Automotive door lock system for preventing deadlocking caused by frontal collision of automotive door

A frontal collision and door lock technology, which is applied in the field of car door locks, can solve problems such as unreliable structure, increased vehicle weight, and inconformity with the development trend of energy-saving and emission-reduction technologies, and achieve the effect of improved safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

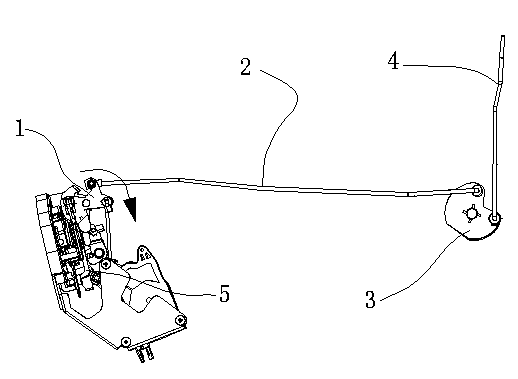

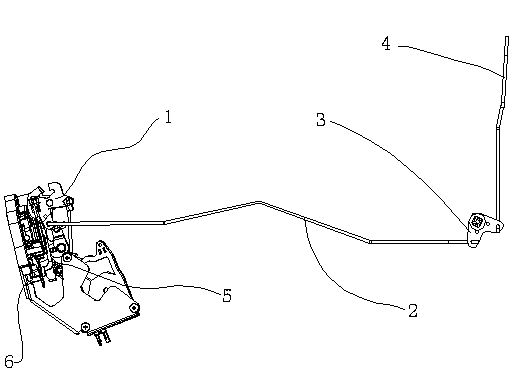

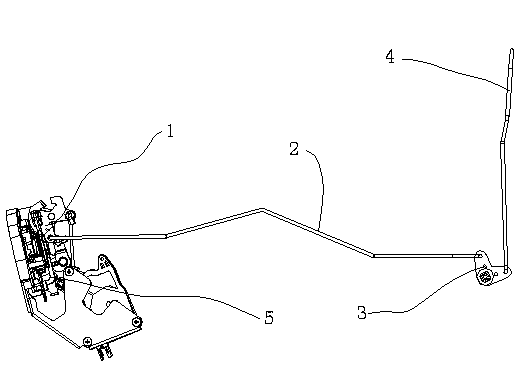

[0012] Such as figure 2 , 3 As shown in , 4, a car door lock system for preventing car doors from being locked due to frontal collision, including a lock body fixedly connected to the car door, the lock plate 1 of the lock body is located at the upper part of the lock body, and the lock plate 1 is arranged in an up-down direction, wherein Or the upper part is hinged with the frame of the lock body, the lower end of the locking plate 1 is hinged with the rear end of the transverse safety rod 2, the front end of the transverse safety rod 2 is hinged with the rotating clip 3, the rotating clip 3 is hinged with the door, and the vertical safety rod 4 is connected with the rotating clip 3 Hinged, the vertical safety rod 4 and the horizontal safety rod 2 form a transmission cooperation along the axis of the two rods through the rotating clip 3, that is to say: the horizontal safety rod 2, the rotating clip 3, and the vertical safety rod 4 can be figure 1 connection as shown in , o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com