High-fuel-efficiency internal combustion engine

A fuel-efficient, internal-combustion engine technology for use in internal-combustion piston engines, combustion engines, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

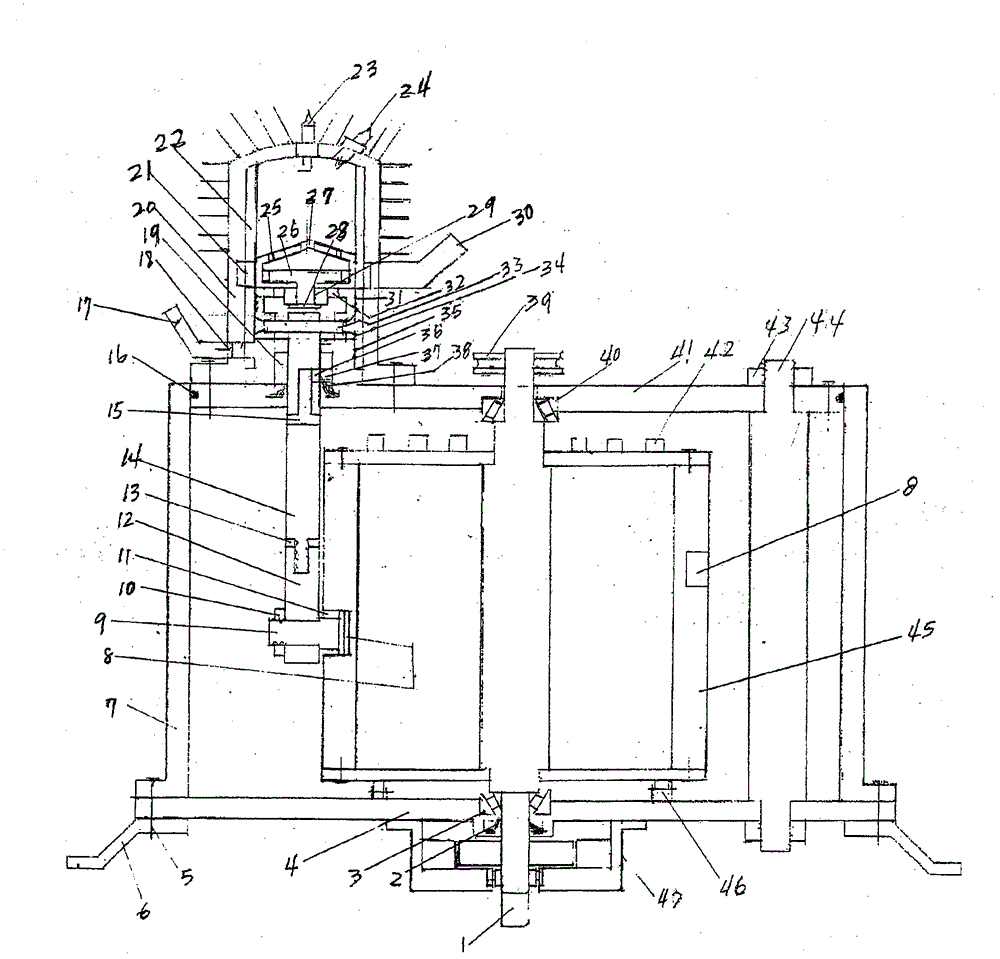

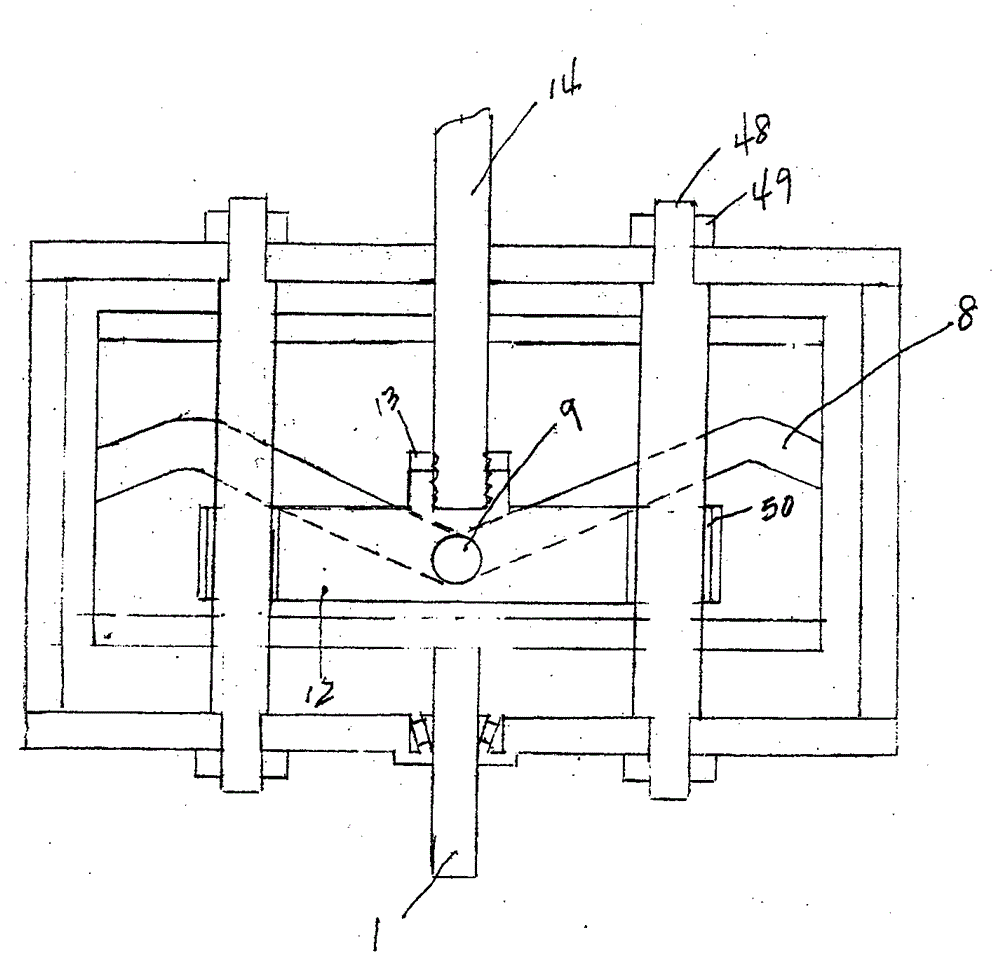

[0028] The specific components and their relationships of an embodiment of the internal combustion engine of the present invention will be described in detail below, and then its working principle will be described in detail, and finally its fuel efficiency will be analyzed schematically.

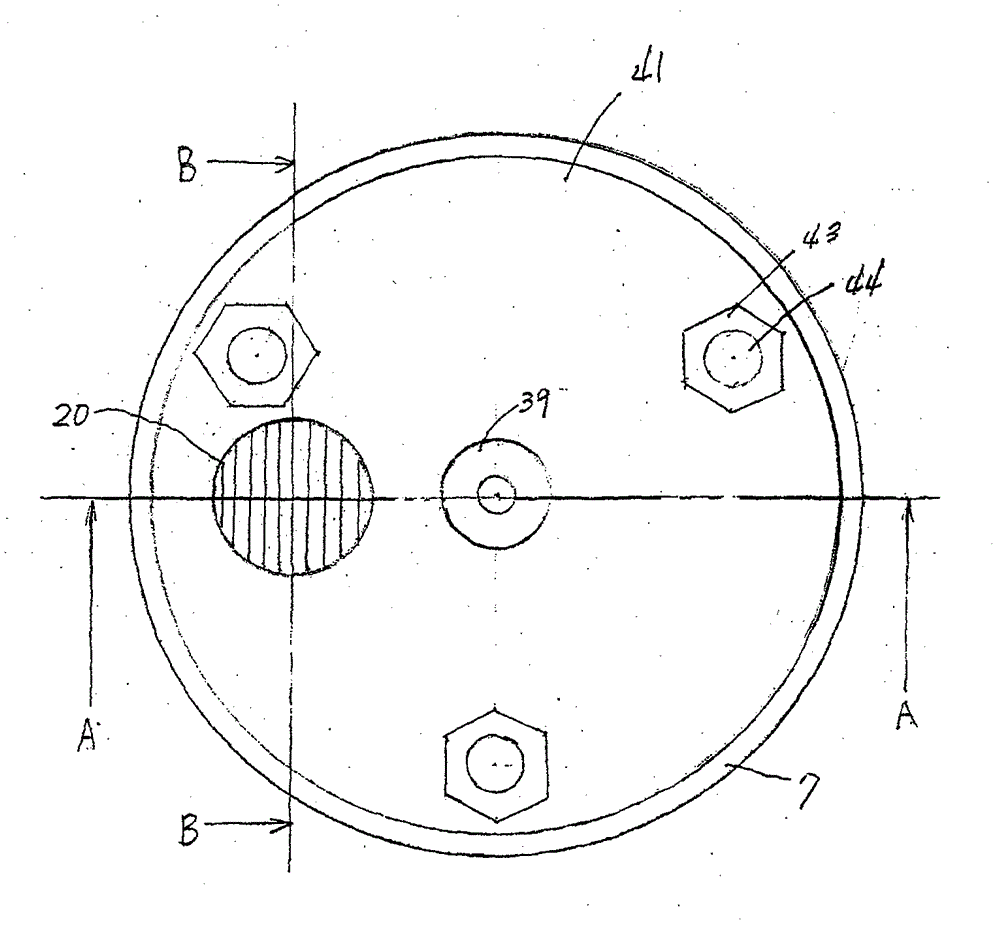

[0029] like figure 1 and figure 2 As shown, the high fuel efficiency internal combustion engine of the present invention includes: a cylinder 20 , a cam (flywheel) 45 , a central shaft 1 , a motor 47 that also functions as a generator, an outer cover 7 and a foot 6 .

[0030]A spark plug 23 and an oil injector 24 are installed on the cylinder head of the cylinder 20 . Piston 34 is arranged in cylinder 20, and inlet valve 26 is installed on piston 34, and the elasticity of spring 29 of valve 26 is weaker, and when non-explosive stroke, when piston 34 descends, it is difficult to produce vacuum in the cylinder, and it is easy to start the engine; A piston upper cover, drilling holes on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com