Easily-disassembled structure of umbrella handle

An umbrella handle and axial technology, applied in the field of easy dismantling structures of umbrella handles, can solve the problems of unsafe, inconvenient operation, and laborious disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

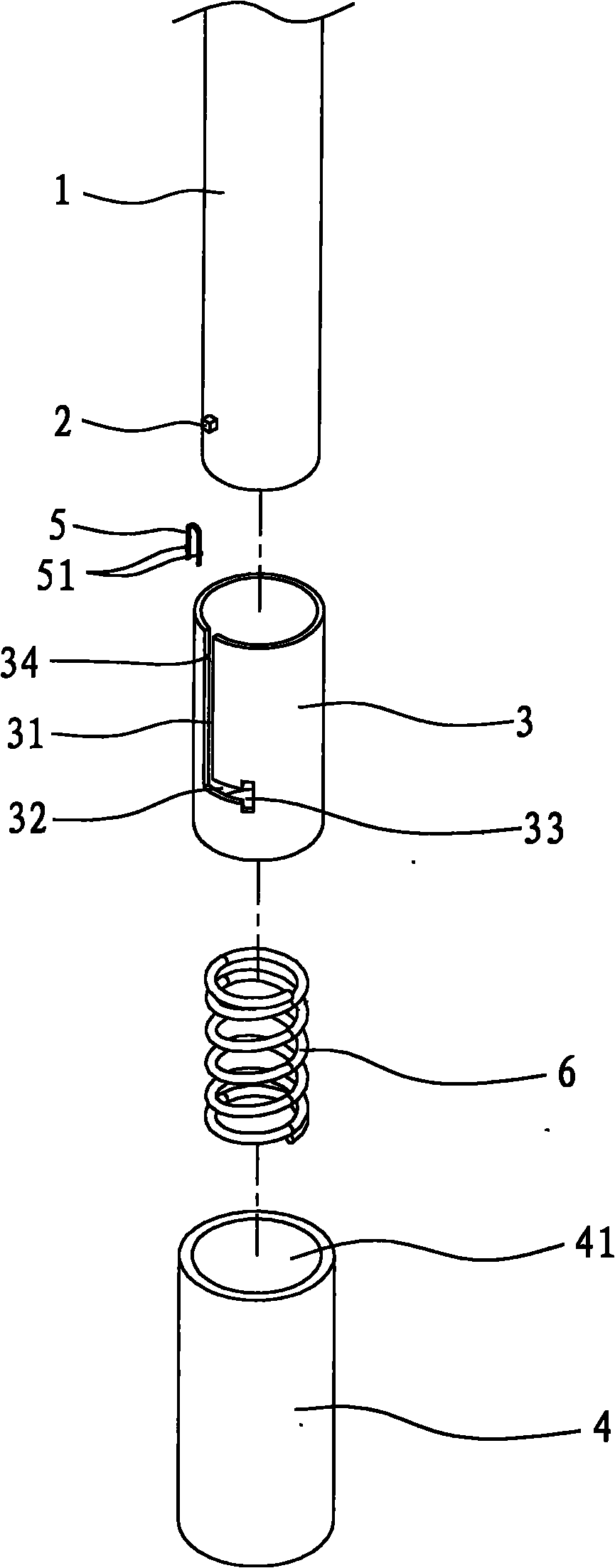

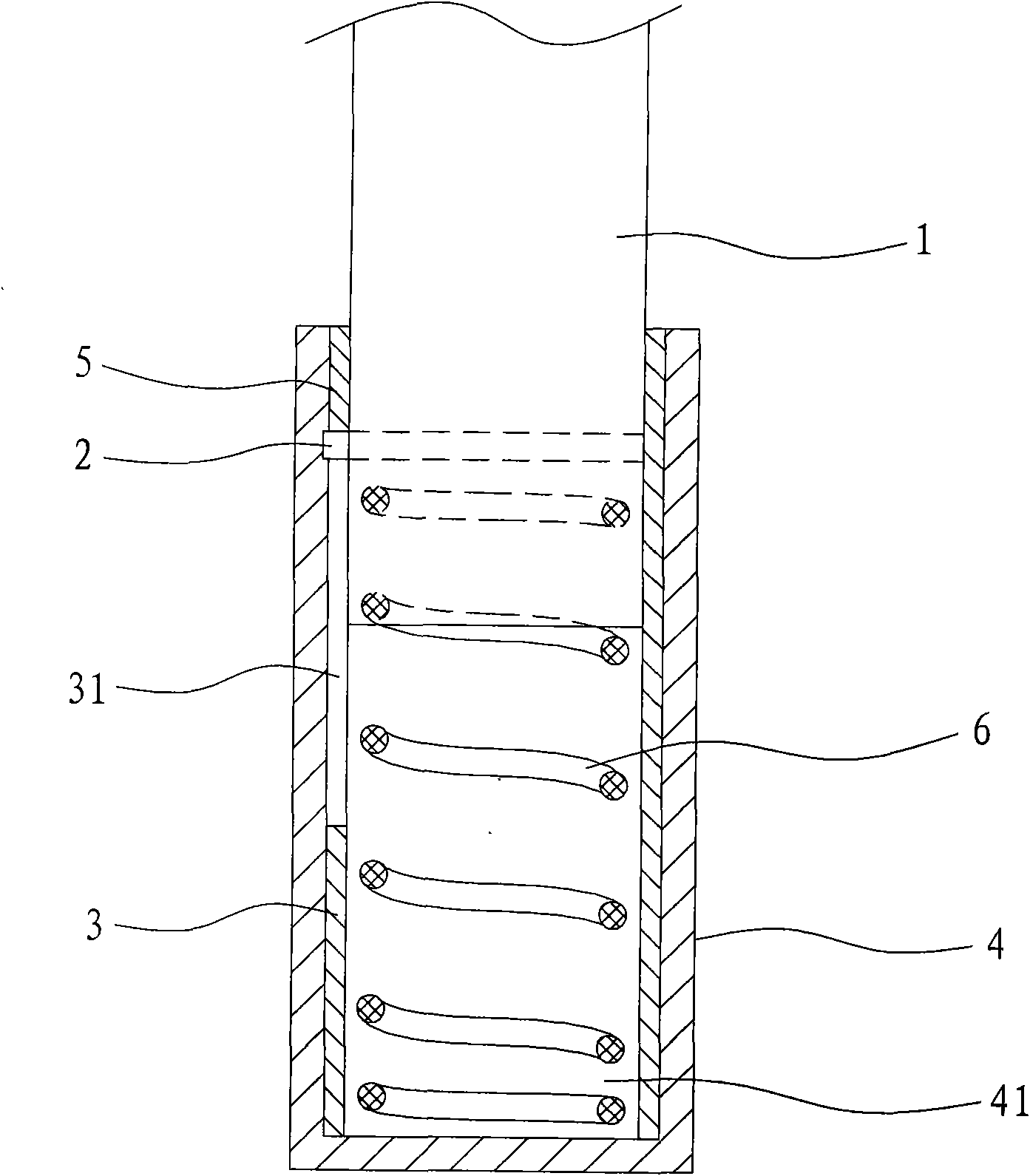

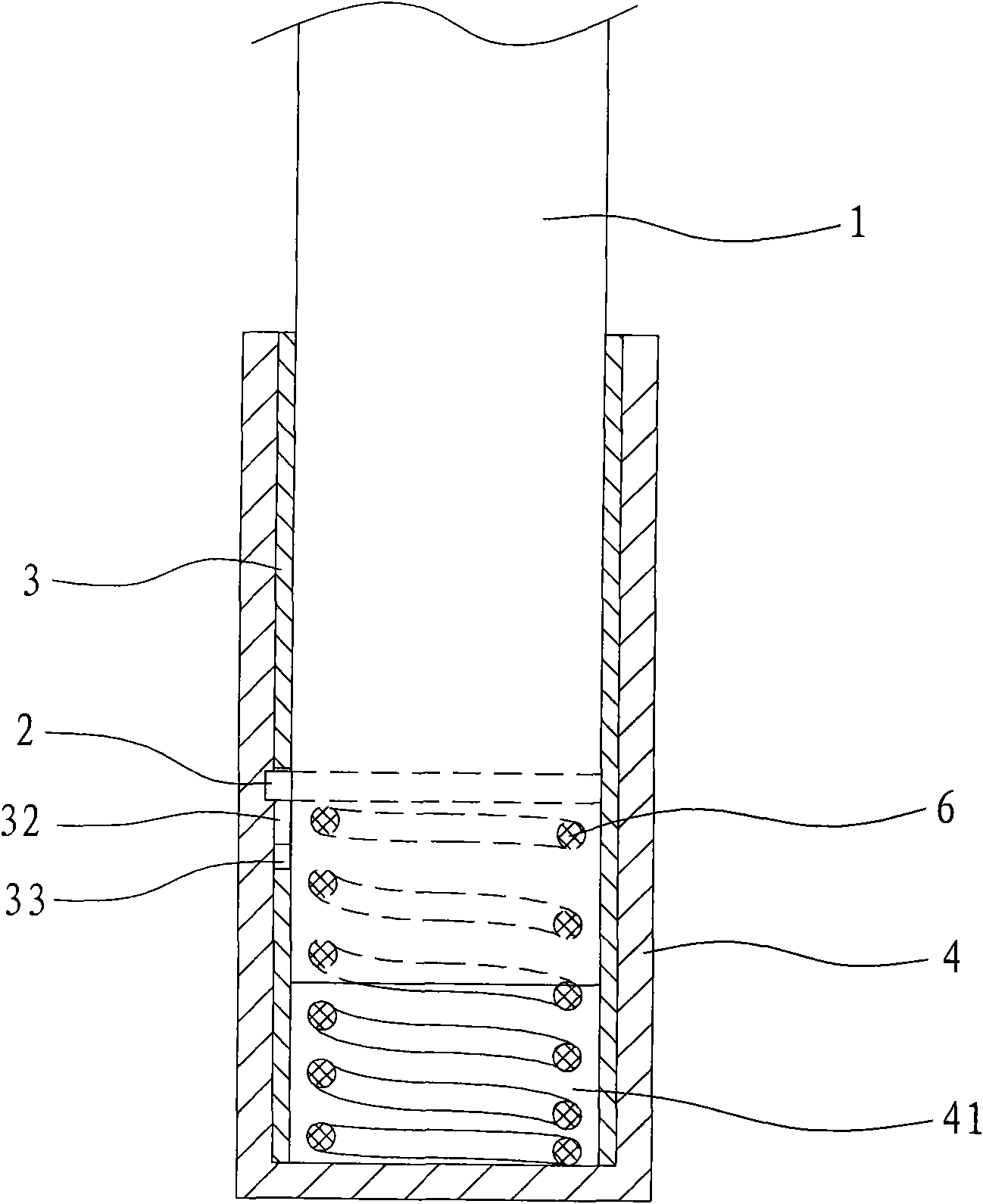

[0021] Such as figure 1 The easy-to-disassemble structure of the umbrella handle shown includes the positioning bead 2, the spring 6 and the inner sleeve 3. The positioning bead 2 is fixed on the lower end of the umbrella stick 1 (it can be integrally formed on the umbrella stick 1, or it can be separated and fixed after forming), the inner sleeve 3 is fixed in the installation hole of the umbrella handle 4, the inner sleeve 3 There is an axial insertion hole 41 for inserting the middle rod 1 of the umbrella, and the side wall of the axial insertion hole 41 is formed with an axial side groove 31 for the positioning beads 2 to slide into with the insertion of the middle rod 1 of the umbrella, and for positioning beads 2 The radial sliding groove 32 that rotates with the umbrella rod 1 and the axial positioning groove 33 for positioning after the positioning ball 2 rotates. One end of the radial sliding groove 32 is connected to the bottom end of the side groove 31 and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com