Preparation method of negative plate of chemical battery

A chemical battery and negative electrode technology, applied in the direction of alkaline battery electrodes, etc., can solve the problems of low automation, good flexibility of the electrode, and high automation, so as to improve the utilization rate, increase the pass rate, and reduce the tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

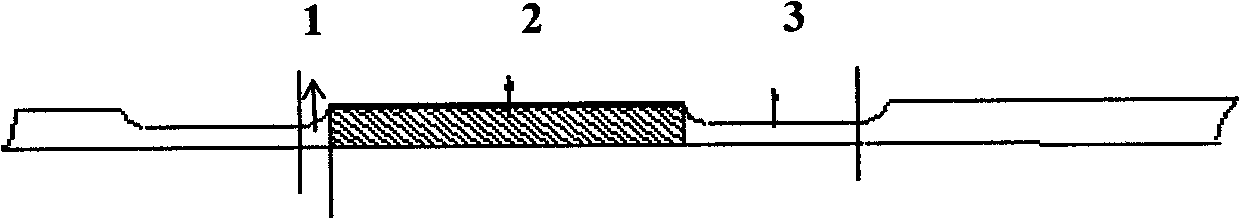

[0026] Such as figure 1 The structure of the AA2500HC battery shown is divided into negative electrode scraping surface 1, negative electrode front section 2, positive electrode tail end 3, winding needle 4, separator 5, and positive electrode front section 6. The positive electrode, the separator, and the negative electrode are stacked and wound on each other. The innermost circle of the negative electrode is close to the winding core, and the last circle is close to the steel shell.

[0027] The production method of the positive plate: the commercial spherical nickel hydroxide and cobalt powder are mixed in a ratio of 95:5, mixed evenly, then filled into the foamed nickel, rolled and cut into 95mm×43mm×0.68mm , The total amount of active material contained in the positive electrode is 10.0g.

[0028] The preparation of the negative electrode sheet includes slurry mixing, continuous sizing, drying, rolling, automatic welding of tabs, automatic gluing, and cutting.

[0029] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com