Touch screen liquid crystal display module and touch drive method thereof

A liquid crystal display module and touch-driven technology, applied in static indicators and other directions, can solve problems such as the unfavorable thinning trend of liquid crystal panels, increase the thickness of the module, and increase the production cost, so as to save the shielding layer, simplify the structure, reduce the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

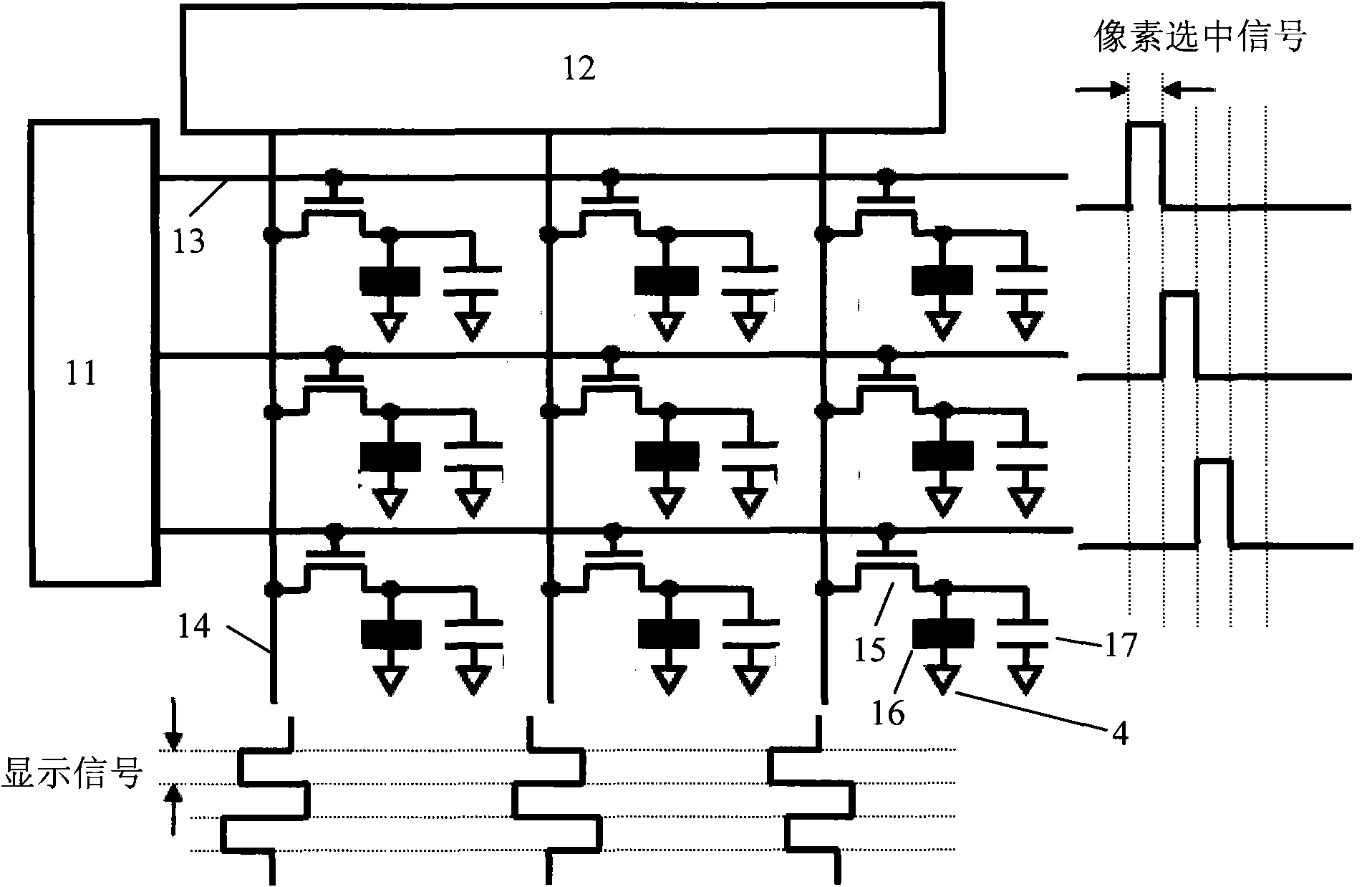

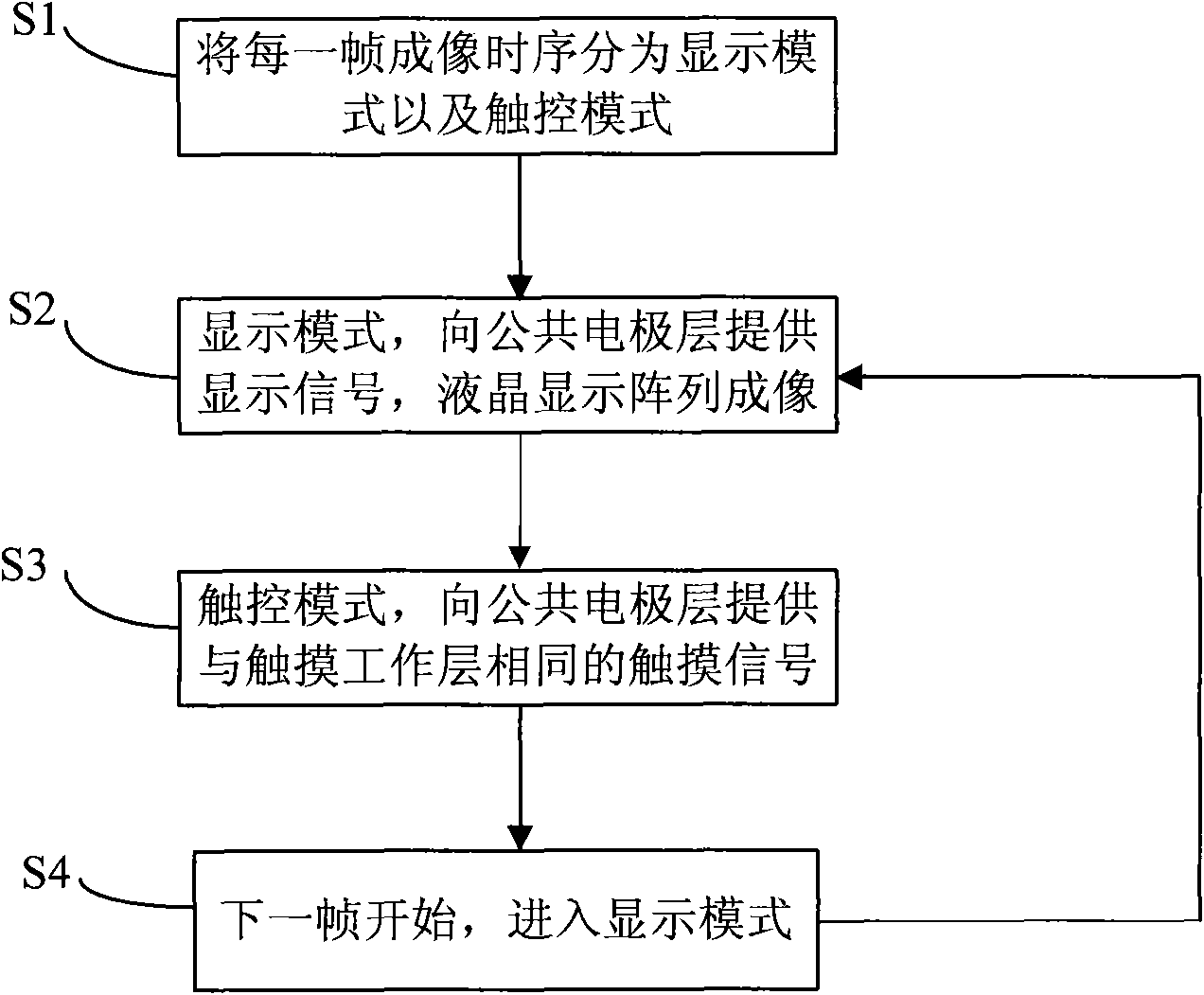

[0028] In the prior art, the touch screen and the liquid crystal display are not only separated in structure, but also work independently of each other. While the touch screen senses the user's touch signal, the LCD screen at the bottom is also imaging and displaying