Anti-static device and method for repairing PDP module

An anti-static, modular technology, applied in the direction of static electricity, electrical components, etc., can solve the problems of delayed failure of devices, immediate failure of devices, etc., and achieve the effects of preventing leakage backflow, reducing action time, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

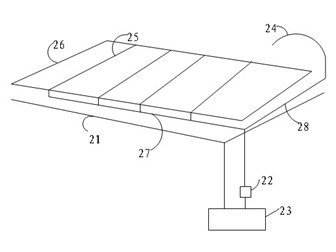

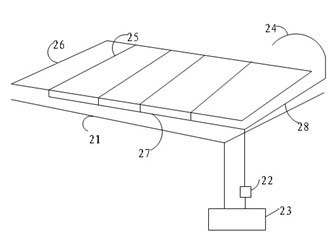

[0022] An anti-static device for PDP module repair, which is divided into three parts: the anti-static grounding system for the display screen, the anti-static grounding system for the backplane and PCB, and the anti-static grounding system for the human body. figure 1 Shown:

[0023] A horizontal screen support surface 26 is used as a support for display module maintenance, and a conductive cloth 25, a first static grounding wire 27, a grounding resistor 22 and a ground 23 are used to form an anti-static grounding system for a display screen. The conductive cloth 25 has extremely low on-resistance, and it is a good conductor of static charges. The connection between the conductive cloth 25 and the first electrostatic grounding wire 27 is pasted on the peeled bare wire of the first electrostatic grounding wire 27 by the conductive cloth 25, and then wrapped around their connection points with a wire to realize a fast and reliable connection. It is even possible to use an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com