Engine cylinder cover for combustion development

A technology for engine cylinders and cylinder heads, which is applied to engine components, machines/engines, and engine sealing devices. Mutual leakage, error elimination and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

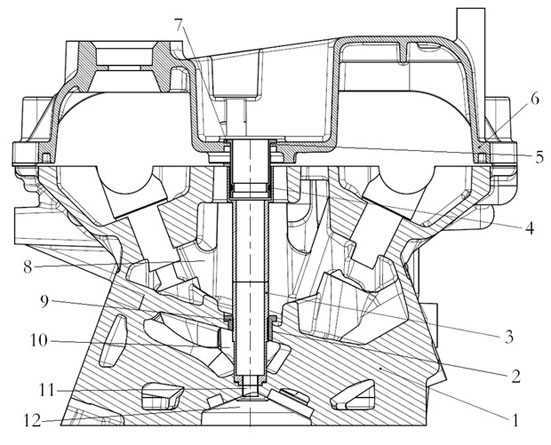

[0018] Such as Figure 1 to Figure 4 As shown, the engine cylinder head used for combustion development includes a cylinder head 1 and a cylinder cover 6 fixed on the top thereof, and a spark plug hole, a sand outlet process hole, an oil return chamber 8 and a cooling water channel 10 are opened on the cylinder head 1, A combustion chamber 12 is opened at the bottom of the cylinder head 1 .

[0019] A first installation hole 2 and a second installation hole 11 are opened on the cylinder head 1. The first installation hole 2 is located between the spark plug hole and the sand production hole, and connects the oil return chamber 8 with the cooling water channel 10. The axis line Near the center of the combustion chamber 12; the second installation hole 11 is a stepped hole, which communicates the cooling water channel 10 with the combustion chamber 12, and the first installation hole 2 and the second installation hole 11 are coaxial. An outer copper sheath 9 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com