frame by frame. Therefore, a shielding layer needs to be added between the touch screen and the LCD screen to eliminate the noise interference from the LCD screen to the touch screen.

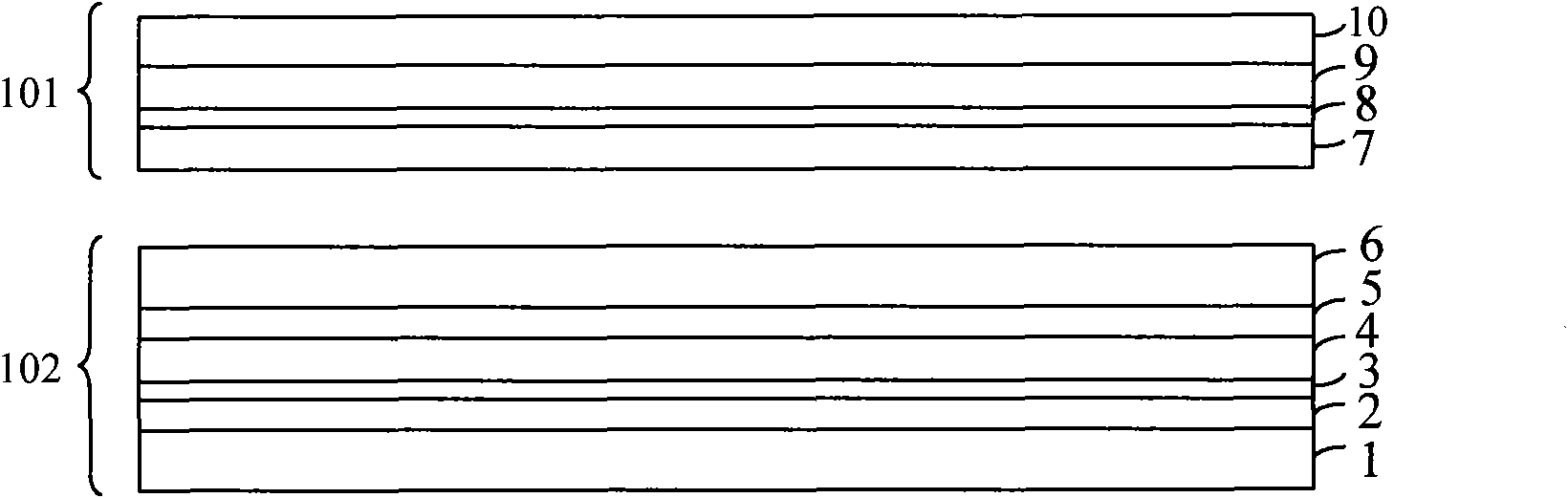

[0029] The scanning frequency of a standard liquid crystal display is 60Hz, that is, each frame time is about 16.7 milliseconds; however, for most thin-film transistors of liquid crystal display arrays, the gate pulse width is relatively small, and the time to complete one frame of progressive imaging may be less than Standard time for each frame. Taking the 240x320 pixel QVGA liquid crystal display as an example, the widest pulse that the gate of the thin film transistor can respond to only needs 52 microseconds. figure 2 In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com