Method for preparing epoxidized natural rubber

A technology of natural rubber and epoxidation, which is applied in the field of ultrasonically accelerated epoxidation reaction to prepare epoxidized natural rubber, which can solve the problems that epoxidized natural rubber cannot achieve quality consistency, so as to ensure product quality and quality consistency , Excellent performance, suppress the effect of open loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

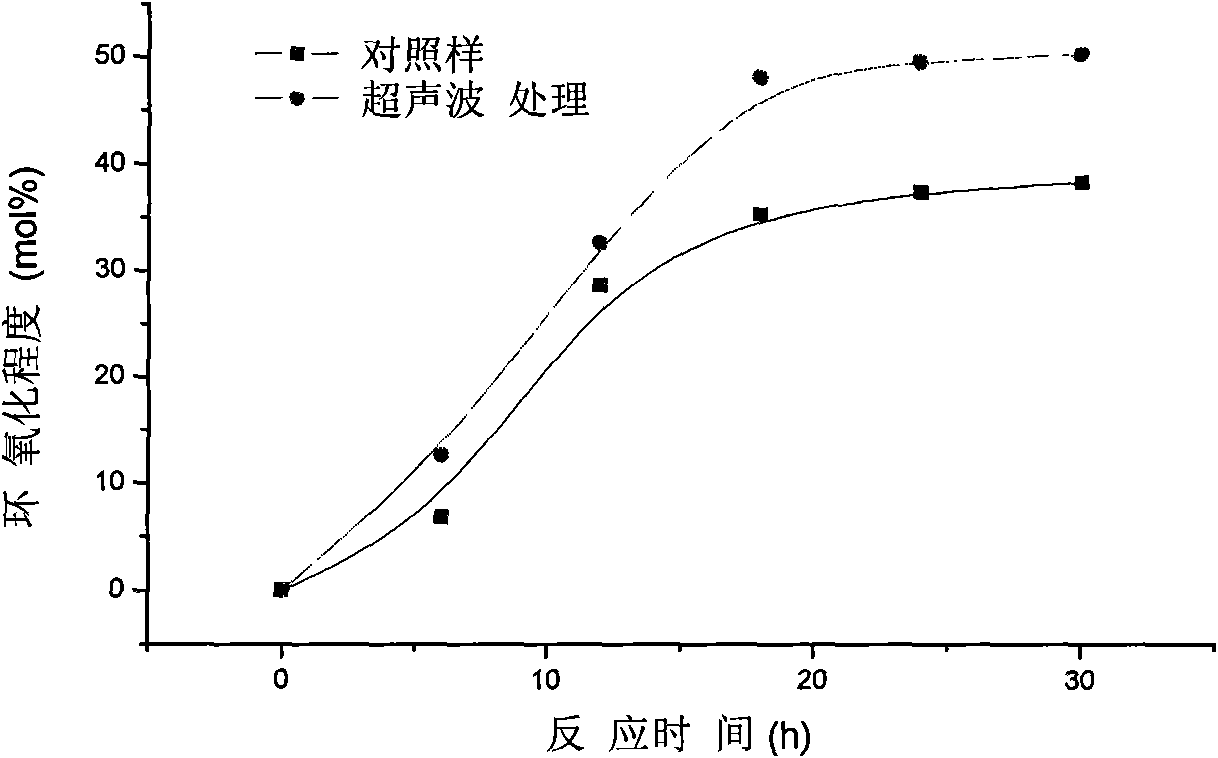

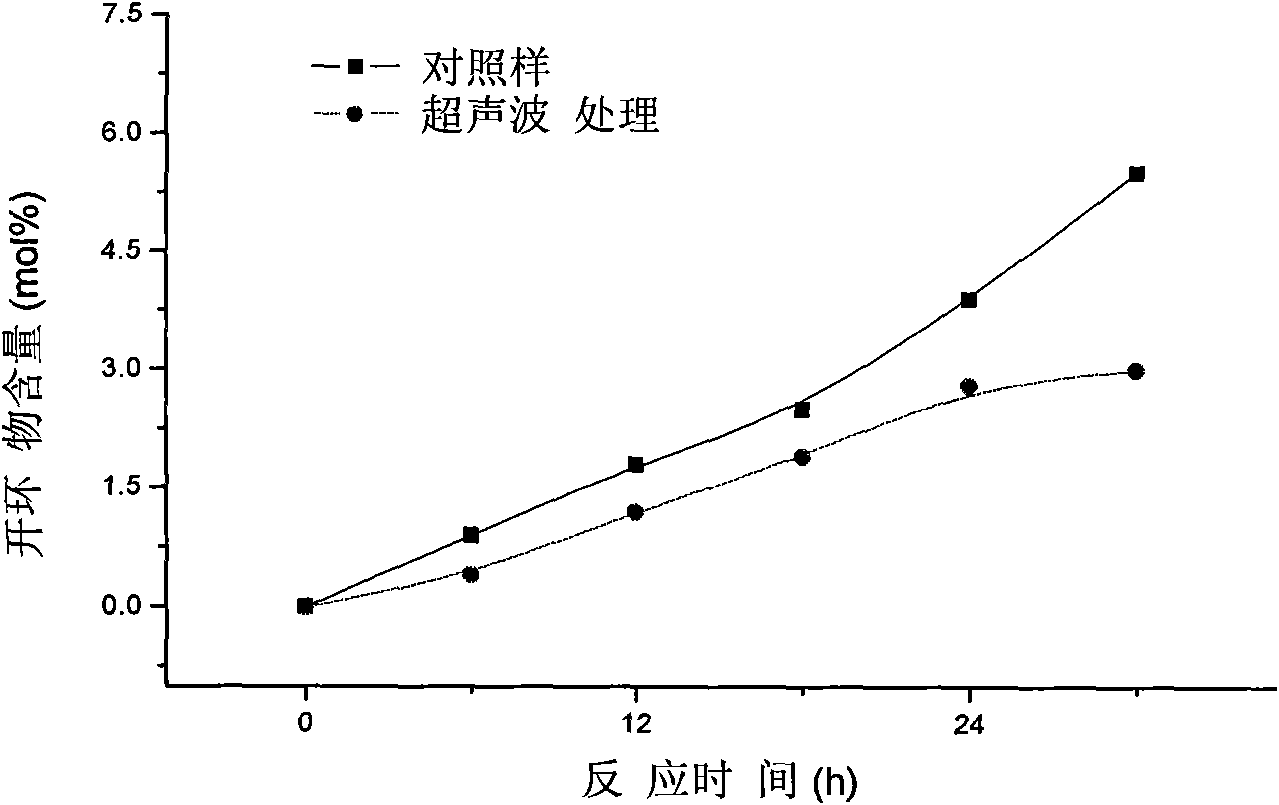

Embodiment 1

[0024] Taking by weighing 100 parts of total solids content is the concentrated natural rubber latex of 60%, the concentration of concentrated natural rubber latex is diluted to 30% with deionized water, adding 3 parts of concentration is 20% polyoxyethylene laurate, makes latex keep stable 2 hours later. Then, 21.6 parts of formic acid with a concentration of 86% and 43.2 parts of hydrogen peroxide with a concentration of 30% were sequentially added under stirring, and reacted in a water bath at 50° C. for 6 hours, and treated with 20 KHz ultrasonic waves for 10 minutes every 50 minutes. After the reaction, use a cold water bath to lower the temperature to room temperature, add ammonia water to adjust the pH value of the latex to 9, add ethanol to solidify, dehydrate, rinse, granulate, and dry. The prepared epoxidized natural rubber has an epoxidation degree of 12.6%, a ring-opened substance content of 0.4%, and a double bond content of 87%.

Embodiment 2

