Split-type nanometer fibre solid-phase extraction column and application thereof

A solid-phase extraction column and nanofiber technology, which is applied in separation methods, solid adsorbent liquid separation, chemical instruments and methods, etc., can solve the problems of cumbersome solid-phase extraction operations, insignificant enrichment effects, and long operation time. To achieve the effect of easy mass production, reducing the amount of desorbent, and efficient adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

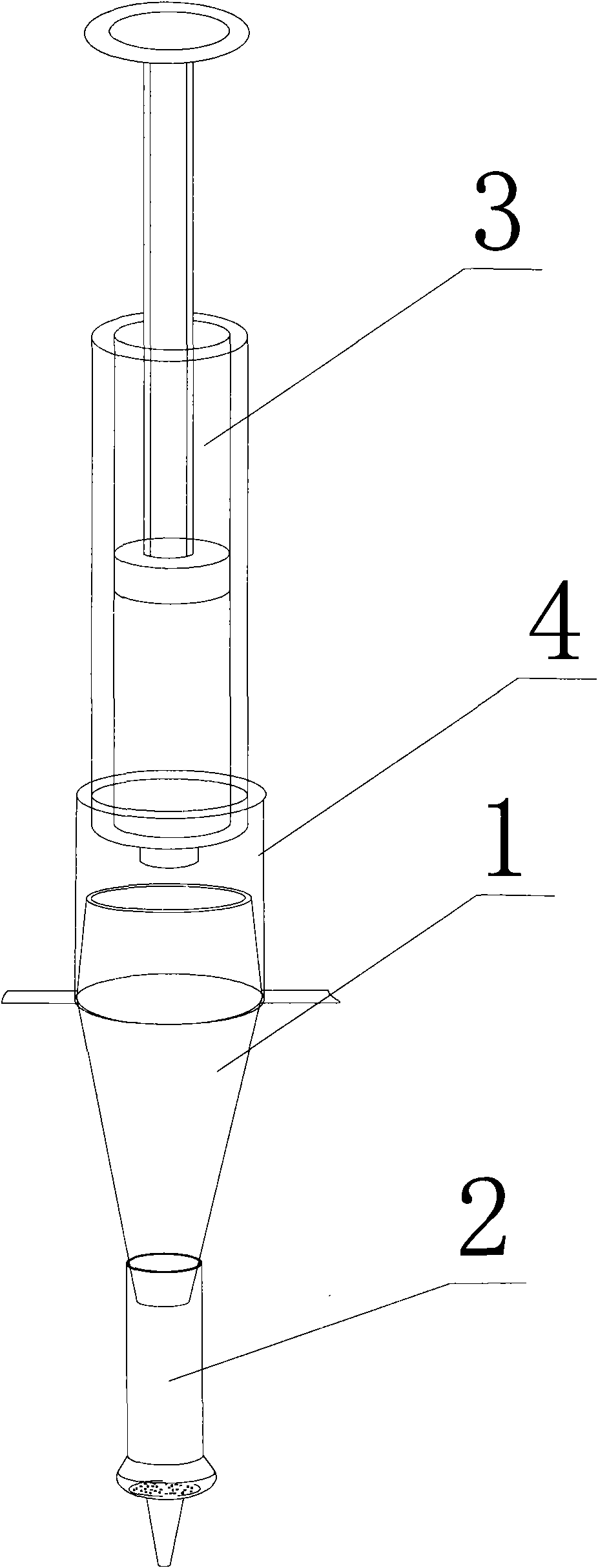

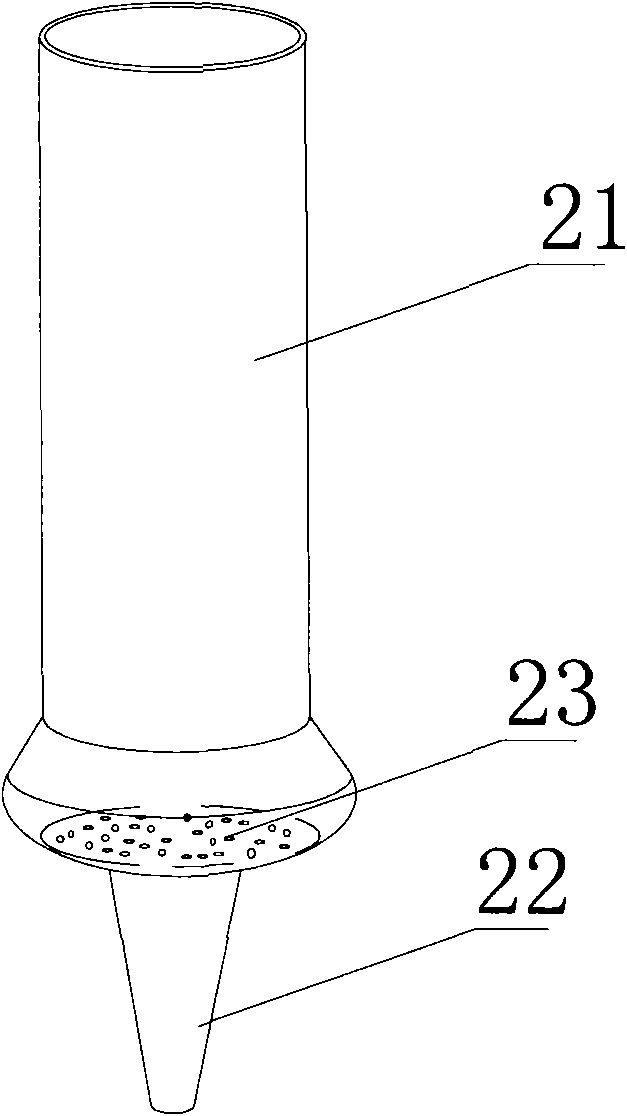

[0024] Example Figure 1~4 As shown, the split nanofiber solid phase extraction column includes a sample storage tube 1, the lower end of the sample storage tube 1 is sleeved with a fiber filling tube 2, and the inside of the fiber filling tube 2 is filled with nanofibers as a column filler. The sample storage tube 1 includes upper and lower tapered tubes 11, 12, and the upper and lower tapered tubes 11, 12 are connected into one body through the larger ends of the tapered tubes. The fiber filling tube 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com