Tooth row positioning device and working method thereof

A technology of positioning device and tooth row, which is applied in printing, printing presses, general parts of printing machinery, etc., can solve the problems that the adjustment device can not completely solve, affect the accuracy of the equipment, and reduce the accuracy of the equipment, so as to improve the chain stretching problem, The effect of reducing maintenance and installation costs and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

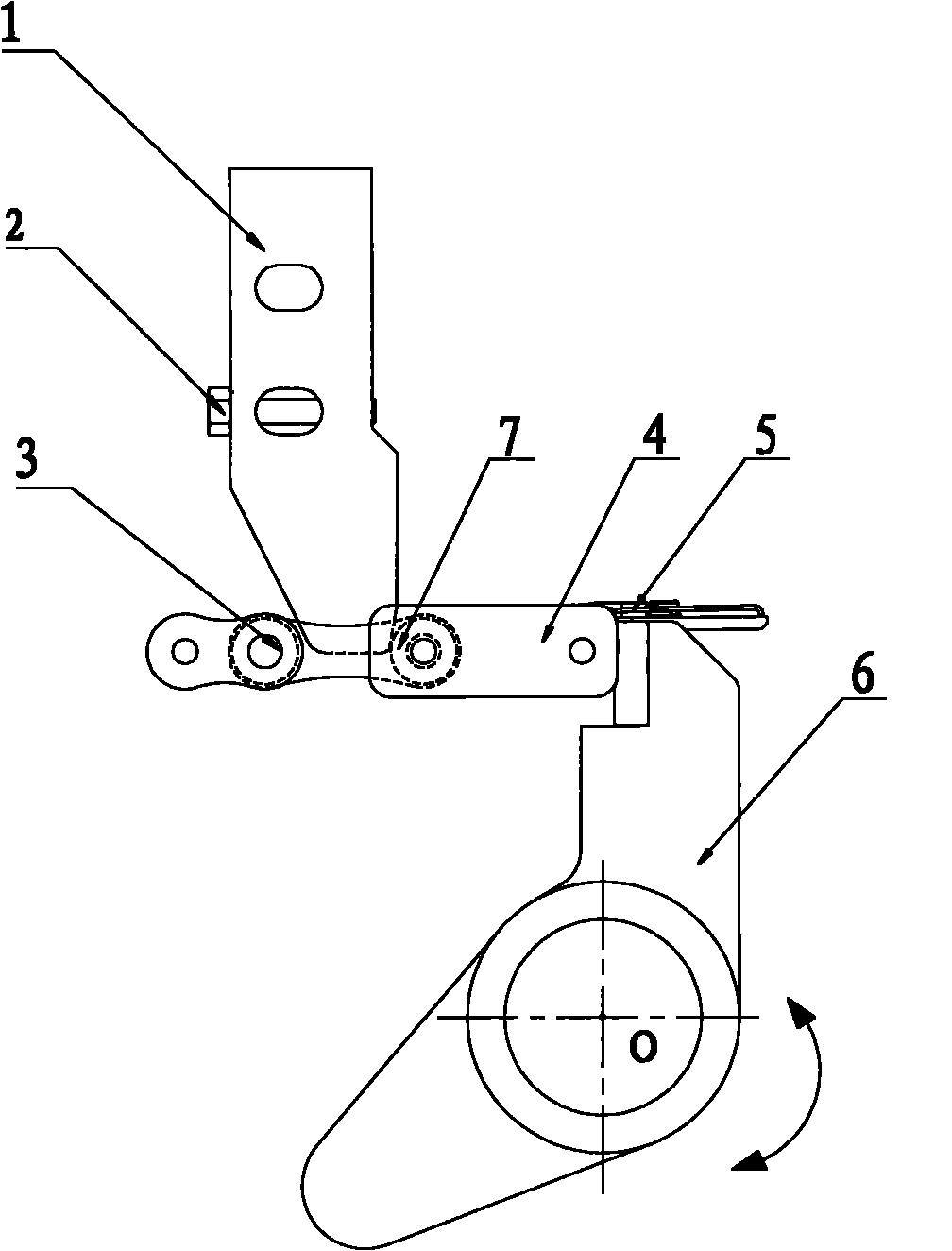

