Positive pressure jet spiral sampling drill

A sampling drill bit and screw technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of complex process, long sampling time, hindering the production efficiency of coal seams, etc., and achieve the effect of good continuity and simplified sampling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

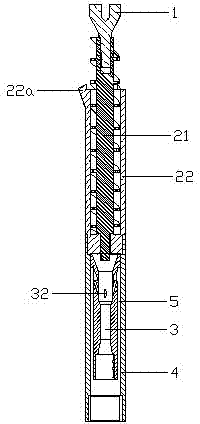

[0014] figure 1 It is a structural sectional view of the present invention; figure 2 It is a structural sectional view of the annular nozzle injector of the present invention. As shown in the figure, a positive pressure injection spiral sampling drill bit includes a sampling drill bit 1, a screw pump 2, an injector 3 and a joint outer sleeve 4 from front to back; the screw pump includes a rotor 21 and a stator 22, and the rotor 21 The front end is fixedly connected with the sampling drill bit 1, and the front end of the stator 22 is provided with a reaming drill bit 22a; both the rotor 21 and the stator 22 of the screw pump are fixedly connected with the front end of the joint outer sleeve 4, and the injector 3 is arranged in the joint outer sleeve 4. The pump 2 communicates with the central through hole of the injector, and an annular passage I5 is formed between the injector and the pipe wall of the joint outer sleeve, and a gas injection hole is arranged between the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com