Tilting mechanism, running mode of tilting mechanism, application of tilting mechanism in tilting rotorcraft

A tilting mechanism and rotor tilting technology, applied in rotorcraft, motor vehicles, transportation and packaging, etc., can solve the problems of low control accuracy and poor stability, and achieve self-locking mechanism, small driving force, and elimination of external forces. The effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

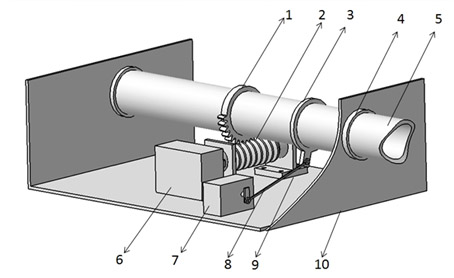

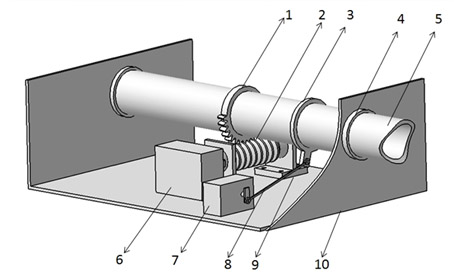

[0011] figure 1 The two middle rotors are connected by the tilting shaft 5, and the tilting mechanism is installed in the middle of the fuselage, and its internal structure is shown in the figure. Worm wheel 1 links to each other with tilting shaft 5, is fixed by screw. The worm screw 2 is driven by the steering gear 6, and the two ends are supported by bearing blocks 9. The swivel 3 is connected with the tilting shaft 5 and fixed by screws. The pull rod 8 connects the angle sensor 7 and the swivel 3, the tilting shaft 5 drives the angle sensor 7 to rotate through the swivel 3 and the pull rod 8, and the angle sensor 7 feeds back the deflection angle to the control circuit in the form of an electrical signal. The assembly relationship of the whole tilting mechanism is as shown in the figure, the tilting shaft 5 is connected to the mounting frame 10 through the bearing 4, and the worm bearing seat 9 is fixed on the lower surface of the mounting frame 10 with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com