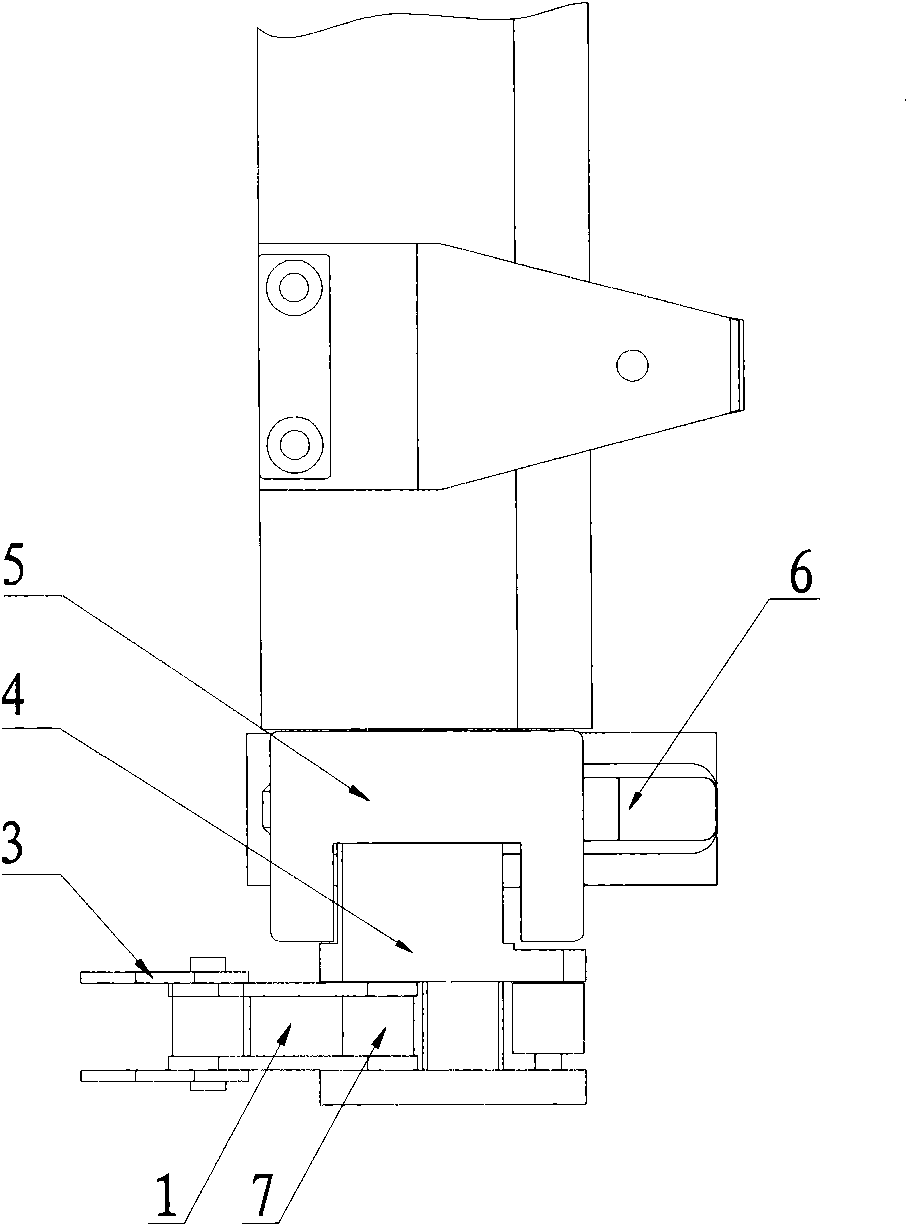

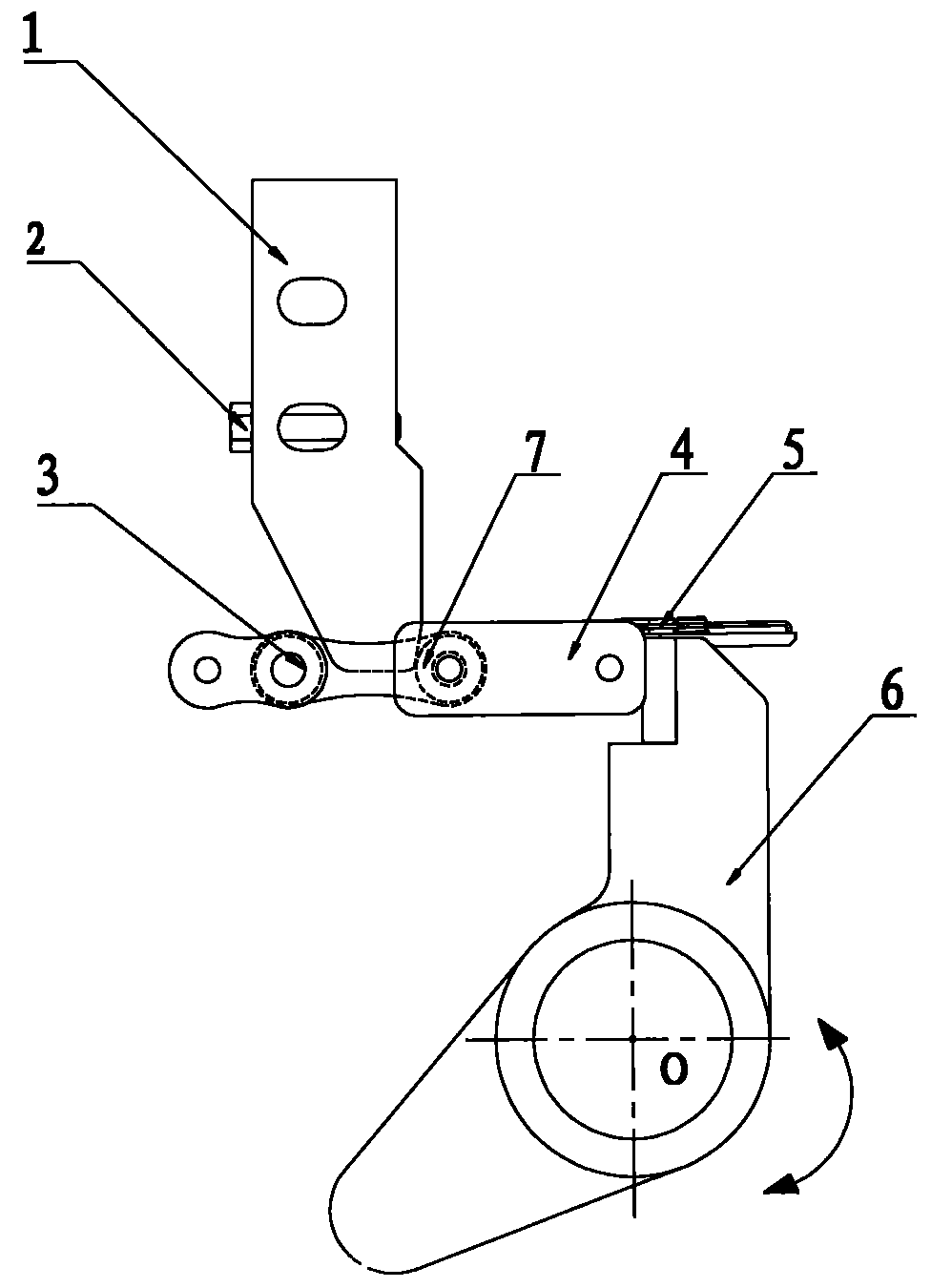

[0019] Embodiment: a kind of row of teeth positioning device (see figure 1 , figure 2 ), is characterized in that it is made of chain positioning block 1, adjusting screw 2, chain 3, connecting block 4, tooth row body 5, rear positioning swing bar 6 and positioning roller 7; said chain positioning block 1, adjusting screw 2. The chain 3, the connecting block 4, the rear positioning swing bar 6 and the positioning roller 7 are all symmetrically installed on both sides of the tooth row body 5; the said connecting block 4 is connected to the chain 3; the said chain positioning block 1 is located on the Directly above the chain link of the chain 3 connected to the connecting block 4, the chain positioning block 1 is fixed on the fixture; the said positioning roller 7 is a roller on the connecting block 4 chain link; the said tooth row body 5 The two ends are respectively fixedly connected on the connection block 4; the said back positioning swing link 6 is a symmetrical part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com