Concrete sample curing room

A technology for concrete specimens and curing chambers, applied to ceramic molding machines, manufacturing tools, etc., can solve the problems that cannot be effectively realized and trouble concrete testers, and achieve the effect of uniform temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

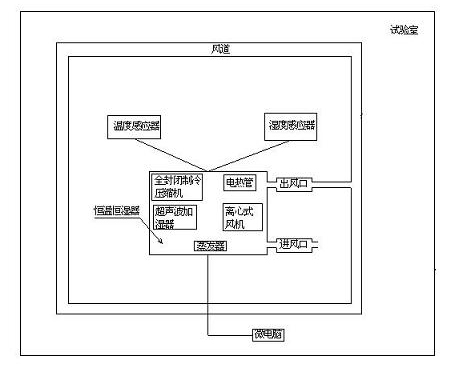

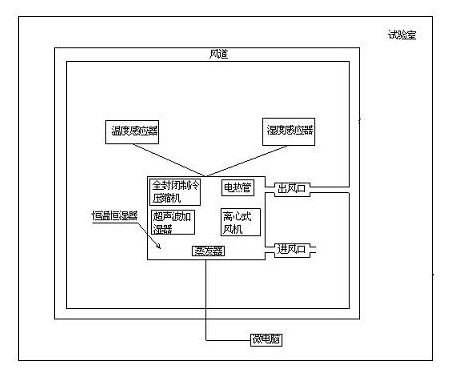

Image

Examples

specific Embodiment approach

[0023] (1) Temperature control:

[0024] In summer, when the temperature in the constant temperature and humidity chamber rises to 22°C, the fully enclosed refrigeration compressor unit starts to work, and the fan blows out cold air (the cooling principle of the air conditioner); when the temperature drops to 20°C, the machine stops working, and in winter, the constant temperature When the temperature in the humidity chamber is lower than 18°C, the electric heating tube starts to work, and when the temperature rises to 20°C, the machine stops working.

[0025] ( 2) Humidity control:

[0026] When the humidity in the constant temperature and humidity chamber drops below 55%, the temperature and humidity sensor sends the 55% humidity signal to the microcomputer automatic control panel, starts the ultrasonic humidifier and centrifugal fan, and starts humidification. The wind sent by the centrifugal fan blows the mist from the ultrasonic humidifier to all parts of the constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com