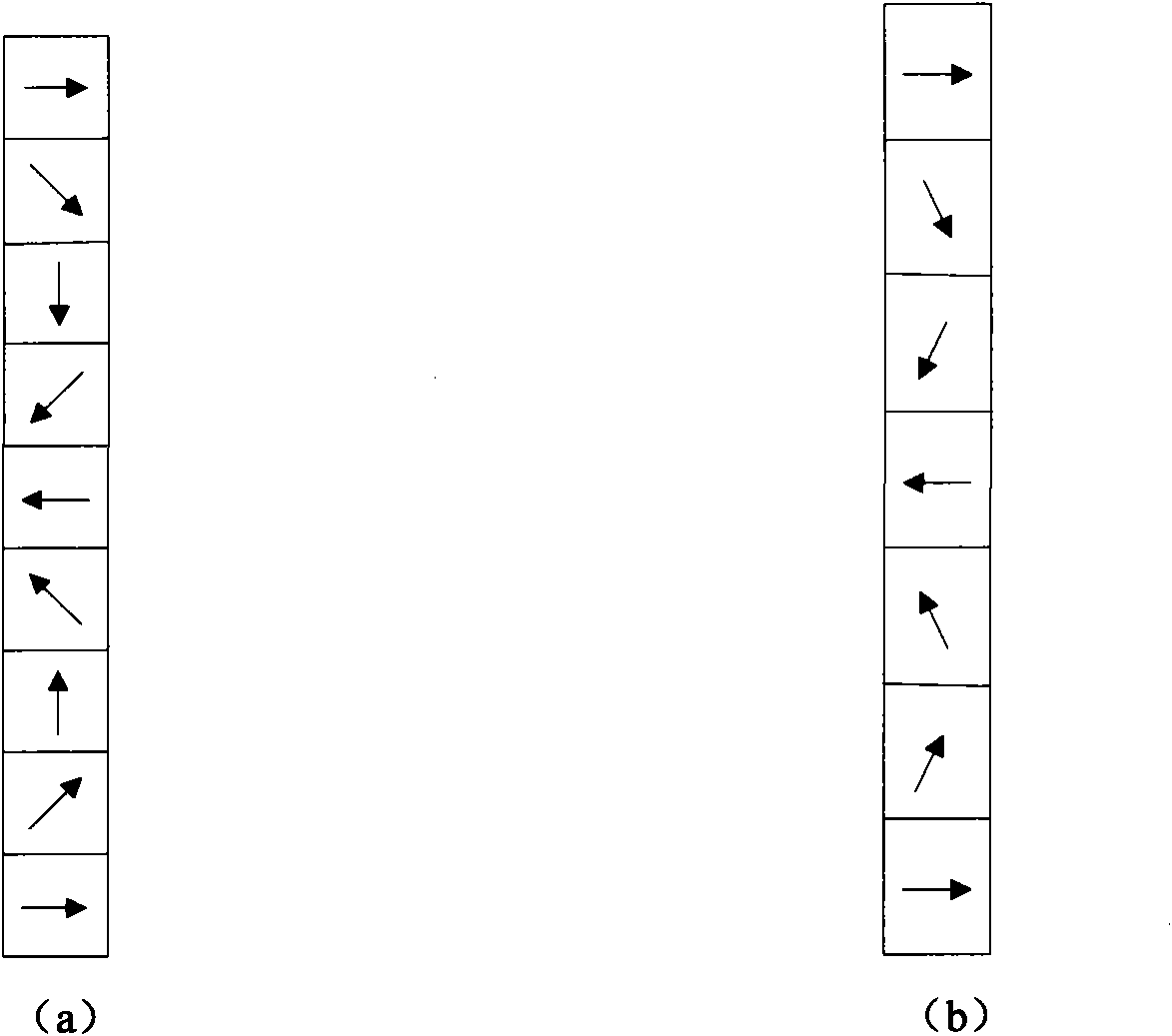

[0017] A kind of direct drive type power generation system of the present invention, see figure 1 with figure 2 . The power generation system includes a linear motion internal combustion engine 20 and a permanent magnet linear generator 10 , the piston of the linear motion internal combustion engine 20 is axially connected to both ends of the permanent magnet linear generator 10 . The permanent magnet linear generator 10 includes a primary core 1, a primary coil 2, a secondary core 5 and a non-magnetic material shaft 6, and the primary core 1, the primary coil 2, the secondary core 5, and the non-magnetic material shaft 6 are in order from outside to inside arrangement; the primary coil 2 is wound on the inner side of the primary iron core 1, the non-magnetic material shaft 6 is embedded in the inner side of the secondary iron core 5, and the permanent magnet 4 of the Halbach array is set on the outer side of the secondary iron core 5, and makes the permanent magnet of the H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com