Device for preparing multi interbedding rock-soil modeling materials

A model material and rock-soil technology, which is applied in the field of devices for preparing multi-interlayer rock-soil model materials, can solve problems such as the inability to simulate interlayer rock-soil bodies, and achieve the effects of avoiding discreteness, thickness adjustment, and easy thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

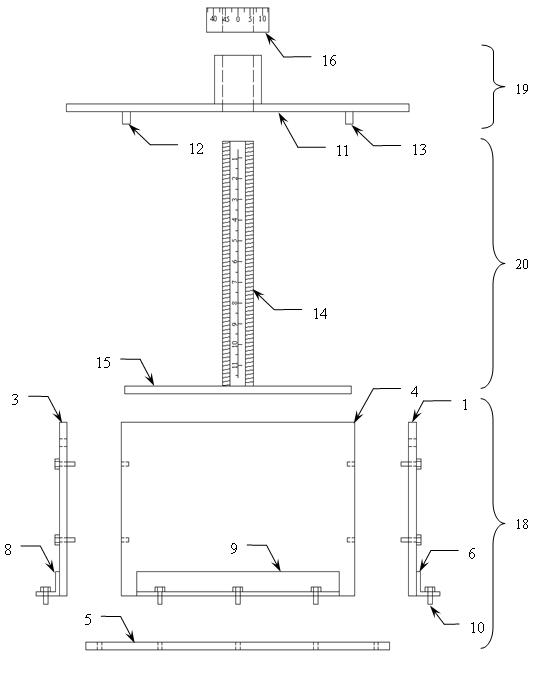

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

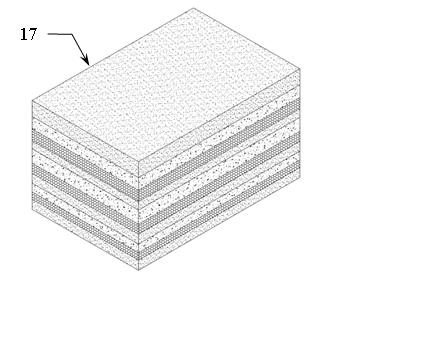

[0042] The basic idea of the present invention is to obtain multi-interlayer model material blocks 17 by uniformly laying a variety of similar materials layer by layer.

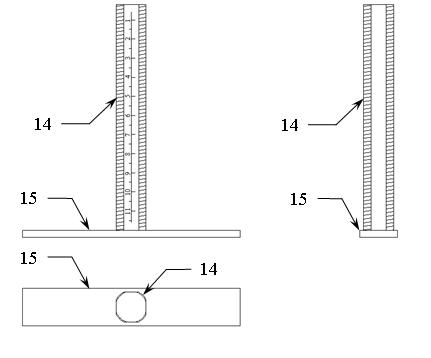

[0043] The main components of the device of the present invention include a material box 18 (connected and combined by the first side plate 1, the second side plate 2, the third side plate 3, the fourth side plate 4, the bottom plate 5 and some fastening bolts 10), Flat push plate 19 (connected and combined by the main frame 11 of the flat push plate and the first strip steel 12 and the second strip steel 13), T-shaped frame 20 (connected and combined by special bolts 14 and the third strip steel 15 ), the adjusting nut 16 is characterized in that: the special bolt 14 of the T-shaped frame 20 passes through the square hole in the middle of the main frame 11 of the flat push plate and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com