Construction method of overlong and superhigh single-side fair-faced concrete wall

A technology for facing concrete and construction methods, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve the problems of easy deviation of the horizontal straightness of the formwork, horizontal open seam strips and pull bolts It is difficult to control the straightness of the hole, and the verticality of the formwork is prone to deviation, so as to ensure the installation quality and reduce the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

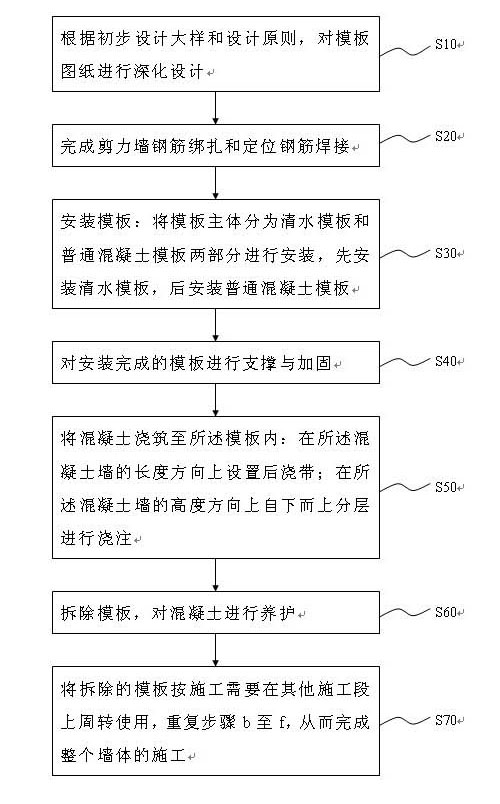

[0042] Such as figure 1 Shown, it is a kind of embodiment flow chart of the construction method of clear water facing concrete wall of the present invention.

[0043] S10, according to the preliminary design sample and design principles, carry out in-depth design on the formwork drawings.

[0044] According to the preliminary design samples and design principles provided by the design unit, carry out detailed design on the formwork drawings. According to the principle of symmetry and centering of the building, the detailed design must consider the specifications of the formwork used, the division of construction sections, the construction joints, the setting of post-pouring belts, the layout of open joints and the bolt holes, etc. It can only be implemented after being reviewed and approved by the teacher.

[0045] S20, completing the binding of the shear wall rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com