Variable-frequency power saver of single-phase injection molding machine

A single-phase inverter, injection molding machine technology, used in electrical components, AC motor control, control systems and other directions, can solve problems such as power waste, and achieve wide application prospects, simple and practical structure, good economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

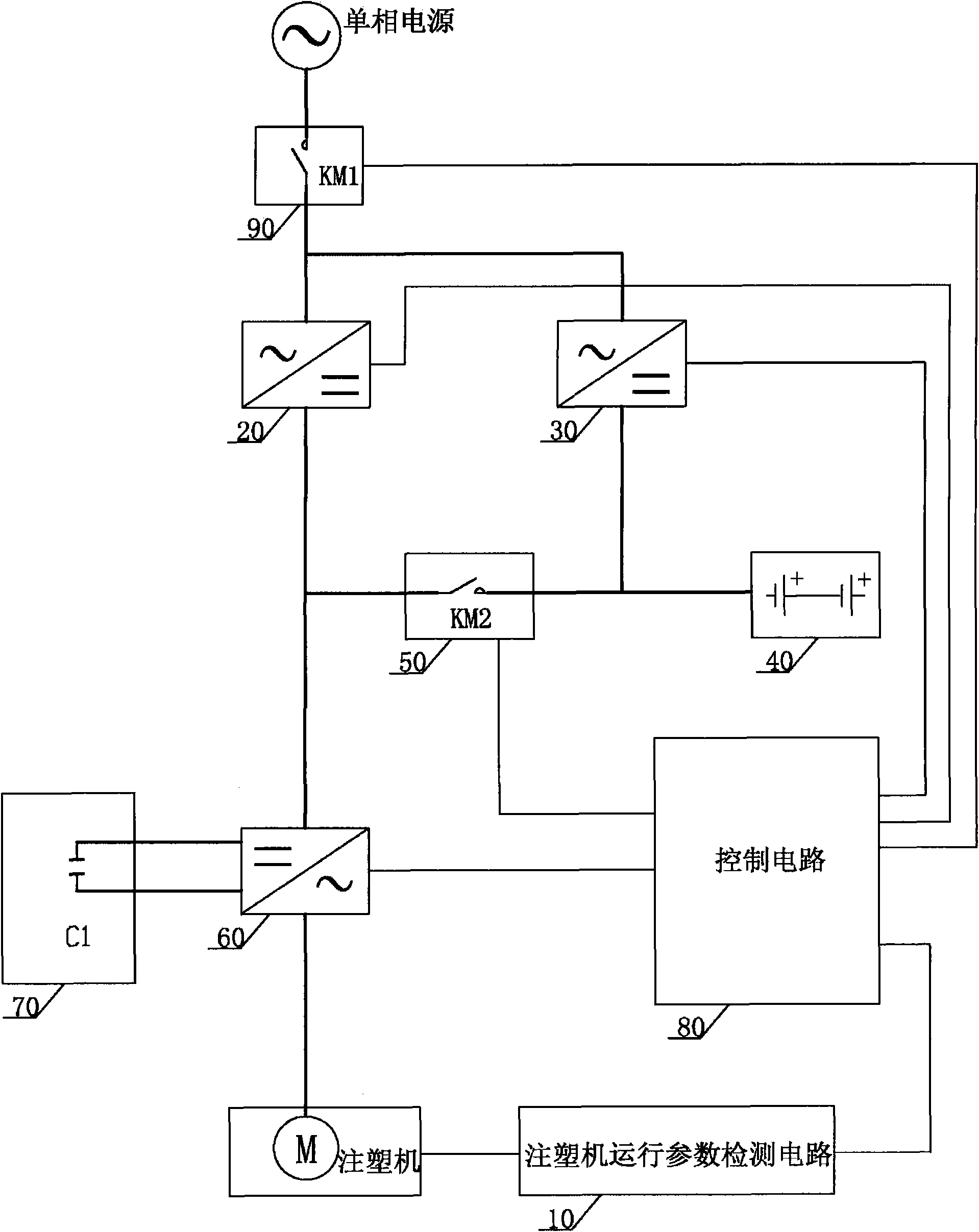

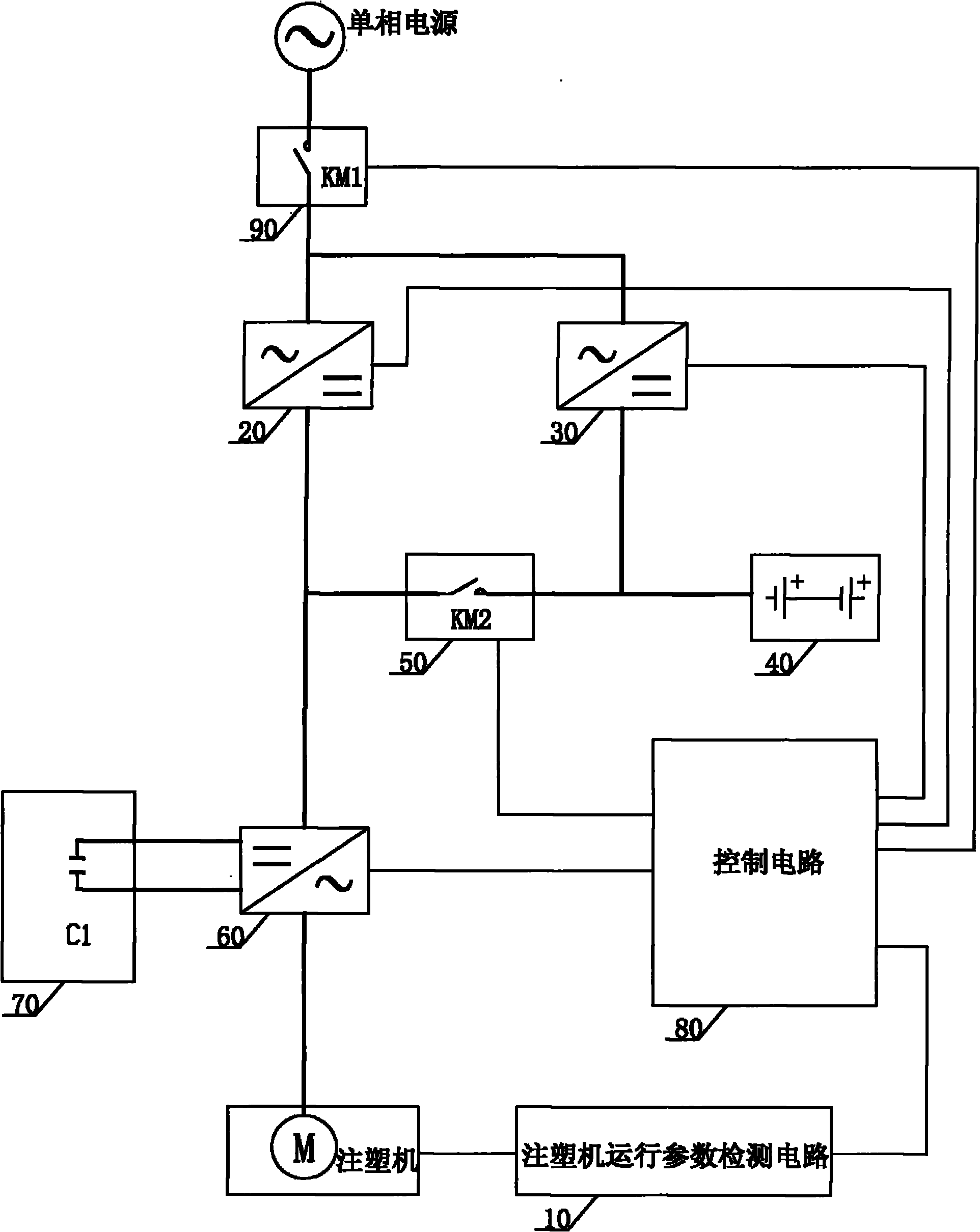

[0011] Referring to the accompanying drawings, taking a 220V, 50HZ, single-phase, 1.5KW injection molding machine as a reference, this single-phase injection molding machine frequency conversion power saver includes an injection molding machine operating parameter detection circuit (10), a single-phase rectification circuit (20), charging circuit (30), battery (40), battery switch (50), single-phase inverter (60), capacitor (70), control circuit (80), single-phase power contactor (90). The single-phase power supply of the external grid is connected to the input end of the single-phase power contactor (90), and the output end of the single-phase power contactor (90) is respectively connected to the input end of the single-phase rectification circuit (20) and the input terminal of the charging circuit (30). The output terminal of the single-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com