Real-time material distribution method in mechanical product assembling process

A technology for assembly process and mechanical products, applied in logistics, instruments, data processing applications, etc., can solve problems such as slow response speed, increased production cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] see figure 1 , through the daily operation plan to obtain all the parts information required for the day's production, and use the real-time material distribution method to calculate and obtain the daily distribution result set, and the warehousing and distribution department will distribute the materials required for production to the production line in a timely manner and in small batches according to the distribution list. At the same time, the MES system monitors the production line in real time, regularly judges whether the next batch of materials to be delivered is reasonable according to the actual production situation, and adjusts the delivery plan in time. In addition, if the production plan changes, the distribution plan will also change.

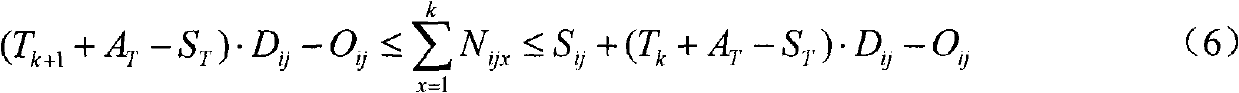

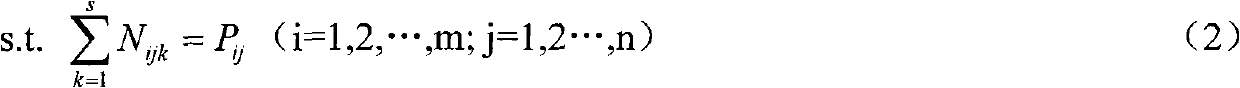

[0049] see figure 2 , the specific algorithm structure is as follows: use the product BOM model to calculate the parts information required by each station for production on the day, and comprehensively consider the start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com