Reinforced packaging assembly

A packaging group, packaging technology, applied in the direction of packaging, transportation and packaging, containers with multiple items, etc., which can solve problems such as bending or twisting of circumferential belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

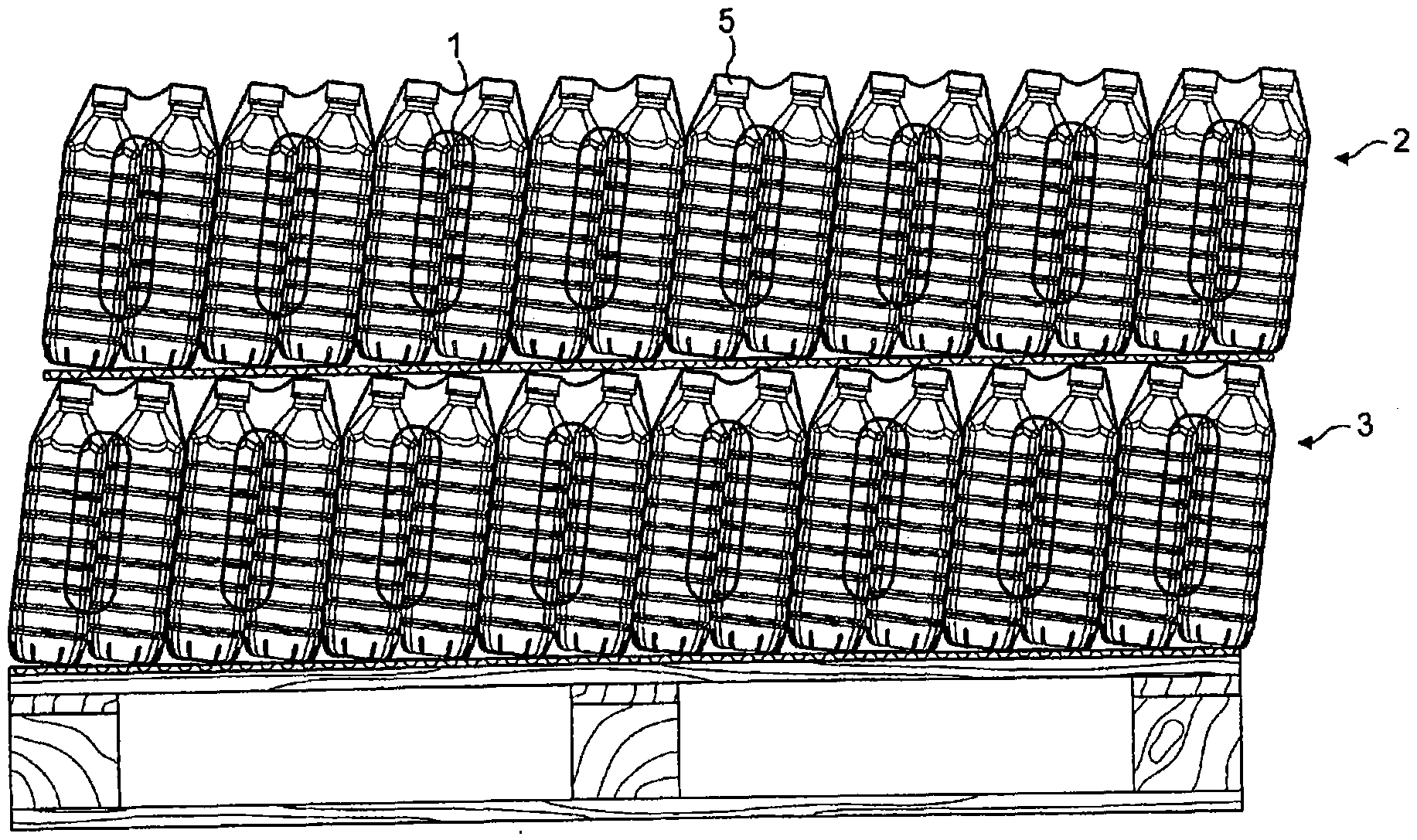

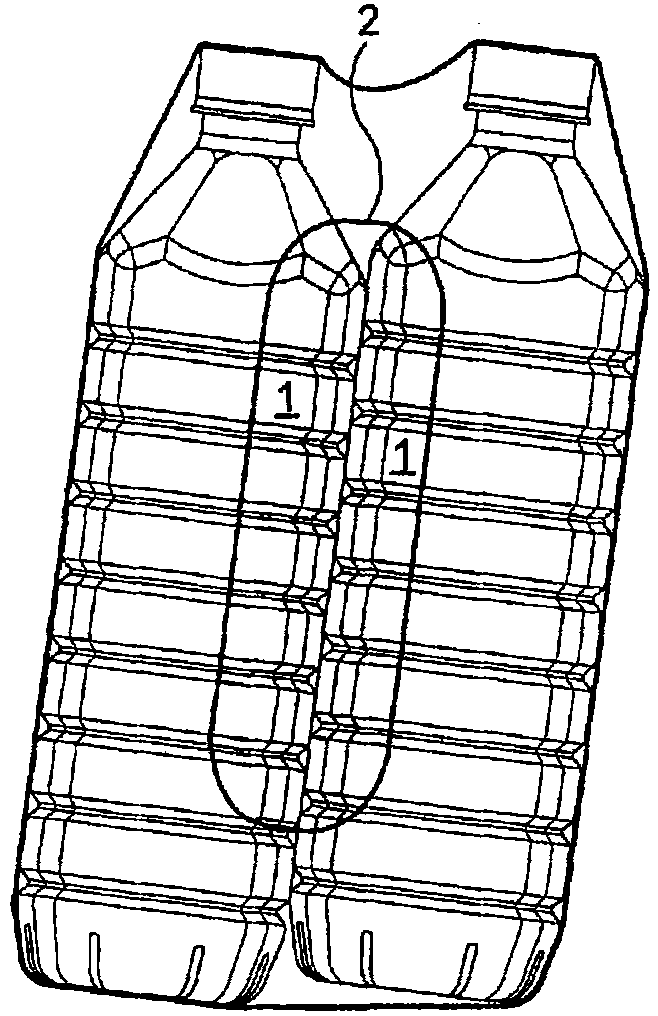

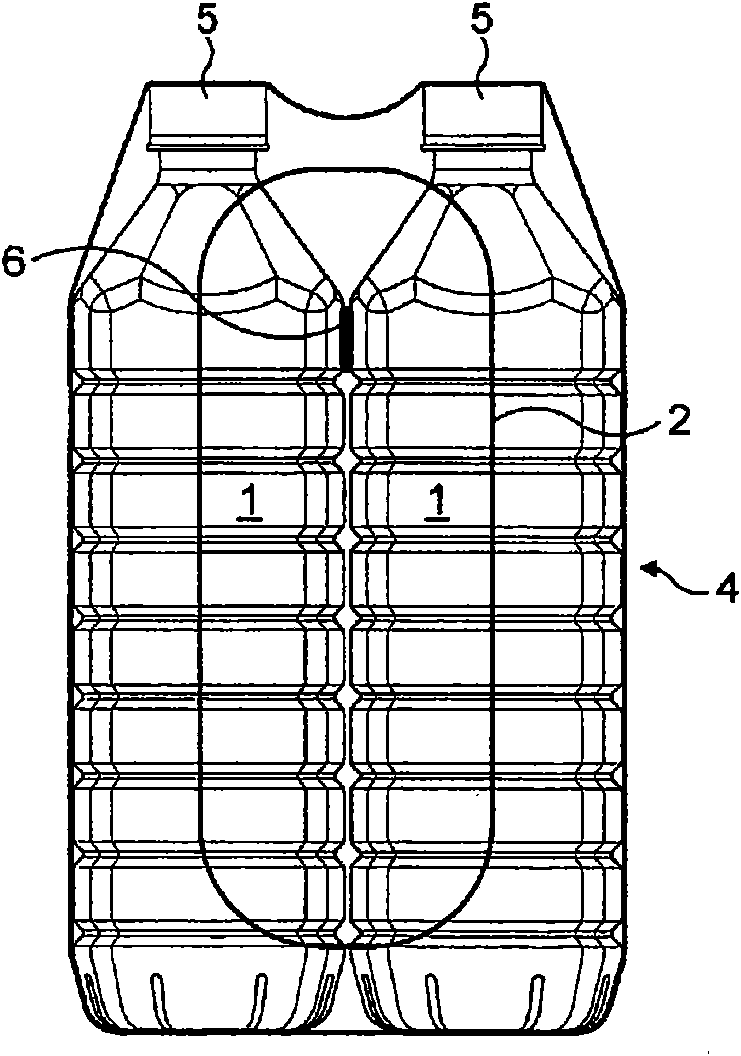

[0032] image 3 with Figure 4 A secondary packaging 4 according to the invention is shown, comprising a group of primary packagings, in the example of embodiment shown in the figure, the primary packagings are made of polyethylene terephthalate (PET) The finished water bottle 1 is closed by a screw cap 5. The water bottles 1 are grouped and held together in groups by a heat shrinkable thermoplastic film wrap 2 surrounding the group of bottles.

[0033] In order to hold the bottles 1 together in a fixed attachment, glue spots 6 are arranged between the bottles, more particularly on the sides of adjacent bottles. The dots of glue are such that the cohesion is sufficient to prevent relative movement of the bottles against each other during transport and handling of the secondary packaging 4 .

[0034] Basically, it has been found that the glue must be sufficient to resist a transverse force acting on the secondary packaging 4 of at least 0.2 Newton.

[0035] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com