Natural gas electromagnetic valve

A solenoid valve, natural gas technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of impact flow monitoring equipment, etc., to avoid sudden increase in flow and prevent violent impact monitoring equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

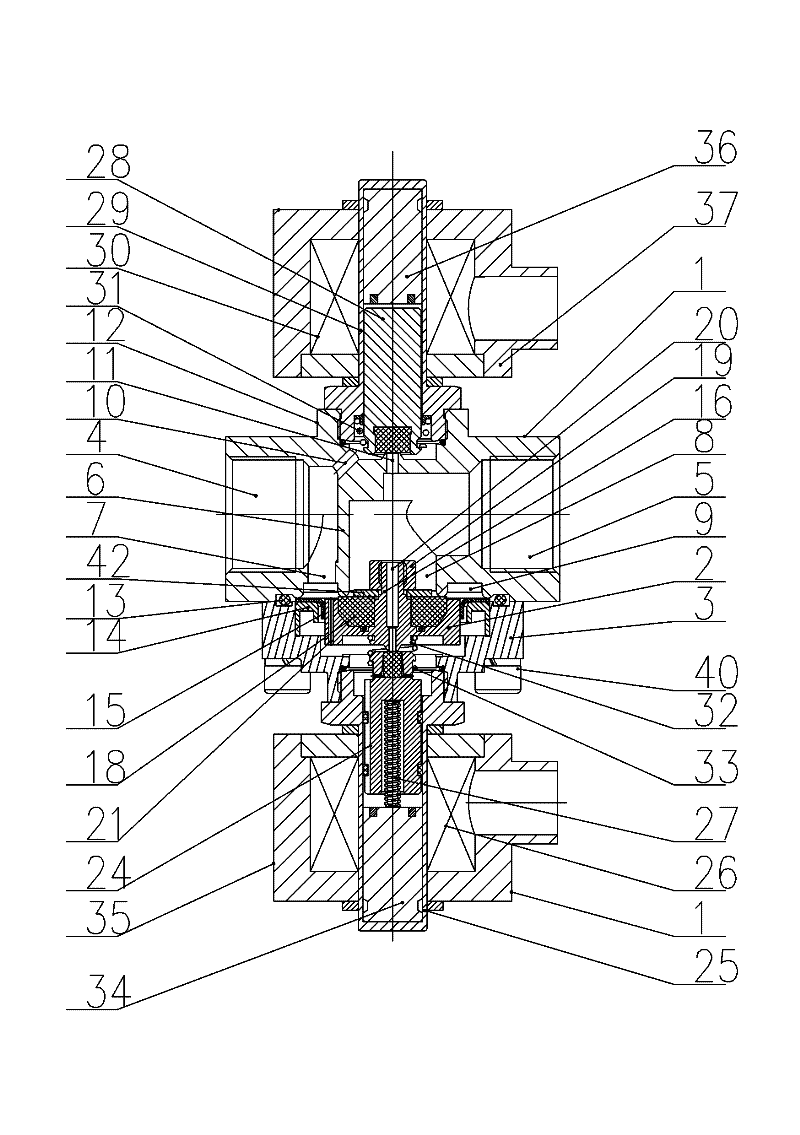

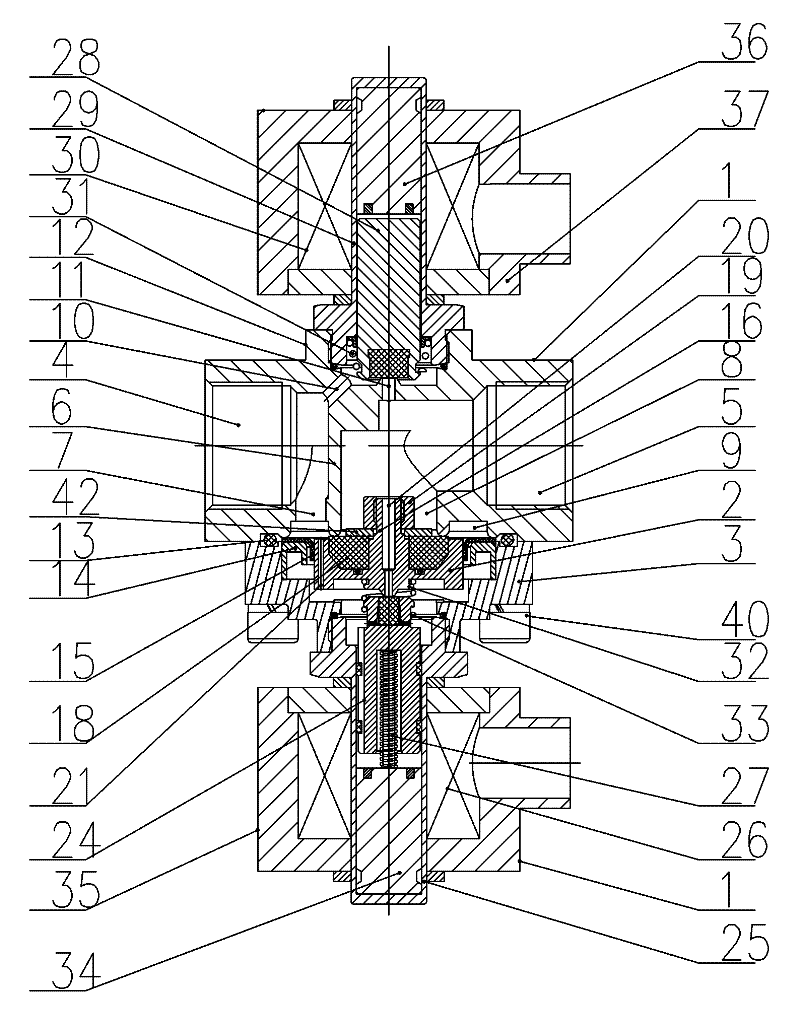

[0014] Embodiment 1 of the natural gas solenoid valve of the present invention, as figure 1 As shown, it consists of a valve body 1, a valve core assembly, a valve disc 2 and a valve cover 3 covering the outside of the valve disc 2. The valve body 1 is a cylindrical structure with two ends open, and one end of the valve body 1 has an inlet section 4 , the other end has an outlet section 5, the valve body 1 has a partition plate 6 for separating the inlet section 4 and the outlet section 5, the outer peripheral surface of the valve body 1 has corresponding first and second planes, and the first plane has The main valve channel and the main valve channel include a first through hole 7 and a second through hole 8 communicating with the inlet and outlet of the valve body respectively, and the outer circumference of the second through hole 8 on the valve body 1 has a The through first annular groove 9; there is an auxiliary valve channel on the second plane, the auxiliary valve cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com