Novel slab core forming machine of blister steel net wall body

A foam steel and molding machine technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of many production turnover procedures, occupying a large workshop area, raw material power, and labor consumption, etc., to achieve simple structure, high production efficiency, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

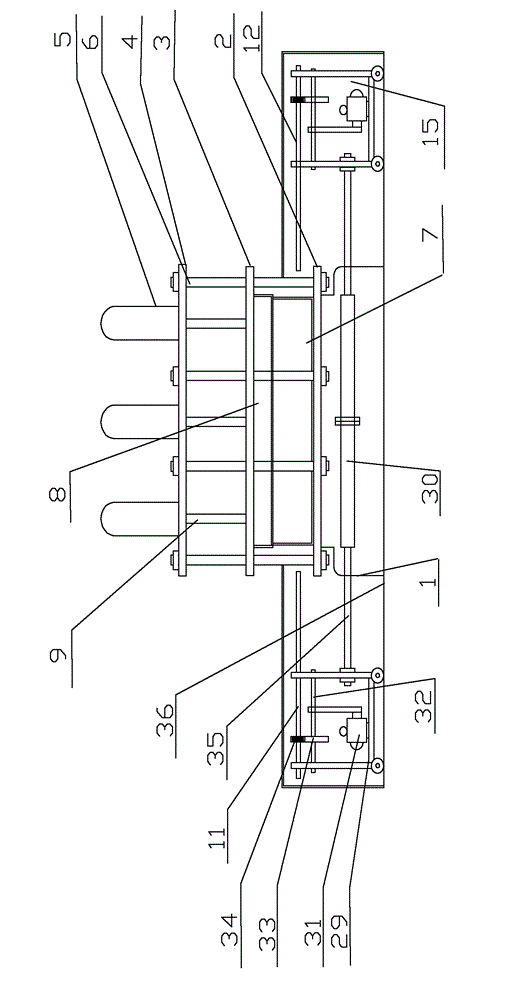

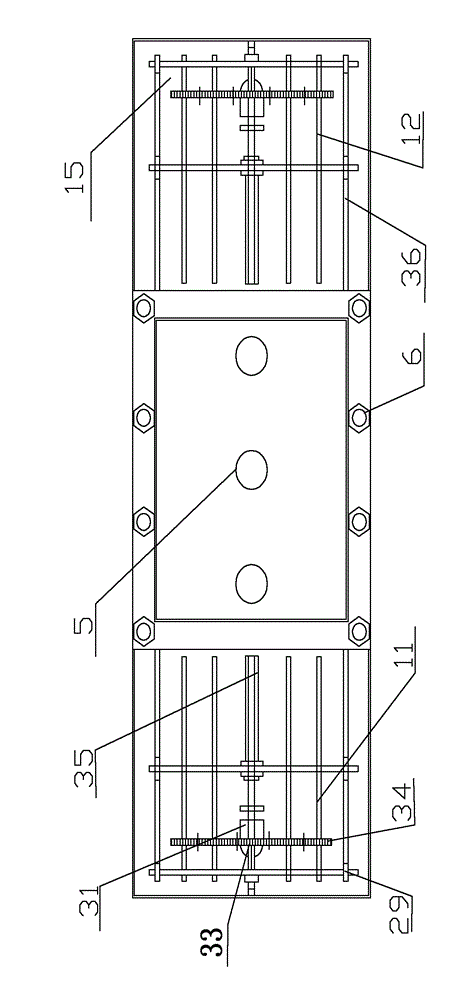

[0018] Attached below figure 1 , 2 , 3, 4, 5, 6 describe an embodiment of the present invention.

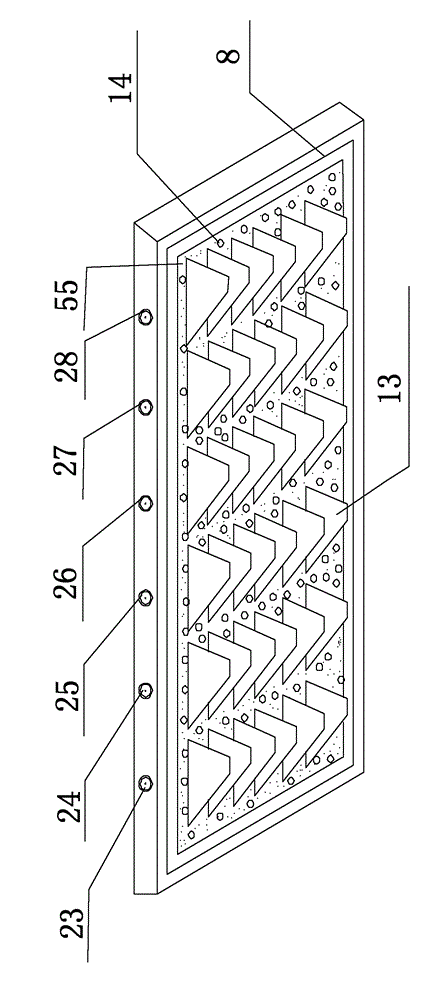

[0019] Foam steel mesh wall core forming machine, the lower static formwork 2 is fixed on the support 1, the guide column 6 is vertically fixed on the lower static formwork 2, the upper static formwork 4 is fixed on the top of the guide column 6, and the dynamic formwork 3 is set On the guide column 6 and between the lower static template 2 and the upper static template 4, the lifting cylinder 5 is fixed on the upper static template 4 and its piston rod 9 passes through the upper static template 4 to connect with the movable template 3, so that the movable template 3 Move up and down along the guide post 6; the upper end surface of the lower static template 2 is fixed with a static mold 7, and the lower end surface of the movable template 3 is fixed with a movable mold 8, and the movable mold 8 is located directly above the static mold 7.

[0020] Above-mentioned static mold 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com