Single movable arm forward six-bar linkage power quick-change operating device for loading machine

A working device and six-link technology, which is applied to mechanically driven excavators/dredgers, etc., can solve problems such as difficult implementation and complex design of forward-rotating six-links, so as to improve efficiency and enhance bending and torsion resistance , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

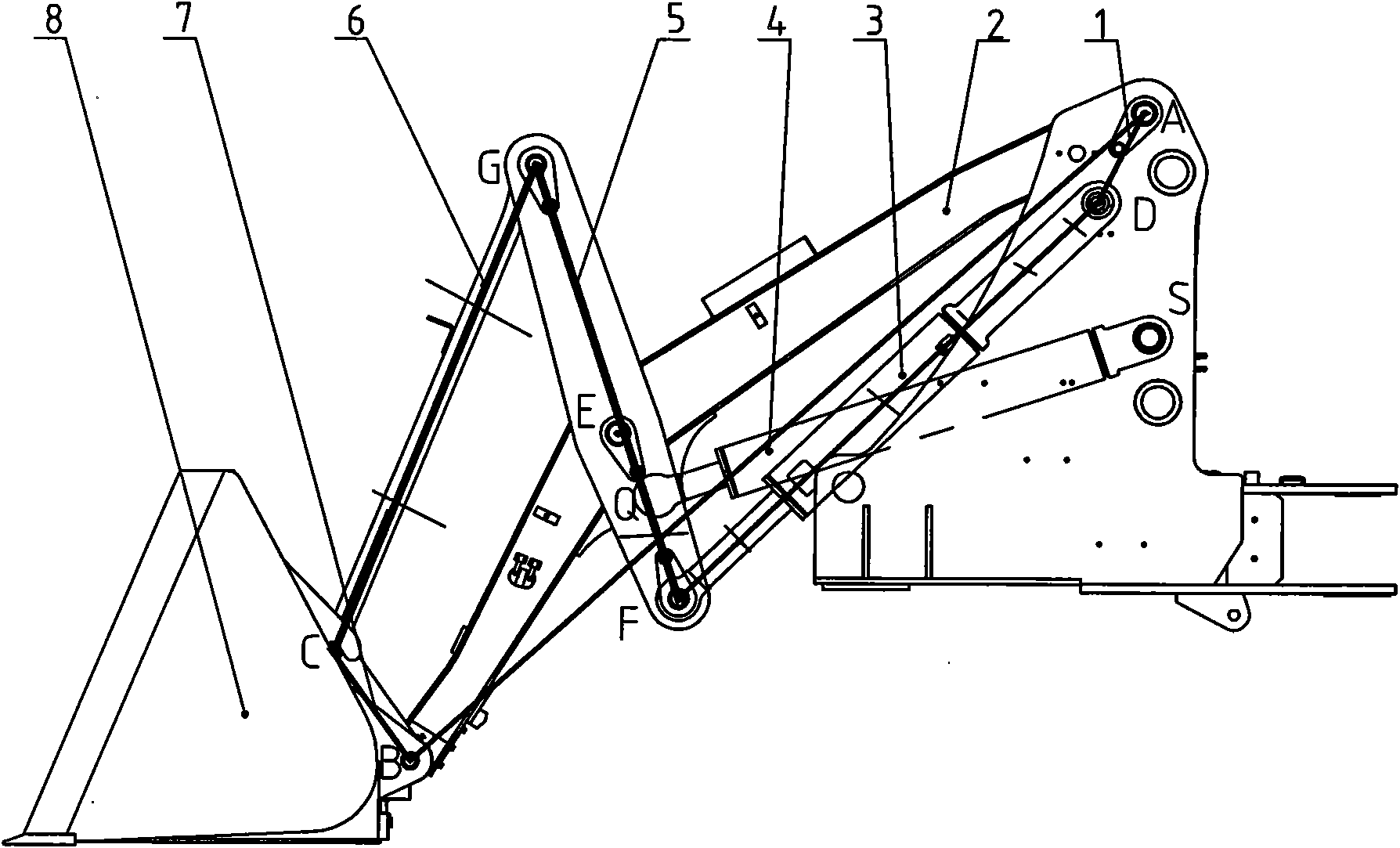

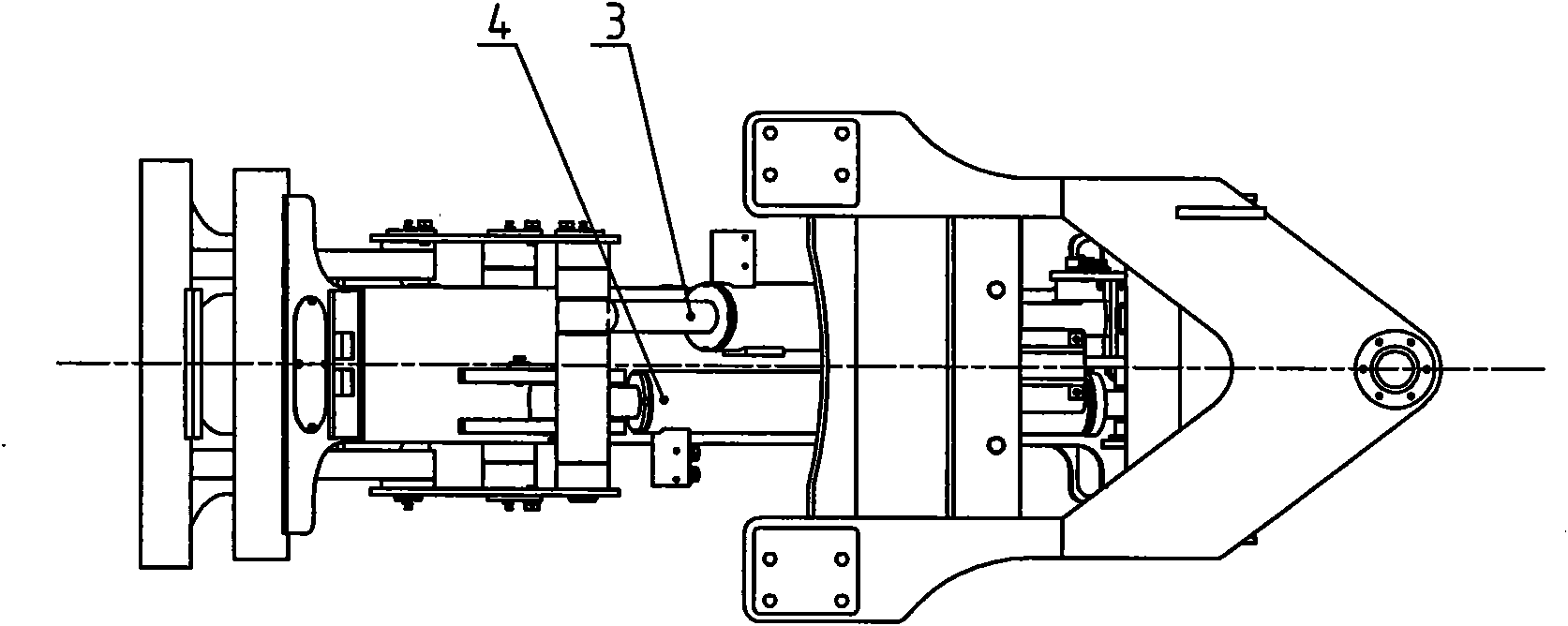

