Inner leak detection device of heat exchanger

A technology of heat exchanger and detection device, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of inconvenient operation, low leak detection efficiency and complex structure, etc. Achieve the effect of convenient use, simple structure and high leak detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

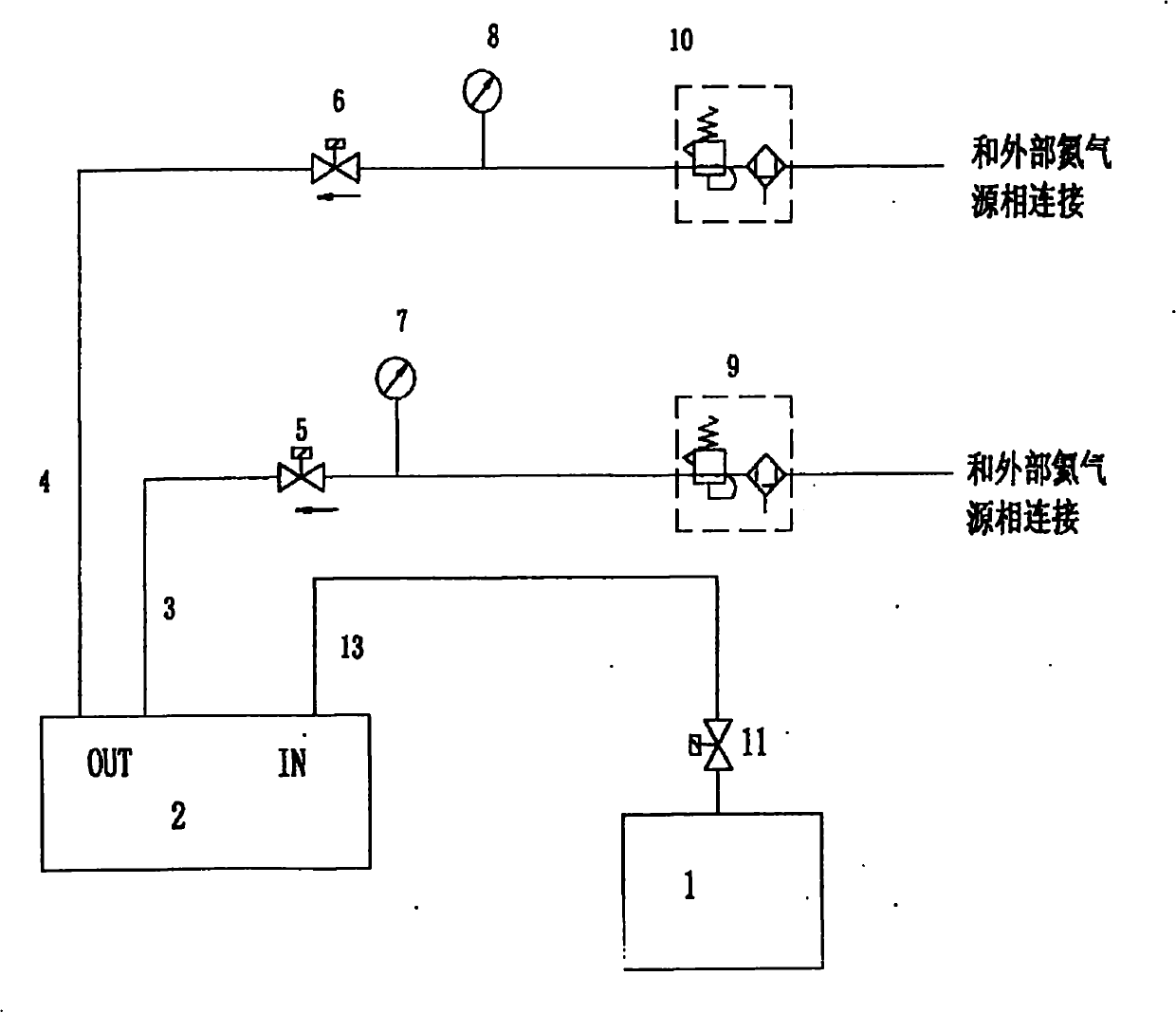

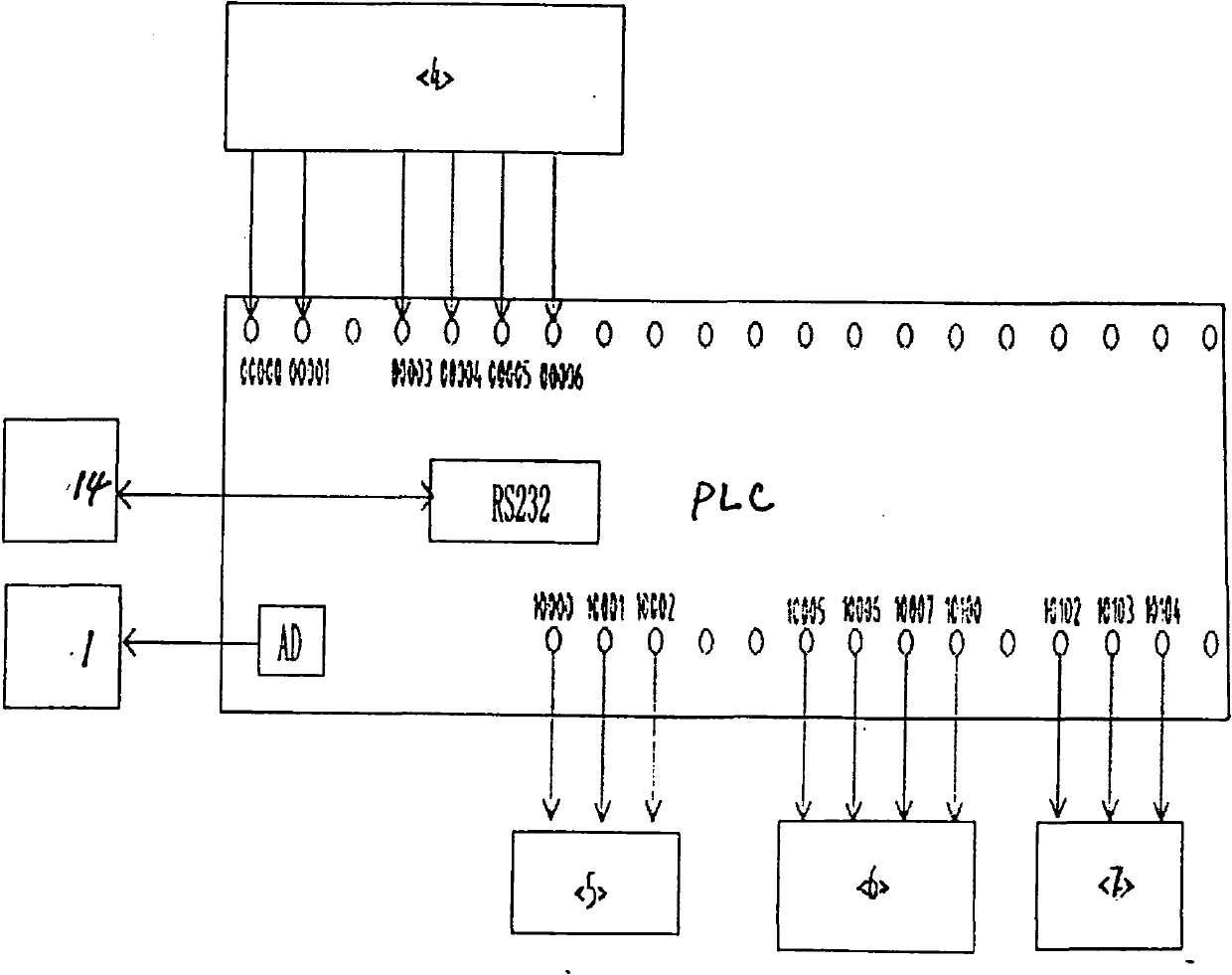

[0016] In the heat exchanger internal leakage detection device of the present invention, the helium mass spectrometer leak detector 1 is connected to the IN port of the heat exchanger 2 through the first pipeline 13, and the helium-filled tube 3 and the nitrogen-filled tube 4 are respectively connected to the two ends of the heat exchanger 2. OUT port connection, the second solenoid valve 5, the first air pressure gauge 7, and the first pressure reducing valve 9 are located on the helium filling tube 3, and the third electromagnetic valve 6, the second air pressure gauge 8, and the second pressure reducing valve 10 are located on the nitrogen filling pipe. Tube 4 on. The two OUT ports are connected in parallel, and communicate with the IN port through pipes.