[0026]Taking by weighing 100 parts of total solids content is the concentrated natural rubber latex of 60%, the concentration of concentrated natural rubber latex is diluted to 30% with deionized water, adding 3 parts of concentration is 20% polyoxyethylene laurate, makes latex keep stable 2 hours later. Then 21.6 parts of 86% strength formic acid and 43.2 parts of 30% strength hydrogen peroxide were added successively under stirring. React in a water bath at 50°C for 12 hours, and use 20KHz ultrasonic waves to sonicate for 10 minutes every 50 minutes. After the reaction, use a cold water bath to lower the temperature to room temperature, add ammonia water to adjust the pH value of the latex to 9, add ethanol to solidify, dehydrate, rinse, granulate, and dry. The prepared epoxidized natural rubber has an epoxidation degree of 32.5%, a ring-opened substance content of 1.2%, and a double bond content of 65.5%.

Embodiment 3

[0028] Taking by weighing 100 parts of total solids content is the concentrated natural rubber latex of 60%, the concentration of concentrated natural rubber latex is diluted to 30% with deionized water, adding 3 parts of concentration is 20% polyoxyethylene laurate, makes latex keep stable 2 hours later. Then 21.6 parts of 86% strength formic acid and 43.2 parts of 30% strength hydrogen peroxide were added successively under stirring. React in a water bath at 50°C for 24 hours, and use 20KHz ultrasonic waves to sonicate for 10 minutes every 50 minutes. After the reaction, use a cold water bath to lower the temperature to room temperature, add ammonia water to adjust the pH value of the latex to 9, add ethanol to solidify, dehydrate, rinse, granulate, and dry. The prepared epoxidized natural rubber has an epoxidation degree of 49.5%, a ring-opened substance content of 2.8%, and a double bond content of 48.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com