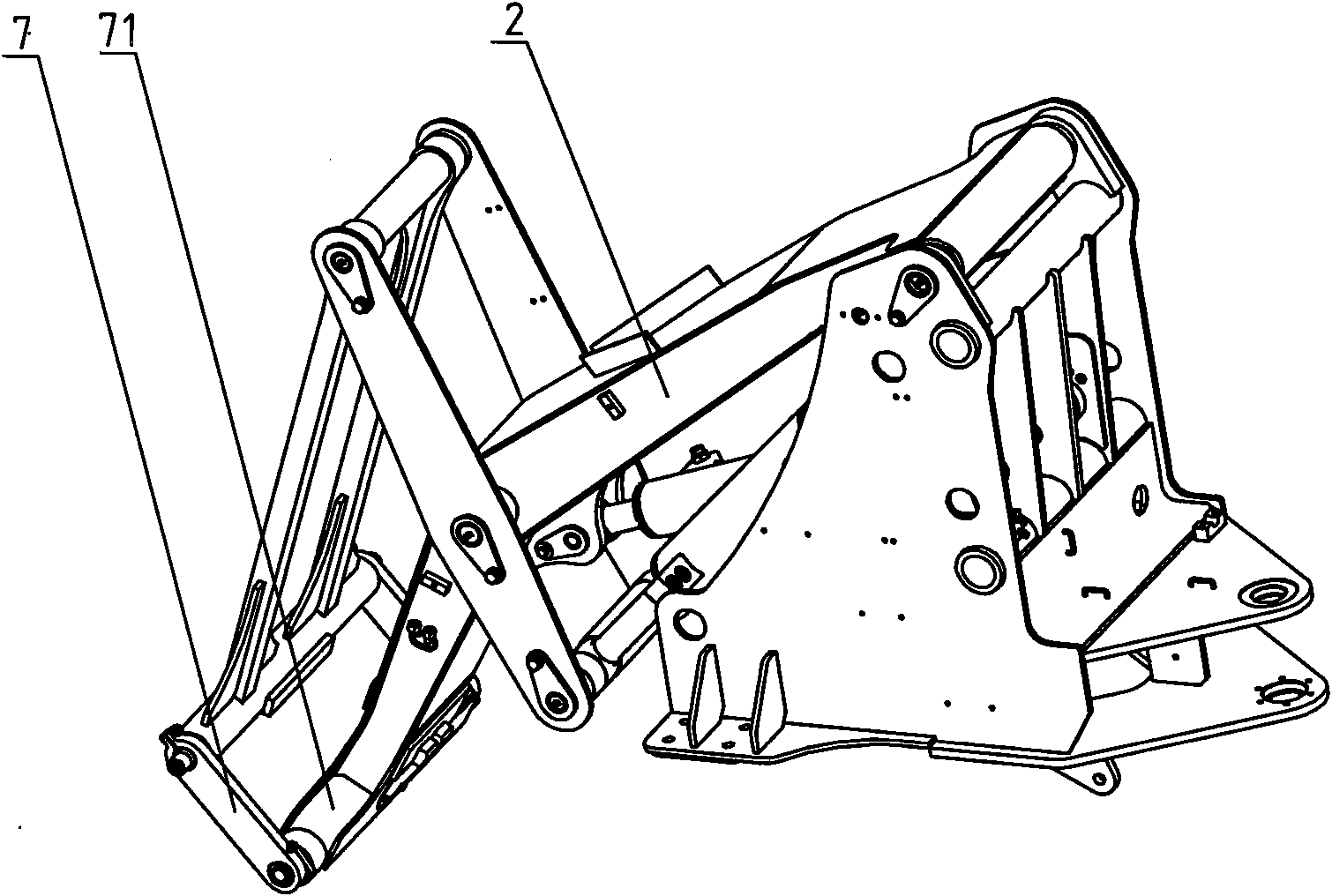

[0016] Such as Figure 1 ~ Figure 3 As shown, the present invention comprises a front frame 1, a boom 2, a bucket cylinder 3, a boom cylinder 4, a rocker 5, a pull rod 6, a quick change device 7 and an attachment 8, and the vehicle frame 1 is connected to one end of the boom 2 respectively. It is hinged at point A on the upper side of the vehicle frame 1 , is hinged at point D on the upper side of the vehicle frame 1 with one end of the bucket oil cylinder 3 , and is hinged at point S at the middle of the vehicle frame 1 with one end of the boom cylinder 4 . The middle part of the rocker arm 5 and the middle part of the boom 2 are hinged at point E, the two ends of the rocker arm 5 are respectively hinged with the other end of the bucket cylinder 3 and the end of the pull rod 6 at two points F and G, and the other end of the boom 2 is hinged with the quick change device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Telescopic length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com