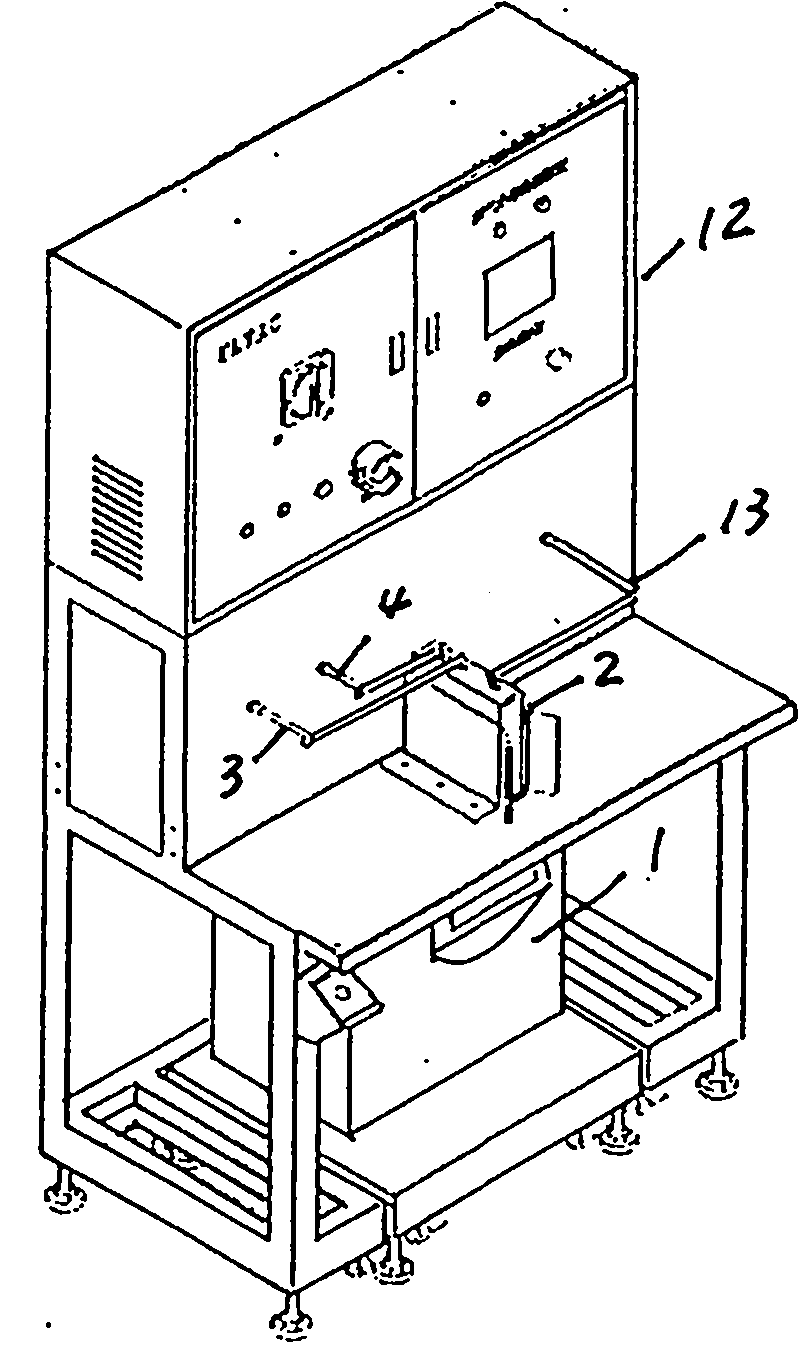

[0017] The electric control system cabinet 12 of the present invention is installed on the top of the frame, on the left side of the electric control system cabinet, a manual selection switch, a start switch, and an emer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com