Implantable corrosion-proof preformed pile for use in salt oil foundation and construction method thereof

A construction method and technology of prefabricated piles, which are applied in basic structure engineering, sheet pile walls, protection devices, etc., can solve the problems of high engineering cost and complicated construction process, and achieve the goal of overcoming high engineering cost, mature process method and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

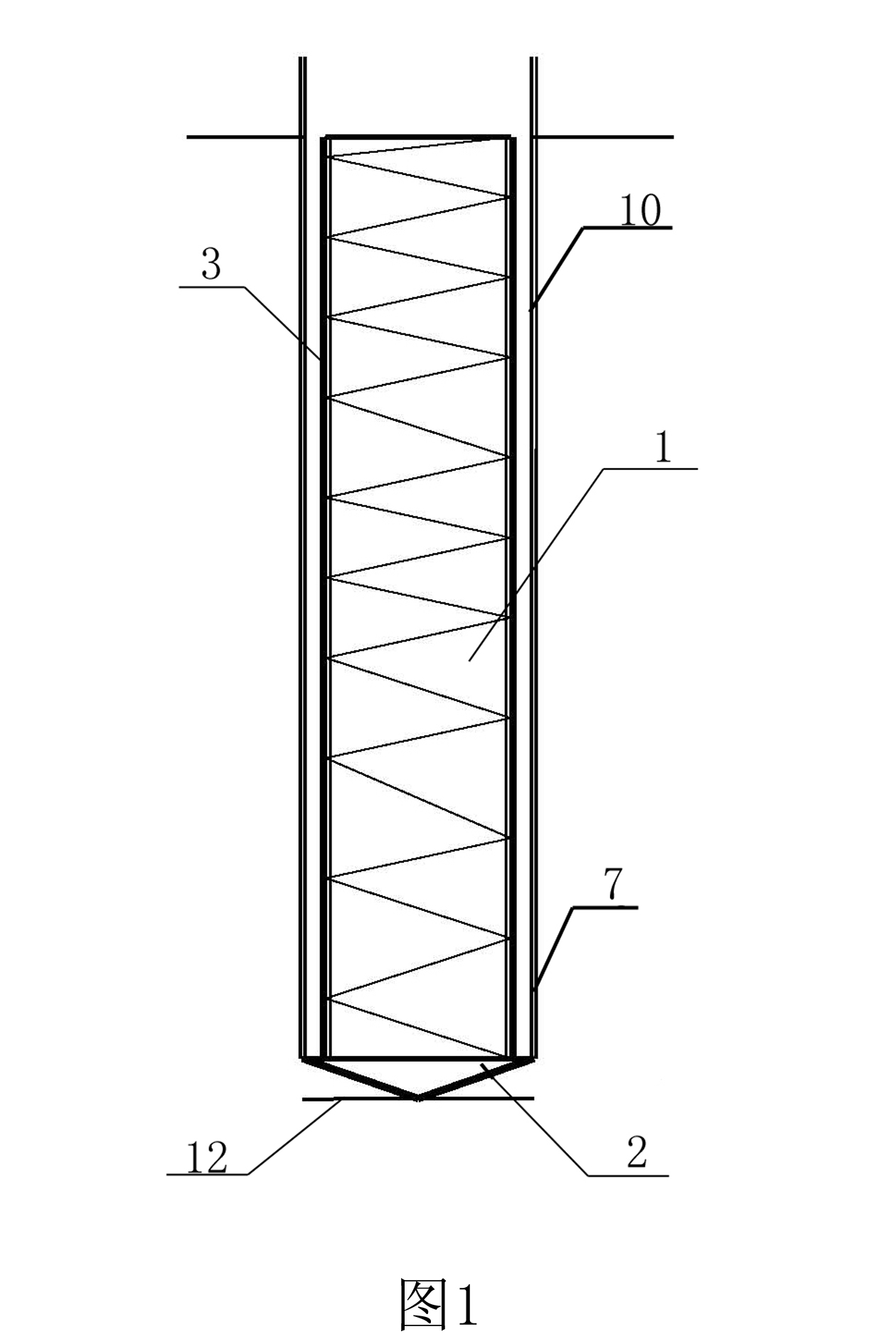

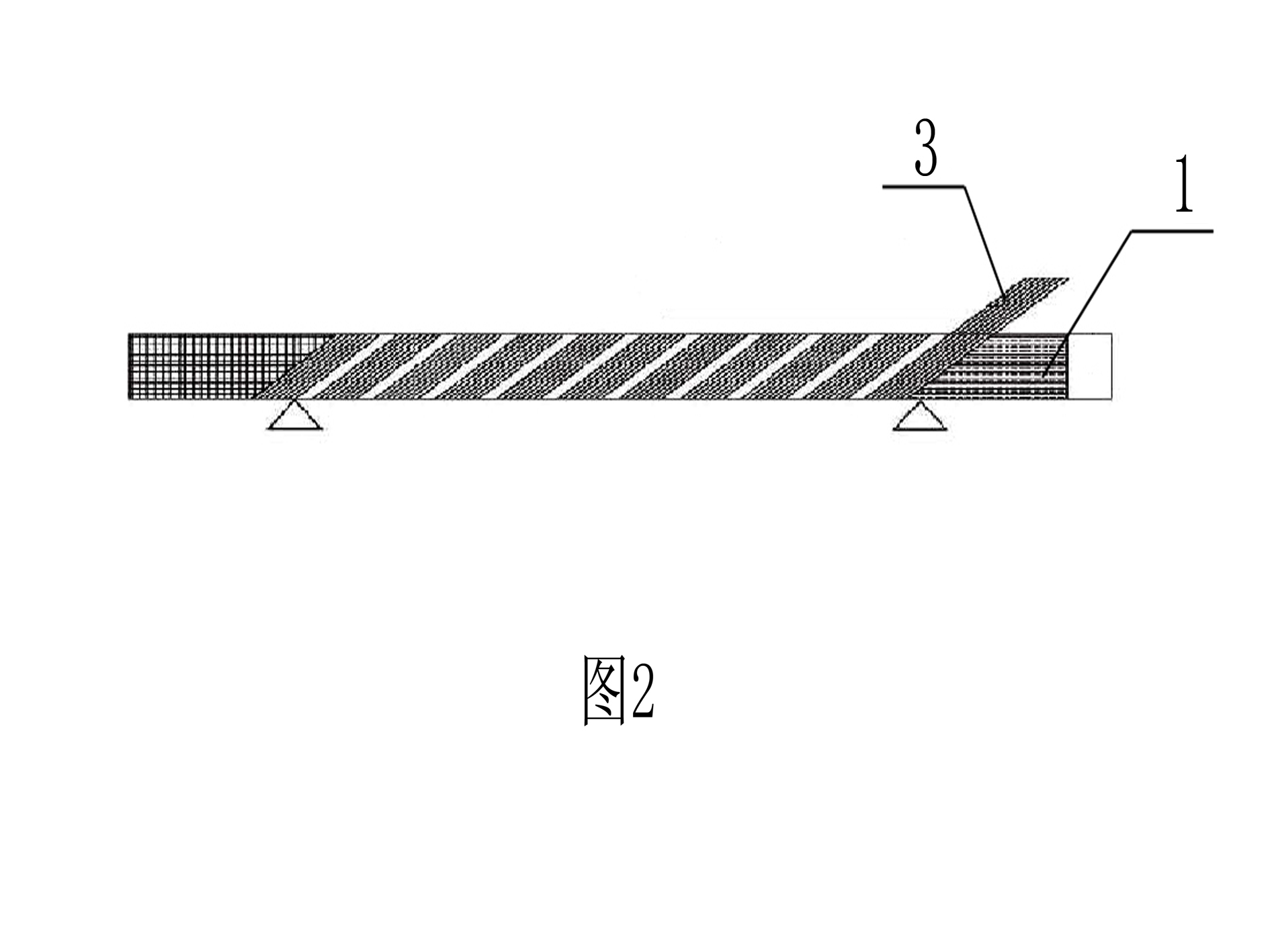

[0053] Examples see figure 1 As shown, an implanted anti-corrosion prefabricated pile applied in a saline soil foundation includes a prefabricated concrete pile body 1, the periphery of the pile body 1 is tightly wrapped with anti-corrosion cloth 3, and a steel pile is installed at the implanted end of the pile body Point 2, the steel pile point 2 is a conical welded on the lower surface of the base plate 2.2 formed by a group of rib plates 2.1, and a snap ring 2.3 is welded on the upper surface of the base plate, the inner diameter of the snap ring 2.3 is in line with the outer diameter of the pile body 1 The diameters are equal, and the bottom of the pile body is snapped into the snap ring 2.3, and the anti-corrosion cloth 3 is a geotextile made of anti-corrosion materials.

[0054] The outer surfaces of the pile body 1 and the anti-corrosion cloth 3 are all coated with anti-corrosion materials.

[0055] The cross section of the pile body 1 and the snap ring 2.3 is circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com