Method for rapidly determining welding parameter of electron beam

A technology of electron beam welding and parameters, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of hindering the popularization and application of electron beam welding technology, difficulty, long cycle, etc., to shorten the product delivery cycle, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

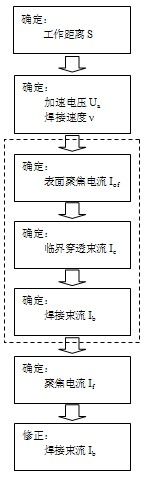

[0024] A method for quickly determining electron beam welding parameters such as figure 1 shown, including the following steps:

[0025] Step 1: Determine the welding working distance S. The electron beam is focused by the electromagnetic coil, and its working distance S determines the size of the focusing current, and the working distance can be freely determined within a certain range. In order to ensure the rapid portability of welding parameters, the working distance of the welding process test piece should be the same as that of the welding workpiece. In addition, the material, state and thickness of the process test piece used to explore the welding parameters before welding the workpiece should be the same as that of the workpiece to be welded.

[0026] The second step: select the acceleration voltage Ua and welding speed ν. The accelerating voltage and welding speed of the electron beam are related to factors such as equipment characteristics, performance, material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com